Lighting has always been a consistent issue with 3D printers, and it doesn’t seem to be improving.

The early desktop 3D printers, and many still today, were open format devices. These would appear to be a gantry upon which a motion system was mounted. As the print proceeded, one could easily see the operations take place from almost any viewing angle.

But then we started to get enclosed 3D printers, and for good reason: the enclosures allow the capture of stray heat from the build plate, which raises the ambient air temperature inside the machine. This reduces the thermal gradient — or gap — between the extrusion temperature and the temperature of the model itself. Reduced gradient means less warping.

The enclosed approach allows the practical use of many more advanced 3D print materials. ABS, for example, was — and is — notoriously challenging to 3D print on any open format 3D printer. The same can be said for other quirky materials, like nylon. However, it’s a great deal easier when using an enclosed 3D printer, particularly if you let the chamber heat up a lot before starting the print.

However, there’s a problem: many of these enclosed devices have very limited viewing angles, as there is usually only a window on the front to observe operations. Some enclosed machines have clear plastic walls, which is somewhat better.

However, almost all of them suffer from poor lighting. Even if there’s a straight line from your eyeball to the extrusion surface, it makes no difference if it’s too dark to see. This problem is aggravated by the sometimes enormous housings enclosing the hot ends. These take up so much space there is only a very small angle through which you can observe the beginning of the print job.

That beginning portion is of critical importance. I can tell you that I never leave a print job until the first layer has successfully been put down. Why? Because that’s the layer that determines if the adhesions is likely to hold. If you can get through the first layer, there’s a good possibility the rest of the job will proceed normally, unless there is severe warping or other issues later on.

You’ll find me sitting in front of the 3D printer carefully watching the first layer extrude. Sometimes it’s very difficult because of the poor angles and often absent lighting. Because of that I almost always have a bright movable lamp positioned beside the machine that I can use to better observe activity.

If only 3D printer manufacturers would put lights in their machines, this could be a lot better. However, some actually do put lights in their machines – but almost universally they are too dim and don’t illuminate the “active” part of the print bed when the hot end is over top.

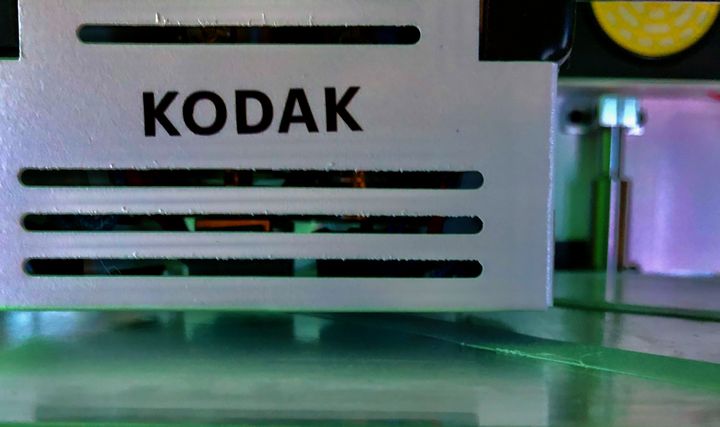

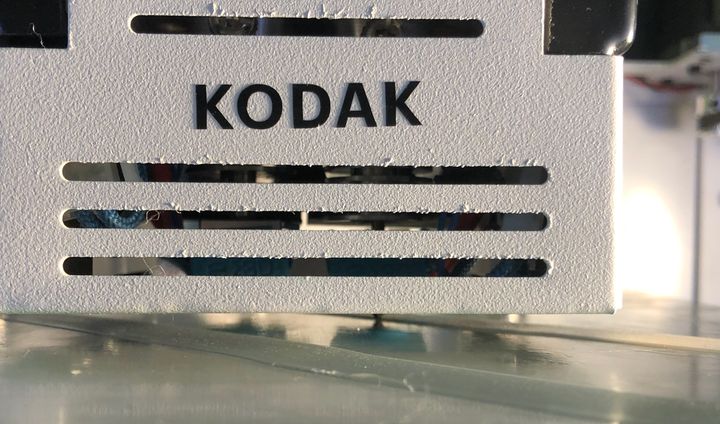

Some 3D printers, like my Kodak Portrait, have a lighting system that like most others, is insufficient. However, it does change color to indicate whether the job is heating, in progress or completed.

Here’s a view of the Kodak hot end during 3D printing, and yes, the diffuse lighting is turned on.

And here’s another view with an external light added. You can now see the actual extrusion easily, which is otherwise in the dark.

I’m not sure what the solution is here, aside from perhaps attaching a light source directly onto the moving hot end: that would definitely brighten things up sufficiently, and it would not likely not cost a great deal: the light source would be close to the active area and so a relatively low power light would be sufficient.

Hopefully some 3D printer designers will read this story and consider improving the lighting on their equipment.