I spoke with Chengxi Wang of Satori to find out more about their newly launched resin 3D printer.

Wang is the CEO of the newly formed company that has developed a highly usable resin 3D printer that’s targeted at professionals. While the machine will be usable for a variety of purposes, the company is initially focusing on the dental market.

Of course, I asked which part of the dental market they were targeting. There are two major segments: the dental lab industry, and individual dentists. Wang explained they would work with both but really want to focus on the individuals, and that’s where their unusual strategy comes in.

Wang is one of those highly creative people you sometimes encounter, and she’s been involved in 3D printing for a few years now, having been the CEO of MyMiniFactory. In that role she ensured that service allowed its users to succeed in deploying their 3D printable art online.

Chengxi Wang on Creativity

Wang explains her thoughts on creativity:

“People usually think 3D printing has nothing to do with them. They don’t realize how close 3D printing is to their lives. It’s not a fancy technology you randomly use; it requires people to collaborate to unleash their creativity.

Many people lose their creativity due to our exposure to mass manufacturing, and we’re losing our ability to imagine. At Satori, we want to enlighten people to go back to owning their creativity. Our role is to provide the means for them to do so.”

How does this apply to marketing a 3D printer? Wang explains Satori’s strategy:

“I’m a big fan of creativity back to my days as a singer. I like to see an idea actualized, and 3D printing is a tool for that without the requirement for finding a manufacturer. However, often people with 3D printers that have a quality idea simply cannot make it happen.

There seems to be a lower tier where people figure things out themselves, and a higher tier of larger companies with skilled staff. There’s a gap in-between.

My team helps them navigate the machine to where they want to go. I asked myself what is the pinpoint for dentists? Not what technology but how to get them there.”

As such, the Satori team has built not only a resin 3D printer, but also a consulting “partnership program” that ensures the buyers are always able to use the machine productively.

But why the dental market? Wang explains:

“No business wants to limit its potential, especially at the beginning, but we had to focus. I went through this struggle. Dentistry is a niche market, but we needed to set a pinpoint target. Our ambition is to eventually cover more audiences, but we must start from somewhere.”

After deciding to target dentists, Wang spent considerable time with dentists to understand their needs and workflows. After a time, she began to understand their “user journey” in 3D printing. Then the larger Satori team was able to build a solution that addressed those needs.

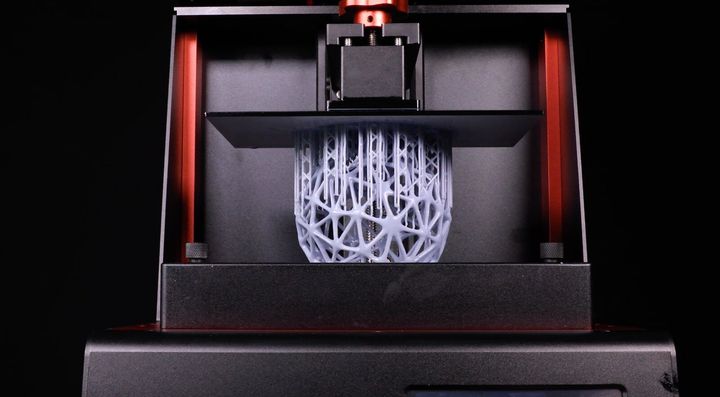

Satori ST1600 3D Printer

The ST1600 they developed is a resin machine, as is commonly seen in the dental industry. It’s designed by the Satori team in London, but is manufactured by the company’s staff in China.

While it can be used for other purposes, their initial dental market target meant they would start with a series of dental resins.

At launch they offer six different resins that are each specific to dental use. This means that buyers are immediately able to produce any types of 3D prints required in their dental business.

The ST1600 uses a 4K light engine that illuminates a 192 x 200 mm area, ensuring very high resolution. It’s also quite fast to print, as Satori says it can 3D print seven dental aligners in about an hour.

Costs of the ST1600 are interesting. The company offers two options: a basic version and a bundle version.

The thinking here is that many of their clients are those who have never used 3D printing previously, and want to experiment. For them they offer a machine with a single bottle of resin and 14 days of consulting for £2900 (US$3700). These buyers can try out the machine at a lower cost.

For other operations that are more familiar with 3D printing and are confident in the device there is the bundle, which includes a machine and 36 bottles of resin of their choice. Wang told me their research showed that typical “farm” use of the printer would consume around 36 bottles per year. Thus, a ST1600 and one year’s worth of supplies costs £5410 (US$7000).

Currently the machine is available at their online store, but Wang tells me they are soon to open a kind of demonstration center at their London office to enable curious dentists to physically see the machine and process involved.

My thinking is that Satori is entering a busy market, as there are plenty of dental competitors in the space. However, they do have a very powerful strategy that focuses on ensuring clients make practical use of the equipment for their business.

And the low cost doesn’t hurt, either.

Via Satori