The world is about to see a deluge of belt 3D printers but can they be economically used for low-volume manufacturing?

I’ve written multiple pieces lately about belt 3D printing, which I believe will be a big thing in the future, particularly after the release of the low-cost 3DPrintMill. While some doubt the need for such a device, the notion of 3D printing large objects on a small device is intriguing. What’s even more provocative is the concept of low-volume manufacturing with belt 3D printers.

Belt 3D printers operate by 3D printing on a moving conveyor belt instead of a fixed plate. This allows the device to 3D print very long parts, so long as there is some apparatus to hold the part level as it emerges. There is also the possibility of continuously 3D printing smaller objects, and the belt simply carries them along. When the objects reach the end of the belt they automatically peel off and land in a bucket.

In theory you could 3D print objects forever, so long as you keep supplying material to the belt 3D printer.

Low-Volume Manufacturing

Low-volume manufacturing has been a concept in the 3D print world for several years, and it refers to the concept of producing a quantity of parts that’s less than the break-even point for making the same parts with traditional mass manufacturing processes.

This filled a gap where companies were unable to efficiently produce lower quantities of parts. They’d either have to raise their costs significantly to account for the overhead of producing injection molds, for example, or abandon the project. Instead it’s possible to produce the same units on 3D printers with a slightly higher unit cost than full-on mass manufacturing right away.

That business model has caught on and today we see many service bureaus using it on arrays of 3D printers.

Economics of Low-Volume Manufacturing

With the soon-to-be-shipped 3DPrintMill, the world will gain access to a low-cost belt 3D printer, and it will inevitably be used to produce low volumes of parts.

But how much does it really cost to produce parts in a low-volume manufacturing scenario in either belt or non-belt 3D printing environments? Let’s take a look.

For analysis purposes, let’s say our “product” is a #3DBenchy. Let’s also say this object takes 90 minutes to print, regardless of whether it’s done on a normal 3D printer or a belt 3D printer.

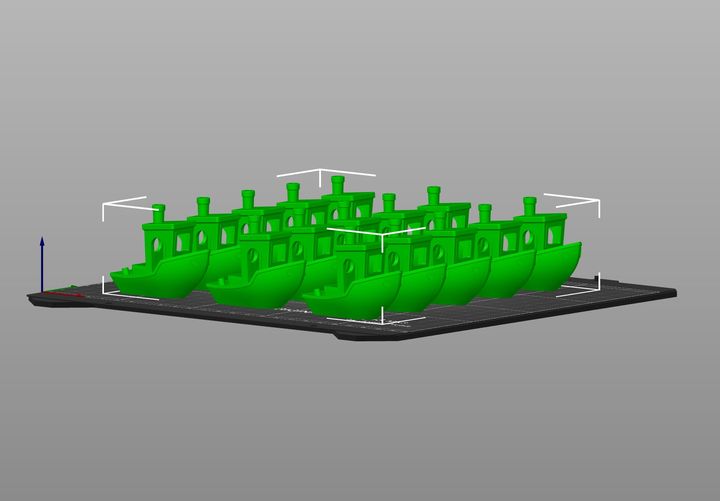

On the normal 3D printer, we’ll 3D print 15 Benchys per plate, but on the belt 3D printer we’ll 3D print one at a time, but continuously.

The normal 3D printer will take 21 hours to complete the job, and require about 200g of filament per job. The belt 3D printer will produce one unit every 90 minutes and consume 13.5g of material.

Over the course of a week, we’d have the following scenario:

- Normal 3D printer: 8 jobs completed, 120 units produced, 1.6kg material used.

- Belt 3D printer: 112 units produced, 1.5kg material used.

This seems pretty close: similar numbers of units produced, and one filament change along the way if 1kg spools are used.

However, there’s another issue: labor requirements. At each job completion on the normal 3D printer an operator must be present to unload the 3D printer, scrape off the debris from the plate, reset the plate, and start the next job. There will be a delay as the plate and 3D printer heat up before commencing the second print job. How long does this take? I’ll estimate ten minutes.

This means that the normal 3D printer would suffer a deduction of 80 minutes to the week’s work, and so only 7.5 jobs would be completed. Or, at the finish line, 105 units would be done.

There’s also the problem of failures. Should the belt 3D printer mess up a print, it would simply be carried off into the collection bucket, and the next unit would start anew. Meanwhile, a failure in the normal 3D printer job would imply a loss of all 15 units, and worse, a loss of 20 hours of work time.

The difference between these two options is really the operator time required. While the case above there would be an hour or so spent by the operator, it requires the operator to be available at the machine precisely when each job completes, which could be at any time during the 24-hour cycle. That’s not practical for anyone, and it’s likely some completed jobs will sit until the operator shows up at the start of their shift.

This effect is exacerbated when you increase the volume. Now let’s say we have ten 3D printers of each type producing the same units.

During a week’s production, the belt 3D printer would require ten filament swaps only. It’s also possible to use 2kg spools and eliminate that work entirely, too. Not much to do here.

Meanwhile, the ten normal 3D printers would require 800 minutes of labor (13.3 hours) to produce the same quantities. That is a day and a half’s pay, but is spread out over the entire 24-hour cycle so it’s really going to be many more hours of pay involved.

The bottom line here is that the ten normal 3D printer will require labor to operate in excess of the price of the 3D printer — each week!

We don’t know the price of the 3DPrintMill yet, but rumors suggest it may be about 4-5X the price of a typical 3D printer. To me this suggests about US$1000 vs US$200. That US$800 difference would be eventually made up if the belt 3D printers could operate continuously over the course of a few months.

It seems to me that a low-volume manufacturing operation could have a considerable advantage if they could effectively use them at volume.

What do you think? Will you get a belt 3D printer?

Hello there,

As always a very good article.

Belt printers are really attractive. In my case i am regularly printing small batches (500 pieces each) of parts. One build plate on the MK3 takes 9 hours to print 12 pieces in subsequent print mode.

When i think of a belt printer it definitely will make my workday easier as i would not have to start new prints every 9 hours.

Sadly i have no confidence to run a printer by Creality or other manufacturers selling cheap printers. Creality just showed that even with many years of experience producing printers they cannot ensure that the devices are save to operate (see the kickstarted Ender 6SE) and i do not want to burn down my property just because of the comfort of not having to change the sheet every so often.

Basically i am waiting for a belt printer by a company i trust, and there are not much of them. As for me only Original Prusas produce repetitive results that are always same and with a qualitiy that i can sell to customers i am not seeing me buying that printer. Even though i thing that Naomi Wu puts lot of effort to ensure that “her” ptinter wont suffer safety issues.

Additionaly the downtime on Prusa printer because of maintenance is neglectible. Once setup good the just work. Only thing that has to be done from time to time is change the brass nozzle to ensure qualitiy of the prints, even when only printing non abrasive materials.

Best regards

Sebastian