South Australian company Fusetec 3D prints body parts for medical training purposes. They hope to ramp up production post COVID-19.

Current Procedures

Generally, training courses for surgeons use the bodies of those who have passed away (cadavers), so that surgeons can gain practice working with the real body as it is.

Cadavers, however, can be difficult to source in large quantities — especially those with a specific, existing health complication. A global conference in Adelaide in November used 168 noses and 40 heads to train surgeons across the world.

Fusetec’s Sinus Models

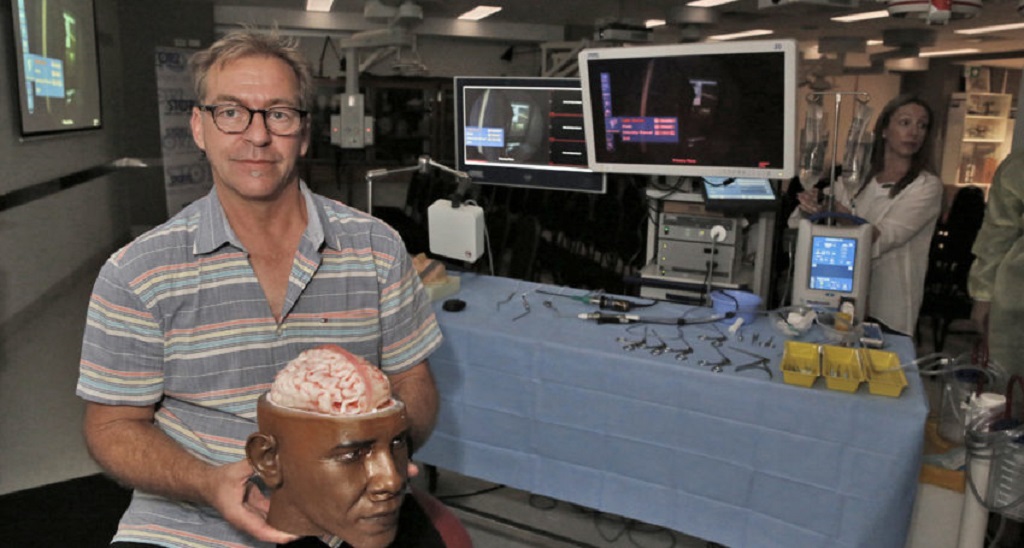

Fusetec’s sinus models feature textures that closely resemble layers such as skin, tissue, and bone, allowing surgeons to receive a high-class training experience without the use of cadavers. In the past year, they have presented their newly created full head at medical conferences worldwide. The final product can be modified to include pathologies such as tumors for extended practice in their removal or treatment.

The first commercial course that utilized Fusetec’s models was offered in Montreal (September), with a similar course following suite in New Orleans. Fusetec CEO Mark Roe explained that he had planned to present this sinus model at a conference in Milan, before COVID-19 paused travel and major events.

He told The Lead:

“We’ve been shipping the sinus products around the world but as soon as that first product was endorsed and accepted by the market, we started developing the rest of the anatomy and that’s what we’re doing at the moment.

Our objective is to create a complete library of human anatomy with pathologies so that’s what we’re working towards during this period.”

Future Directions

Roe believes that surgeons are slow to adapt to new technologies, but expresses his confidence that they will do so in the weeks following the end of COVID-19.

He explains, “We have taken a bit of a short-term hit with the rolling out of our products but in the long term it will be a benefit to us because it will alert surgeons to the risk of bacteria and cause them to look for alternatives to rehearse and practise their profession on.”

Australia’s Advanced Manufacturing Growth Centre and the University of South Australia’s Future Industries Institute have presented Fusetec with grants as well as the responsibility of making the manufacturing process for products such as the sinus model less time-consuming and more efficient.

Applications

My introduction to this field was through a very similar project. In my Fabbaloo intro post, I talk about this project in more detail. Basically, it was a brain model that allowed general surgeons to practice, so that they would be prepared in the case that they had to perform an emergency craniotomy. In rural communities, it’s very difficult to find specialized doctors in a short amount of time, so tools like this sinus model will help all surgeons get a general idea of what to do when the need for a specialized surgery arises.

Fusetech is far from the only company to have explored the 3D printing of organ simulations. For example, Wake Forest Institute 3D printed miniature organs to test COVID-19 treatments, and SynDaver, a company dedicated to making synthetic cadavers, relatively recently entered the 3D printing industry. Of course there are tons of others that we have written about on Fabbaloo, but I think that the message that we need to take away is that this technology is applicable everywhere.

It isn’t an opportunity that’s unique to neurosurgeons. We’ve printed miniature functional organs and life-size organs that feel the same texturally as organs inside the body. I’ve seen so many projects trying to make a functional pancreas for diabetic patients and when we can print an accurate model of a complex organ such as the brain, it’s definitely worth giving it a shot.