This week’s selection is “Mechanical Behavior of Materials” by Norman Dowling, Stephen Kampe, and Milo Kral.

Ever since the introduction of proper engineering materials to the 3D printing world, there has been an increased emphasis on part quality and strength.

In the early days of 3D printing, the materials available at the time were so weak it meant any 3D print was suitable only for form and fit testing, rather than using the part in its intended application. That changed when more advanced materials became possible to 3D print.

But what does it mean for a part to be strong?

This is usually investigated through a series of engineering tests on sample parts, sometimes referred to as “coupons”.

There are different types of tests because there are many different ways a part can fail, and that’s what this book is all about.

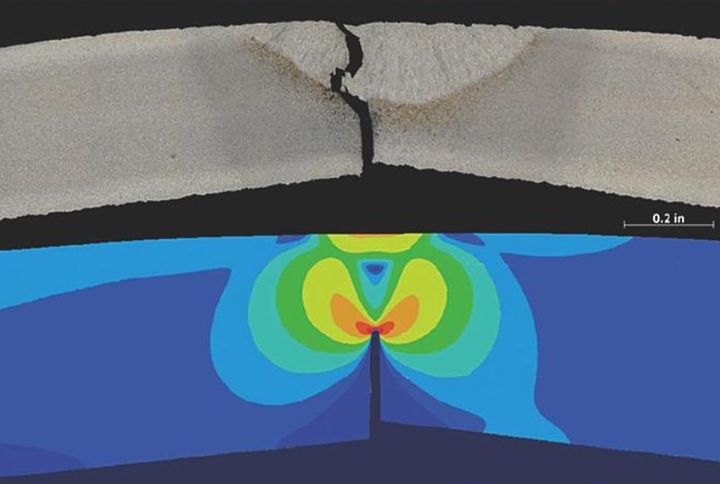

The book begins with a discussion of the different types of failures that may occur in engineering samples. They explain how these occur based on the molecular structure in crystallized materials. Fractures, deformations and defects are all explained.

Different types of testing setups are explored to investigate the various failure modes. For example, they introduce the “tension test” that measures the tensile strength of an object.

Additional tests are described in some detail, including compression tests, hardness tests, impact tests, bending tests, torsion tests and more.

The book then discusses different models for these material behaviors, specifically elastic deformation and anisotropic properties in materials. Mechanical stress and strain are reviewed in an entire chapter.

Complex failure modes are discussed, wherein several different factors are combined, as is usually the case in real-life situations.

Fracture vs. fatigue is the topic of two chapters, where the relationship between the two is investigated. Fatigue cracks, for example, can grow, and ways are shown to estimate how this will occur.

There’s plenty more in this near-1000 page book, which details practically everything you could possibly want to know about mechanical failures.

We’re an Amazon Associate and earn a small fee from qualifying purchases. Help support our 3D print news service by checking out this book!

Via Amazon