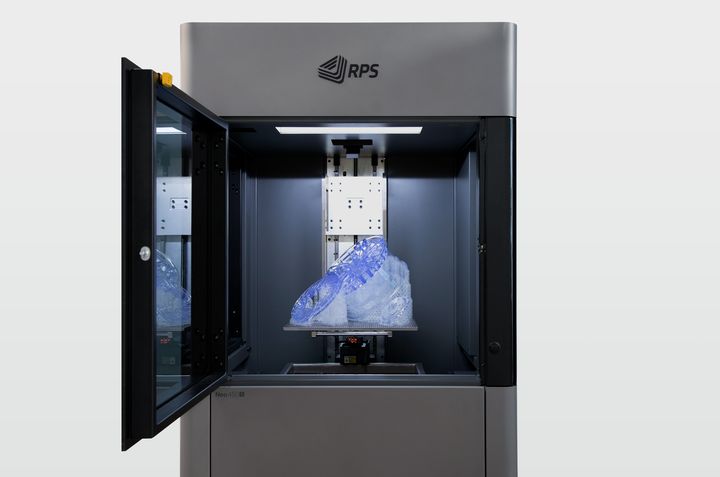

UK-based RPS announced a new series of industrial 3D printers, the Neo 450 line.

The company was well-known for its flagship 3D printer, the Neo 800, which we saw in person last year. That machine has quite a large build volume and produces outstanding parts as well.

Neo 450 Series

Now the company has announced a smaller version of their technology packaged into the Neo 450 line. There are two models, the Neo 450e and Neo 450s:

- The Neo 450e is an affordable industrial-grade 3D printer producing small to medium parts with consistent accuracy and repeatability. Dependable and reliable, the Neo 450e is designed for non-stop printing of industrial production parts.

- The Neo 450s offers performance and versatility along with all the benefits of Neo 450e. Producing superior quality parts, the Neo 450s is up to 40% faster than the Neo 450e and offers standard (SD) and high definition (HD) build modes. Supplied with a more powerful laser, 3-axis dynamic scanning system and advanced software algorithms, the Neo 450s can quickly print SD or HD parts over the entire work area, all with outstanding accuracy and detail.

The Neo 800 is able to produce very high-quality prints with apparently 1 micron positioning. This is due to its incredibly rigid construction, and it seems this approach has been duplicated in the Neo 450 series.

This resolution is beneficial in not only visual and tactile appearance, but also quite significant in post-processing: the smoother print surfaces mean there is less time required in post-processing steps where parts are smoothed with tumbling or other processes.

The big difference between the Neo 800 and Neo 450 series seems to be the build volume. While the Neo 800 can build within an 800 x 800 x 600 mm envelope, the 450’s build volume is smaller at 450 x 450 x 400 mm. Still quite large, but smaller than the enormous Neo 800.

3D Print Smaller On Neo 800

Why offer a smaller industrial 3D printer? RPS’ CEO David Storey explains:

“With the Neo450 series, we wanted to design and develop a reliable, versatile machine that offered customers more functionality. With the Neo450e, customers can produce complex industrial-grade quality parts from an affordable 3D printer. With the Neo450s, customers can now quickly produce small to medium parts in SD or build intricate HD parts over the entire build area.”

In other words, it seems they identified a market niche for this product at a lower price point. By shrinking the machine down slightly they are now able to access that market with the 450 series.

I have a suspicion about how this came about. One of the features of the Neo 800 was a special mode in which the operator did not have to fill the entire resin tank. That’s an expensive proposition as that machine’s resin tank required a massive 555L of resin. To put that in perspective, at US$200 per liter, that would cost something close to US$100K in resin!

The “small” mode allowed Neo 800 operators to use a much smaller amount of resin for smaller jobs. This meant Neo 800 operators didn’t have to purchase an additional smaller machine. However, it seems that some of RPS’ clients did indeed wish to purchase a smaller device. It may be that prospective buyers could not justify the price of the Neo 800, and rather than loose them as clients entirely, RPS intiatied development of the Neo 450 series.

We’re told the Neo 450 series is available now.

Via RPS