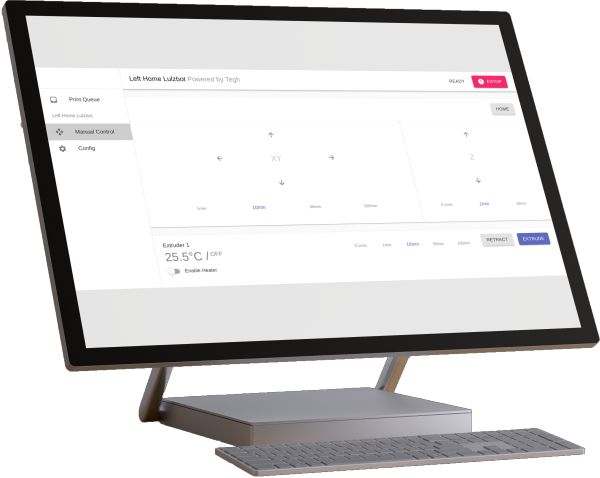

I found what appears to be a new 3D print utility in the making: Teg.

There’s definitely not a lot of information about Teg, as conveyed via their website. However, they do say:

”Teg is designed from the ground up to streamline your WiFi 3D printing experience. Re-imagining the 3D printer workflow to remove print management obstacles so you can worry less and create more.”

Teg appears to take advantage of the ability of many desktop 3D printers to be controlled via their USB / WiFi ports. This capability has been leveraged by OctoPrint, AstroPrint and others, which generally use a set-top box to drive the devices. It seems that Teg will be a Raspberry Pi app.

Teg will apparently work with multiple 3D printers, presumably if they all can participate on a WiFi network. This alone could be a significant advance, as it may be you don’t require a set-top box for each device.

The purpose of Teg at first seems to be for job queuing: you can manage a queue of prints and manually release them when the printer is clear. That’s a minor problem encountered only by those who print a great deal of objects. If you are literally running your devices 24 hours a day, then it makes sense to prep a job queue.

The 3D printer operator would then simply click to release the next job, once the first job’s print plate is cleared and made ready for the next job. That’s a lot faster than opening up a computer and looking around for the most appropriate file to print next, especially if it’s the middle of the night.

But that function seems to be not the main focus of Teg. Instead, it appears to be heading towards the management of job queuing for continuous build systems. They say:

“In Automatic Printing mode Teg will automatically start, stop and remove each print from your queue for you.

If you have the hardware to support automatically ejecting prints all you have to do is add your designs to the queue and Teg will automatically print piles of parts for you.”

That’s a relatively rare feature on 3D printers today, being exclusive to the few belt 3D printers on the market and a couple of machines like the Tiertime X5, which uses a set of print plates for near-continuous use.

There have also been some continuous 3D printers that have gone off the market, the first being the highly experimental MakerBot Automated Build Platform, which I tested in 2010.

Another 3D printer manufacturer, Turkey-based Loop3D, began with a unique continuous printing system involving thin rods in the print plate that would push prints loose. However, by 2019 the company had abandoned that approach completely and instead manufactures the high-end professional Loop Pro 3D printer.

Why did they switch strategies? At the time, I wrote this:

“It seems they received considerable feedback from customers and prospects, and it turned out that few wanted to pay the extra cost required to implement continuous 3D printing, suggesting that they could easily hire manual labor to perform that work instead. In addition, the feedback suggested clients would rather just buy more machines with the savings.”

But could it be that continuous 3D printers lacked suitable software to properly and easily manage a continuous flow of print jobs? Perhaps that is the real target of Teg.

Print ejection is always a straightforward GCODE sequence that could easily be added in by a utility like Teg, and so I can see how they could structure the software to transform an otherwise standalone set of GCODE jobs into a continuous stream of 3D print work.

This might be quite spectacular to watch in operation if deployed on an array of continuous 3D printers.

As of now, Teg does not appear to be ready. However, the site does offer the opportunity to sign up for notice when they are ready.

Via Teg