Purdue University’s College of Pharmacy and Aprecia Pharmaceuticals are partnering to further technology and research in pharmaceutical 3D printing.

The Partnership

Aprecia’s CEO Chris Gilmore explains that:

“Aprecia’s mission is to maximize and expand its 3DP technology platform through global partnerships that will provide pharmaceutical solutions for unmet patient needs. Purdue University is an esteemed institution, and we are confident that this partnership will advance our future in 3DP pharmaceutical research and development.”

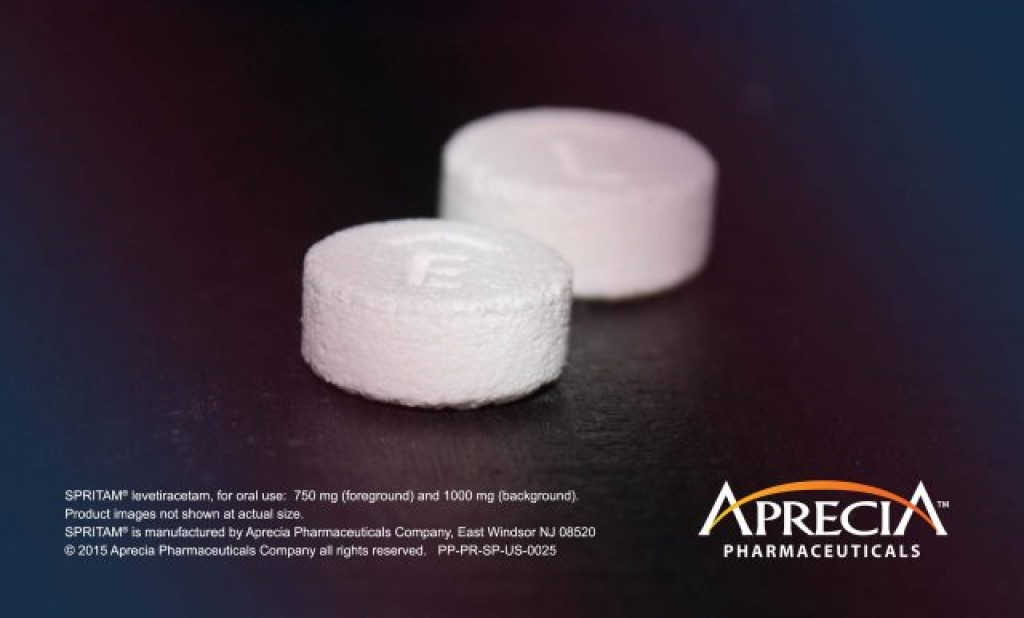

Aprecia was the first to receive FDA approval for 3D printed medication in 2015. On Purdue’s end, Eric Barker, Dean of Purdue’s College of Pharmacy, states that the agreement will allow for interaction between faculty and research scholars, provide access to highly educated students, and guarantee joint collaborations in research and discovery, learning, and teaching, engagement, and technical assistance. He explains:

“Purdue University is committed to its investment in drug discovery and development as well as student and faculty enrichment that will continue to yield global advancement in medicine and health care.

As a college, our mission is to prepare the next generation of leaders in pharmacy. Partnering with Aprecia aligns perfectly with that mission. We are excited to combine our talented students and faculty with the successful researchers at Aprecia to work together to accelerate discoveries in this emerging field.”

Eric Munson, head of the college’s Department of Industrial and Physical Pharmacy, believes that the collaboration will pave the path for the development of complex and advanced medications. He says:

“Giving our faculty and students access to 3DP technology through research projects, internships, and joint collaborations advances our mission of educating and training students through scientific discovery and development.”

The Impacts

Is all this optimism well placed?

The impact of 3D printing in the medical industry has been immense. Combining 3D printing technologies with traditional drug manufacturing methods has many advantages. For example, we can produce complex and difficult medications in bulk, but we can also do the opposite. The ability to design cost-effective custom medications to lessen adverse effects isn’t far away. With COVID-19, this has the potential to go a step further as well.

This type of partnership could help resize and personalize dosages as well. Often times, children aren’t able to take a drug that’s a better fit for them, because they cannot take such high dosages. 3D printing has the ability to produce the appropriate dosages of practically any applicable medication (for both children and adults).

The fact that testing centers are turning people away means that we are testing people that may not have COVID-19, while turning away others who may. Partnerships between the broader medical industry and 3D printing industry could put an end to this.

With “Big Pharma” being an issue in many countries (where companies overprice drugs drastically), customers — or, more likely, compounders — could invest once in a 3D printer and be able to print the needed drugs with their preferred dose, color, and flavor for just a fraction of the price — this could hugely restructure the entire pharmaceutical industry.

Via Pharmacist.com