High-throughput 3D printing startup Azul 3D has announced an “exclusive development collaboration” with DuPont Electronics & Imaging.

The partnership is set to bring DuPont’s expertise together with HARP (high-area rapid printing) technology with a focus squarely on electronic materials.

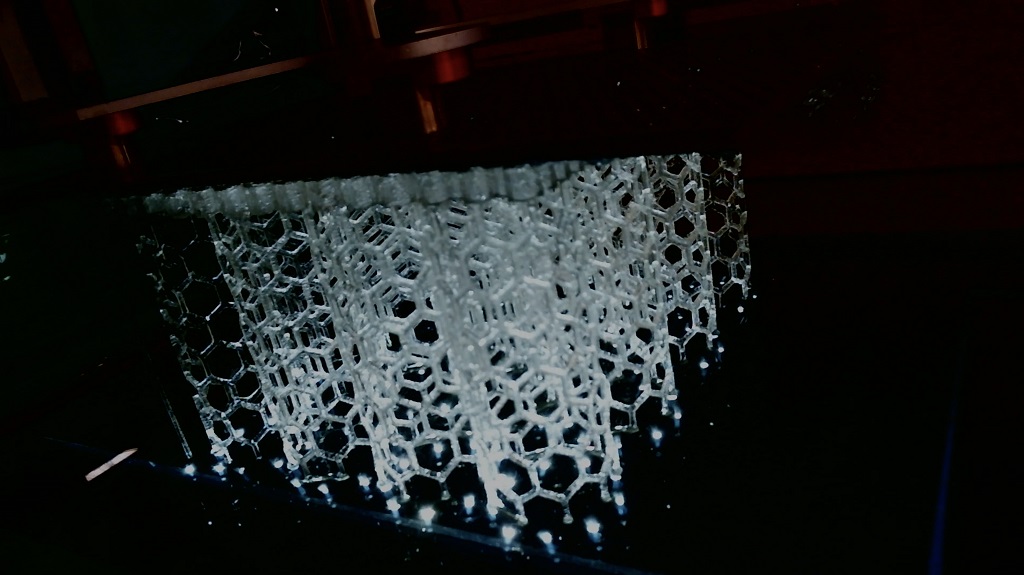

Azul 3D

HARP was introduced last year as a breakthrough from researchers at Northwestern University. As part of its October 2019 introduction, Northwestern explained:

“Often, the pursuit of larger parts has come at the cost of speed, throughput and resolution. With HARP technology, this compromise is unnecessary, enabling it to compete with both the resolution and throughput of traditional manufacturing techniques.

The prototype HARP technology is 13-feet tall with a 2.5 square-foot print bed and can print about half a yard in an hour — a record throughput for the 3D printing field. This means it can print single, large parts or many different small parts at once.”

Those capabilities can, of course, have any number of applications. Large-scale, high-throughput 3D printing would be a benefit to many industries. And industry has certainly noticed — just last month Azul 3D closed a $12.5 million funding round.

Shortly after announcing that round, Azul 3D expanded its Board of Directors, bringing in “legendary investor” and former GEICO CIO Louis A. Simpson as well as ExOne CEO and 3D printing industry veteran John Hartner. It’s always good to bring on more expertise into a Board, but those weren’t the only sorts of major introductions Azul 3D had been positioning.

At the time of the seed funding announcement, Azul 3D Co-Founder and Chair Chad Mikin explained:

“The company intends to secure major partnerships validating this point in the very near future.”

Here we are, just a month later, and one of those major partnerships has formalized.

Azul 3D x DuPont

DuPont is surely a familiar name. The company has wide-reaching divisions into a number of business areas.

They’ve also been involved in the 3D printing industry for some years now, introducing new polymer materials based on their “blockbuster” plastic portfolio.

But directly developing additive manufacturing materials is not their only involvement. DuPont Electronics & Imaging describes itself as:

“[A] global supplier of materials and technologies serving the semiconductor, advanced chip packaging, circuit board, electronic and industrial finishing, display, and digital and flexographic printing industries.”

It is this business segment that has signed on to the collaboration with Azul 3D. The intent, they say, is “to bring next-generation 3D printing technologies to the forefront of the electronic materials industry.”

Specifics on what to expect from the collaboration are scarce at this early stage, but Mirkin notes:

“This collaboration with DuPont is very important to us. In addition to validating the industry-enabling capabilities of HARP, it showcases our ability to use it to transform aspects of the manufacturing sector.”

And DuPont Electronics & Imaging’s Business Development Director, Nick Pugliano, adds:

“Combining DuPont’s expertise with Azul 3D’s capabilities in 3D printing will be a powerful pathway for exploring new technology innovations. We’re looking forward to collaborating to meet emerging industry needs.”

For right now, before more details emerge, it’s simply worth noting that this startup and its novel take on DLP 3D printing is indeed signing on with some recognizable names that have been known to make strong steps in this industry.

Via Azul 3D