Charles R. Goulding and Preeti Sulibhavi consider the rising availability and practicality of formal higher education in additive manufacturing.

Higher education has been a cornerstone of the American Dream. Higher wages, increased social mobility, and an overall higher standard for quality of life have been attributed to higher education. The numbers support this assertion as well. College graduates with a bachelor’s degree typically earn 66% more than those with only a high school diploma and are far less likely to face unemployment. In 2015, a study sanctioned by the US Department of Education concluded that by this time, in 2020, an estimated two-thirds of job openings would require post-secondary education and/or training.

But with any great achievement come obstacles. College has never been more expensive than it is right now. Over the past three decades, tuition at four-year colleges has more than doubled, even after adjusting for inflation. Without scholarships, grants, or financial aid, many struggling families face the difficult decision between sending their children to college and keeping their homes.

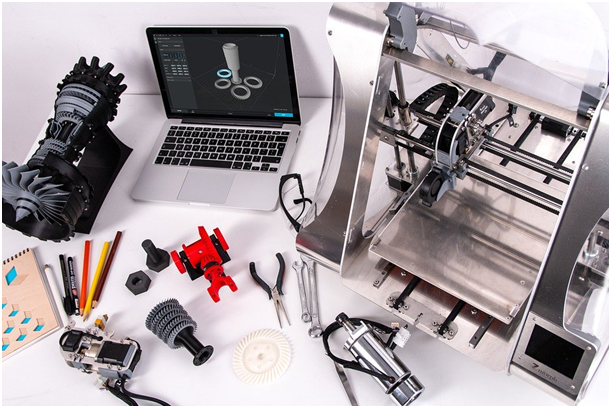

So where does 3D printing / additive manufacturing fit into all of this? One of the criticisms of higher education is that depending on what you major in, a lot of the skills attained at college are often not readily marketable in the real world. Additive manufacturing and 3D printing are skills that are not only readily marketable but transformative. Going to college and getting an education in additive manufacturing can not only add value to students’ degrees but can help students add value to whatever industries they join. The Deloitte Insights Newsletter put the spotlight on 3D printing programs offered by institutions of higher education to prepare the next generation of additive manufacturing professionals.

Here is a shortlist of 10 colleges that offer some sort of degree or courses in 3D printing or additive manufacturing:

| College | Degree |

| Pennsylvania State University (PENN State) | Master of Science and Master of Engineering, Additive Manufacturing & Design |

| Case Western Reserve University | The Sears think[box] Innovation & Entrepreneurship Center is a beacon of AM innovation at the University. It offers a complete ecosystem for venture creation (i.e. design to prototyping and fabrication). |

| Milwaukee School of Engineering (MSOE) | Consortium that includes a suite of AM technologies. Applying AM projects across multiple disciplines, students run the operations |

| Calhoun Community College | This Alabama community college offers a two-year associate degree in AM. Industry partnerships contribute to Calhoun’s 90% success rate of AM students hired prior to graduation |

| University of Connecticut (UConn) | Pratt & Whitney Additive Manufacturing Center (PW AMC) has been the gateway to research resources available to the UConn community. |

| University of Massachusetts – UMass – Lowell | As part of its electrical and computer engineering graduate certificates, students can take an AM in Radio Frequency (RF) & Microwave (MW) Applications course |

| Carnegie Melon | Offering a Masters Degree in Additive Manufacturing, MS in AM, this University’s College of Engineering is helping to define the future of AM. |

| Rice University | In 2019 the Additive Manufacturing, Performance & Tribology (AMPT) Center was inaugurated. Research objectives were shared and technical sessions were offered. |

| New Jersey Institute of Technology (NJIT) | The Additive Manufacturing Lab or AddLab at NJIT specializes in modern AM techniques. Working to make AM a reality, AddLab members collaborate with US Army Armament Research, Development and Engineering Center (ARDEC). |

| Massachusetts Institute of Technology (MIT) | This legendary institution of higher education offers a comprehensive course in additive manufacturing for innovative design and production. It covers business implications as well. |

The Research and Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Lessons Learned

The Deloitte Insights Newsletter’s spotlight on 3D printing has put the additive manufacturing industry front and center. What we need to focus on is how to educate a broader workforce in 3D printing technologies. This can solve the issue of college teaching applicable or marketable skills to students and expand the scale and capabilities of additive manufacturing to transform products and processes in various industries.