COVID-19 has been a substantial part of our lives for the majority of this year and we’re very thankful for all of the innovators who took the initiative to help alleviate the impact of this pandemic.

3D Printing For Pandemic Response

COVID-19 cases have surpassed 37.3 million worldwide as of October 11, 2020 and the 3D printing community has definitely taken a stance in helping overcome this battle. As of May 14, there was a minimum of 164 3D printing initiatives as a response to the global pandemic. Let’s take a look at three impressive such innovations / initiatives.

3D Bioprinting Mini Organs

The team at Wake Forest Institute for Regenerative Medicine, led by Dr. Anthony Atala, has developed miniature organs to ease treatment testing.

Back in 2011, Kerry wrote a story where Dr. Atala described the potential future for bioprinting. The organ analogs include those of colons and lungs and offer a testing platform without the involvement of humans or animals. The mini organs bear a much closer resemblance to human organs than the mammals that are usually used for testing. Studies on humans are very time-consuming and hard to monitor as the patient must be constantly monitored to make, whereas these printed organs can be observed consistently.

Although this is in no way equivalent to 3D printing full organs, it’s definitely a step in the right direction and has the potential to hasten the development of a COVID-19 treatment. Initially, Dr. Atala’s team had been able to create these analogs manually with the help of tiny pipettes, but with the demand for COVID-19 treatments, the team has automated the production of these bioprints and are capable of producing “thousands per hour”. Ultimately, their discovery helps the transition from animal and human testing to remote, lab based testing with equally as accurate, or more accurate results.

Read more about this bioprinting effort here.

Open Source Tools To Aid In Battling COVID-19

The Michigan Tech’s Open Sustainability Technology (MOST) Lab has released not one, but three open source tools as a response to the global pandemic.

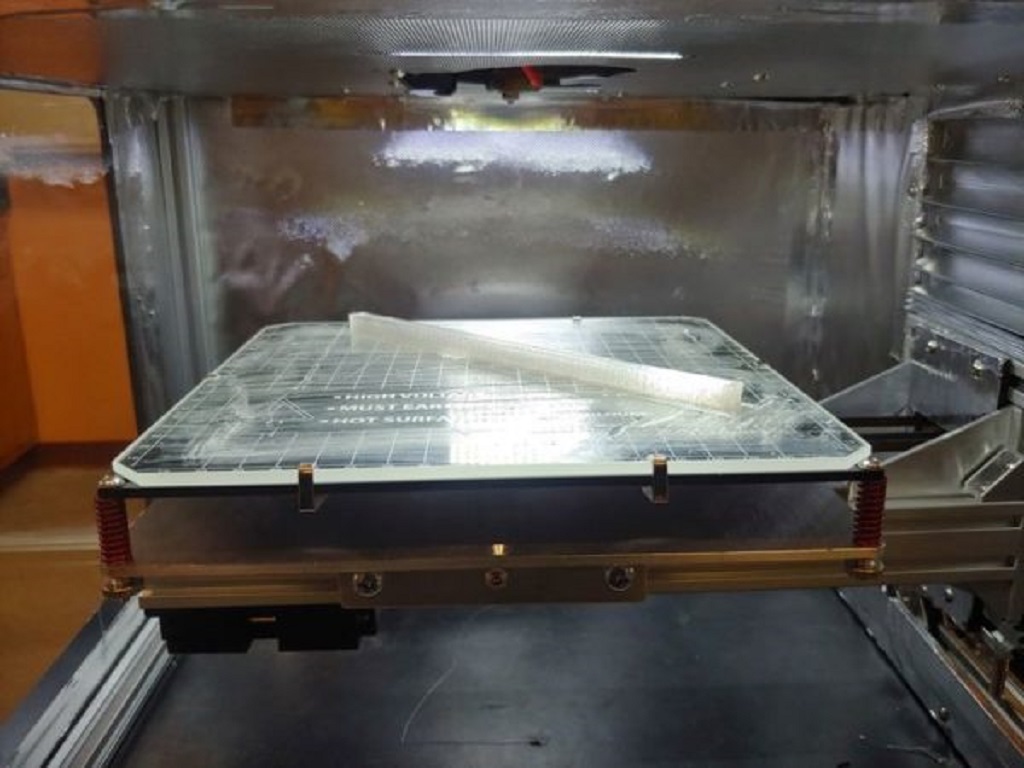

The first of which — the Cerberus — is a high-temperature 3D printer. With this 3D printer’s affordable assembly (it can be made for less than $1,000 in parts) and high heat capacities, it could be used to 3D print equipment and personal protective equipment for hospitals (as they could be sterilized under high heat and reused) in times of shortage. Their second masterpiece — a powdered air-purifying particulate respirator (PAPR) — is a respirator intended for use by first responders. The PAPR has a controllable air flow and allows users to continue breathing even if the fan is disconnected or if the battery dies. This open source invention can be assembled for a mere $150 and meets the airflow requirements for the National Institute for Occupational Safety and Health (NIOSH) for four hours. Their final open source product is a ventilator that can be 3D printed for under $170 and is a resuscitation system. It comes with different modes, allowing manual control over tidal volumes and breathing rates. Experimental results show that the repeatability and accuracy demonstrated by this ventilator exceeds human capabilities in BVM-based manual ventilation.

Further detail on all three of these tools and the applications that they promise available here.

Coordinating COVID-19 Parts Production

With a novel virus like this one, no one really knows exactly what to do, so we closely watch the situation and the responses of others to make decisions.

We are thankful to a team in Huntsville, Alabama for taking an early lead and coming up with an organized and practical method to face the virus. There are many factors to take into account when designing parts, including disinfection, accessibility, delivery, cost, quantity, ease of assembly, and of course necessity. Destin Sandlin of Smarter Every Day produced a fascinating video detailing the approach he used to organize a face shield production and delivery operation in Huntsville. Sandlin’s production line featured an intelligent drive through system, a packaging system for boxing, instructions, etc., and a sophisticated disinfection plan. We are so proud of this initiative and the example that it sets for everyone.

You can find out more from Kerry’s article focusing on this initiative, as well as the video:

A Final Note

Once again, please note that these initiatives are just three out of hundreds more — all of which we are thankful for. With the pandemic’s reach, all sorts of help and contributions are welcome and encouraged, because this is a time to come together and help each other out.

There are many things unique to the 3D printing industry which cannot be offered by anyone else and we encourage you to take advantage of this opportunity to offer a helping hand. If you are interested in sharing your expertise, take a look at our articles on some advice to makers working on COVID-19 projects and on where to offer your skills.

Happy (Canadian) Thanksgiving everyone!