I had a thought about how belt 3D printing might play out in the future.

Belt 3D Printing

Belt 3D printing, if you haven’t been paying attention, is a new form of 3D printing that has only recently been developed. While it still uses the long-familiar plastic extrusion process (FFF), it does so by 3D printing at an angle.

The angle allows the 3D printing to take place on a moving conveyor belt to produce objects of the same quality as normal 3D printing. However, the moving belt implies that axis has infinite length and so a belt 3D printer could print extremely long objects, far longer than the machine itself.

Alternatively, a belt 3D printer could print an infinite series of smaller objects that would peel off the belt as it turns around, falling into a catch bucket. That is, if you happen to keep feeding the belt 3D printer with filament.

It’s a fascinating concept that a few companies have been exploring, beginning with Blackbelt 3D a few years ago. However, the cost of belt 3D printers has been prohibitive and so they have not really taken off in the market.

But I believe belt 3D printers will become popular.

Low-Cost Belt 3D Printing

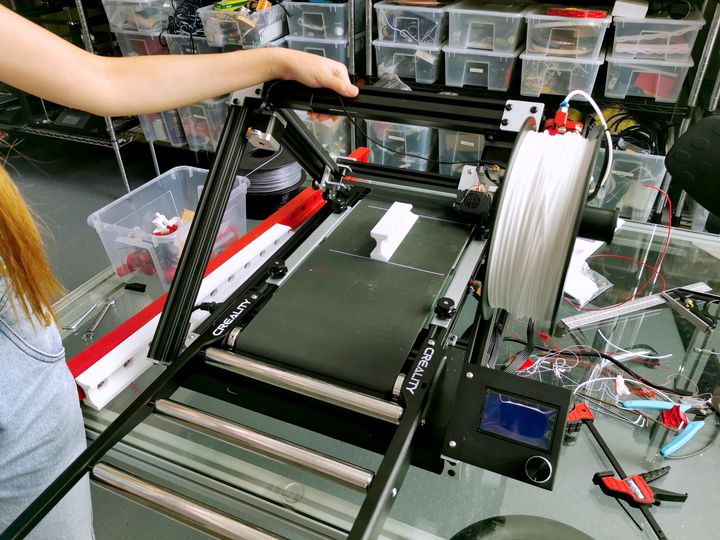

But that is set to change as low-cost 3D printer manufacturer Creality is close to releasing the CR-30 (a.k.a. 3DPrintMill), a true low-cost belt 3D printer.

The CR-30 is apparently not intended to be a “cheap” machine. From a discussion with supermaker Naomi Wu, who is collaborating with Creality on the project, the CR-30 is to be a “workhorse”, ready to 3D print for long periods.

Wu believes the machine could be used by small-time manufacturers to produce low volumes of parts, perhaps for Etsy-like operations.

This concept makes a lot of sense, as the scale of such maker operations would match the production rates on machines of this type. Remember, a belt 3D printer can literally run 24 hours a day producing objects with little or no human intervention required.

One could debate whether Creality could produce a sufficiently robust machine at a low price, but regardless of their outcome the cat is already out of the bag, as the design is open source. No doubt others will attempt to build increasingly robust and powerful belt 3D printers based on this design.

Scalable Garage 3D Printing

During the discussion with Wu I realized that there is a scalability factor that might be in play here when this machine and others like it become popular. It seems the economics of belt 3D printing are quite attractive.

Let’s say an Etsy maker has created a popular item that is producible on a belt 3D printer, and they set up a kind of production line in their garage or workshop. Presumably this could be a profitable enterprise, as each object produced is turned into revenue.

Eventually, if the item is sufficiently popular, the maker may decide to add a second belt 3D printer to the production line. This increases the volume of products that can be sold by a factor of two.

Effectively the first belt 3D printer was able to pay for the second belt 3D printer.

But wait: if the first printer paid for the second, then wouldn’t the first and second printers pay for the third and fourth printers, too? This would certainly be the case if the item were sufficiently popular.

But there’s another twist. With this production capability, the maker could design additional products that could be produced with that capacity.

It seems to me that someone with sufficient creativity and a belt 3D printer could very quickly scale up to a medium-sized production level using belt 3D printers. This is because this style of 3D printer requires hardly any human labor to operate.

I’m certain this type of user will begin to appear once robust, low-cost belt 3D printers hit the market. They’ll drive sales of 3D printers and especially more sales of 3D printer filament material.

Scalable Garage 3D Printing is coming.