Charles R. Goulding and Preeti Sulibhavi pay homage to the late inventor of Gore-Tex and how his legacy continues to inspire work in 3D printing.

In his vacation home in California, Robert Gore died on September 17, 2020 at the age of 83.

Nobody thought that a piece of plumbing tape, similar to Teflon, could be transformed into a wearable, stretchable, weatherproof material. Yet now that piece of material is commonly used in everything from sports clothing to medical devices. This material, referred to as Gore-Tex, can serve all these functions. This patented technology that utilizes an expanded form of PTFE, referred to as e-polytetrafluoroethylene (ePTFE), was invented as a result of many failed attempts and much frustration. As the saying goes, “invention is 99% perspiration and 1% inspiration.”

Since Bob Gore created ePTFE, the patented microporous material has been used as a laminate layer in fabrics as well as material for medical implants, industrial filters, packaging for biologic drugs, fuel cells for electric vehicles (EVs), and uniforms for emergency responders. How many substances can you say keep your garments waterproof while providing the flexible chemical layers to repair a tiny human heart?

Just like the nature of his invention, Bob Gore expanded his father’s business. Not taking anything for granted, Bob took a relatively modest company and made it the billion-dollar giant it is today.

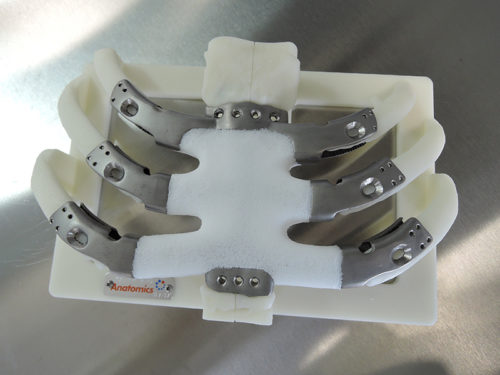

Gore-Tex utilized 3D printing technologies as well as collaborating with 3D partners that utilized the Gore-Tex material to serve various purposes ranging from industrial to medical. For example, the sternum of a 20-year-old woman was successfully replaced utilizing a 3D printed sternum that utilized Gore-Tex and bone cement implants. A child, born with a small hole in her heart, had a Gore-Tex “patch” stitched over the defect that was developed utilizing 3D printed heart models. Gore-Tex has touched everything from weatherproof clothing to the human heart.

Research and Development Tax Credits are available for the eligible U.S.-based, 3D printing activities that Gore-Tex and its business segments engage in.

The Research and Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Withstanding All Sorts of Weather

To have an impact on so many lives and so many levels is truly a remarkable achievement. Bob Gore’s legacy is one of determination, ingenuity, and innovation. Gore was truly a pioneer in the chemical engineering industry. His work also expanded 3D printing to serve new purposes and solve critical healthcare issues as well. Gore’s legacy, just like his invented material, will withstand all sorts of weather.