Pittsburgh’s dedicated additive manufacturing production campus, Neighborhood 91, has gained its first anchor tenant.

An Additive Manufacturing Neighborhood

Pittsburgh is an interesting city. It sits on three rivers and is part of the Steel Belt — though these days, it’s more “Tech Belt”, as we saw a couple of years ago when RAPID + TCT was held in the city. There’s a lot of 3D printing happening in Pittsburgh these days in both academia and industry. And so it made some sense when last November Pittsburgh International Airport announced the latest addition to the city’s 90 established neighborhoods.

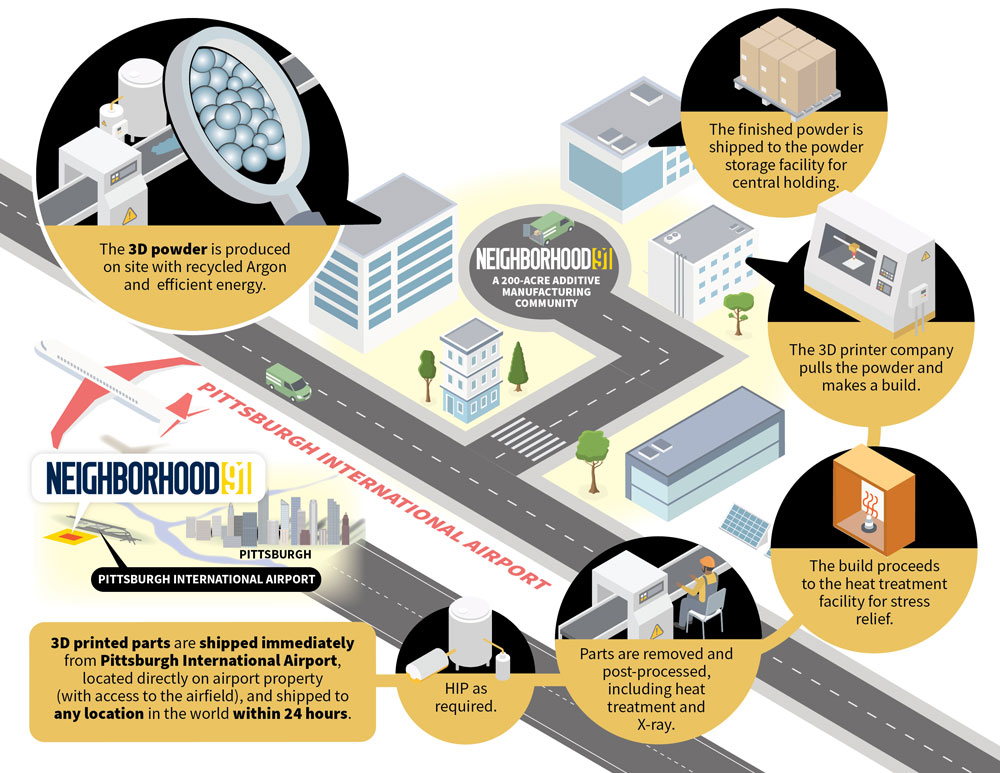

“Neighborhood 91 is the first development in the world to both condense and connect all components of the AM/3D Printing supply chain into one powerful production ecosystem,” the initiative’s website explains.

They also explain more of the concept in a splashy marketing-y video:

Neighborhood 91 is being built up now. The site, adjacent to the runways of Pittsburgh International Airport, is part of a 195-acre project called the Pittsburgh Airport Innovation Campus. The aim of the AM neighborhood is to “both condense and connect all components of the additive manufacturing and 3D printing supply chain into one powerful production ecosystem.”

“Part of our vision as an airport is to advance the region’s role as a world leader,” said Pittsburgh International Airport CEO Christina Cassotis. “Additive manufacturing is looking for a place to call home and now, with Neighborhood 91, that vision is becoming reality.”

The all-in-one configuration is looking to leverage the co-location of resources. Today’s announcement details these ecosystem resources as including:

- Powder, parts, post-production, testing and analysis

- Common powder storage facilities

- Efficiencies in production/post-production and delivery

- Tenants’ clients cost savings from on-demand printing

- Reduced transportation costs

- Airport access

- And perhaps the most important, argon, helium and other noble gases, which are essential elements of additive manufacturing, reaching up to 60 percent of additive manufacturing costs

Neighborhood 91 First Tenancy

To that last bullet point, the first tenant announced last autumn for Neighborhood 91 was Arencibia. The company describes itself as “a global leader in noble gas recycling for PM and AM applications.”

Joe Arencibia, President and CEO, Arencibia, explained some of his company’s strategy in joining the AM-dedicated neighborhood:

“While the concept of gas recovery as a multi-customer utility may seem novel, it’s a natural extension of what’s done at a number of Arencibia’s current recovery operations. Large, integrated customers in aerospace metals can have multiple argon users exhausting to a central gas recovery unit: sources like atomizers, presses, and heat treatment. The same customers may also have multi-point helium usage in plasma and cooling operations. In electronic materials, manufactures have dozens of tools with continuous demand for argon or helium, which are centrally recycled, as well.

The strategy at the Neighborhood 91 campus employs those same technologies, with a twist. Now a larger portion of the supply chain is co-located in a way that allows the central recovery operation to serve all scales of gas users,with inexpensive gas costs for all tenants. This creates a true, plug-and-play market for low-cost inert gases, with substantially reduced supply risk, and a low carbon footprint to boot.”

Neighborhood 91 Anchor Tenant

The AM neighborhood is growing more today, with Wabtec announcing itself as the first anchor tenant set to 3D print production parts for rail and transit customers. These operations will take place in a new 11,000-square-foot facility currently being built.

“Neighborhood 91 is designed for industry leaders like Wabtec to advance the application of additive technologies for their customers. By condensing the supply chain, this campus will accelerate the adoption of additive in the manufacturing space,” Cassotis said.

Wabtec has increasingly been growing its additive manufacturing strategy, including investing in new equipment. 3D printing for rail and freight is becoming a major focus, and Wabtec has been working with companies like GE to see that focus come to fruition. The Neighborhood 91 installation will complement existing 3D printing labs in Erie and Grove City, adding to Wabtec’s western Pennsylvania tech footprint.

Western Pennsylvania, in turn, has certainly noticed the ongoing area investment, as Allegheny County Executive Rich Fitzgerald said:

“Wabtec’s commitment to Neighborhood 91 is the latest example of our region continuing to move forward even in a pandemic. A Fortune 500 company, Wabtec’s decision to select Neighborhood 91 for its next manufacturing facility is a huge step for the development and Pittsburgh International Airport.”

For Wabtec’s part, the Neighborhood 91 expansion also makes sense. The company has announced intentions to produce over 25,000 parts via additive manufacturing by 2025. Among the transit rail production parts they have been targeting are “metal aluminum transit components like brake parts and heat sinks for freight locomotives.”

“Additive technology is a key focus area for us that provides new capabilities to drive innovation where traditional manufacturing could not,” said Eric Gebhardt, Wabtec’s Chief Technology Officer. “This agreement continues our investment in resources that enable our engineers to design new and complex products for the industries we serve. As the first development in the world to connect all elements of the additive manufacturing supply chain into a single location, Neighborhood 91 is the ideal location to fully realize the potential of this technology.”

The all-in-one neighborhood installation is a first-of-its kind in condensing an entire ecosystem into a single site. With more tenants, there’s hope that by the coming spring we’ll be seeing some interesting production additive manufacturing emerging as the airport-based neighborhood really begins to take off.

Via Neighborhood 91 and Wabtec