I’m looking at Autodrop3d, a company that seems to offer automation solutions for 3D printing.

The Connecticut-based company started in 2016 and has been attempting to solve some of the most common problems encountered when operating farms of 3D printers.

3D Printer Farms

Farms of 3D printers are a solution used by several different industries:

- Manufacturers may use an array of 3D printers to produce low unit volumes of parts or products

- Educational institutions may operate a collection of machines for use by students doing projects

- Makerspaces sometimes deploy a series of 3D printers that require management

All of these scenarios and others face a few problems, including:

- How do you charge back use of the machines to users?

- How do you manage the dispatch of jobs to available machines?

- How can you efficiently unload completed jobs and set up for the next job?

None of these are typically included in 3D printer product offerings, as for some reason most 3D printer manufacturers assume there is only one person operating a single machine. That’s still the default, but there are an increasing number of situations where farms of machines are used.

Autodrop3d

Autodrop3d attempts to address some of these issues with both hardware and software solutions. They offer a cloud-based system that can connect to a collection of 3D printers and perform basic management, for example.

They also offer an intriguing system for automatically unloading 3D print jobs. They don’t say much about it on their website, and I am keen to learn more about how this works.

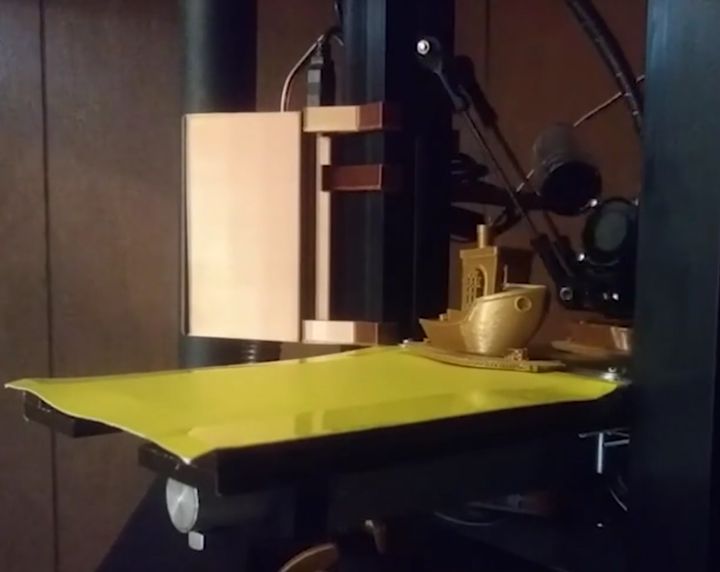

They do provide a short video of how the process works, however:

While the device is producing objects serially, apparently without human intervention, it is completely unclear how this is happening.

In another short animation you can see a bit more:

As you can see in the image, it appears that they have a kind of bulldozer-blade that pushes prints off the print bed. That’s not a bad solution, and is somewhat similar to an approach I saw a few years ago where special GCODE used the printhead itself to knock prints off the bed. However, in this case Autodrop3d has built custom hardware to implement the pushing mechanism.

Their cloud software seems to focus on the user experience: a user can upload a 3D model to the cloud system, select a material and then the job is sliced and dispatched to an available 3D printer in the array.

The system also includes an ability to create CAD models from scratch and uses a parametric paradigm.

What’s unclear is the method of buying this service. Their website has no information about subscription fees, but does offer two delta-style FFF 3D printers for purchase. These come with “one year” of Autodrop3d Cloud, but it’s not clear how much the fee will be after that, or whether there are discounts for larger quantities of devices.

They also offer a US$229 set-top box that is designed to attach existing 3D printers to their cloud, but again it is unclear whether you need one of these boxes for each 3D printer, or whether the set-top box can connect to several at the same time.

The concept Autodrop3d is pursuing seems like a good one, but I think they need to clarify a few things before they will be able to attract customers with larger quantities of equipment.

Via Autodrop3d