Zortrax worked with the European Space Agency to successfully 3D print and test a conductive high-temperature material.

PEEK is becoming very popular in 3D printing due to its durability and very high heat resistance. It is a true production material that has opened the door to manufacturers’ application of it for end-use parts.

One property not normally present in PEEK is conductivity, and thus there is no ability to transmit power or signals.

It turns out that ESA had a need for such functionality for future space missions. That makes sense, because PEEK offers heat resistance that would handle the extreme heat and cold experienced by space vehicles.

ESA developed a new conductive form of PEEK and asked Zortrax if they could possibly 3D print parts with it for testing. The Polish company took up the challenge and apparently succeeded.

They say:

”Back in 2018, the ESTEC team published a research paper describing an electrically conductive PEEK 3D printing filament. This way, PEEK, which normally is not a conductor, has been redesigned to work as an energy or data transfer material. The team achieved this through mixing PEEK with carbon nanotubes and graphite nanoparticles in just the right proportions to facilitate conductivity. The only missing piece was a 3D printer that could work with this material to make conductive paths in a standard PEEK body. Since there was no such 3D printer on the market, Zortrax launched a research project to make this work. And this research project has just turned successful.”

There have been conductive filaments devised in the past, and these have allowed some experimenters to 3D print objects that contain rudimentary embedded circuits. However, due to the resolution of 3D printers and the relatively poor conductivity of these filaments, the conductive paths must be relatively large.

ESA Conductive PEEK

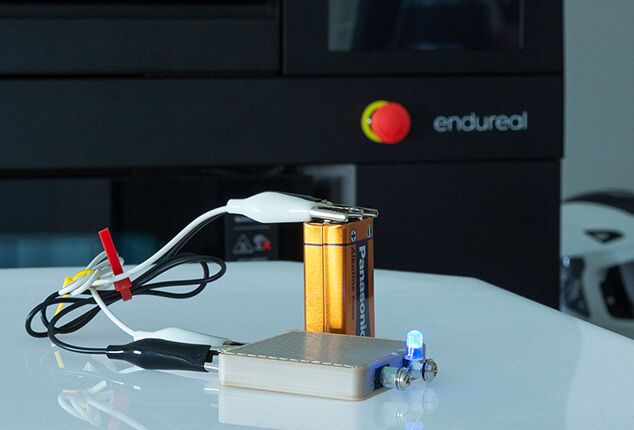

The new material was tested by Zortrax using their dual-extrusion device, the Endureal 3D printer. This device is able to 3D print in two different materials, and just happens to be high-temperature capable, too.

The Endureal’s hot ends can hit 480C, the print surface 220C, and the enclosed build chamber 200C. These temperatures make the device fully capable of 3D printing exotic materials including PEEK.

The conductive PEEK material from ESA was simply composite material, with PEEK doped with additives that create the conductive effects. Thus it could be 3D printed in the same manner as normal PEEK on the Endureal.

The testing was able to 3D print conductive traces that were able to perform two electrical functions: transfer power and transmit signals, both of which could be required in future space missions. Zortrax explains their results:

“Using the Endureal’s dual extrusion technology, we have made the world’s first data transfer device 3D printed entirely out of PEEK polymers. A data transfer of 9600 bit/s has been achieved between two computers connected with USB cables and USB RS-232C converters through a 3D printed model. We have also fabricated models with built-in electrically conductive paths.”

One of the key challenges faced by Zortrax in this experiment was to ensure the absolute accuracy of nozzle alignment. If they were not precisely aligned, then conductive PEEK deposition might have been slightly off position, and that’s not a good thing when you have electricity running through these extrusions. However, it seems they were able to align things properly and the prints succeeded.

With this successful experiment, the door now opens for the production of lightweight high-temperature parts that can perform electrical functions. These single-piece parts could simplify assemblies significantly and offer unusual new opportunities to develop.

They say that space programs can develop spin-offs, and I do believe this is one of them.

Via Zortrax (Hat tip to Benjamin)