Benchmarking samples are often produced to ensure a 3D printed part delivers the required engineering performance. However, miniFactory has introduced a new twist on the process.

For industrial operations seeking to acquire a 3D printer, part of the usual process was to request a sample part produced on the target machine. The requestor could examine the part and gain some insight into the qualities of the device they were considering acquiring.

Thus for many years we’ve all seen advertising from 3D printer manufacturers offering a “Free part” made on their systems to potential clients. Usually this required only the exchange of contact information to complete. This process worked reasonably well, as prospects could examine the benchmark part in hand directly.

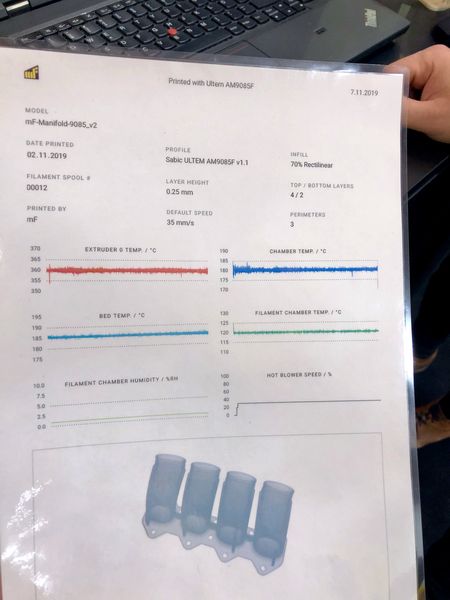

Now Finnish company miniFactory has introduced a bit of a twist on this process. You can certainly request a part, but along with the 3D printed sample will come a detailed engineering report.

The report is generated by miniFactory’s unique Aarni system, in which detailed information about each print is reported. This information includes basic “tombstone” information, like time and date of production, but also details collected from sensors in the machine during the actual production of that part. The Aarni report contents includes a record of temperatures, humidity and other information that helps validate that the part was indeed produced under optimal conditions.

I’m thinking this approach could upset the practice of issuing sample 3D prints by 3D printer manufacturers. Imagine the following scenario.

You’re a potential buyer of a 3D printer, and you’ve obtained the specification sheets and pricing for several purchase options. You also have requested a sample part from each vendor, and they’re sitting on a desk in front of you.

One of the samples (from miniFactory) is placed on the printed Aarni report. The other samples sit alone, with zero documentation on their production.

What’s going through the buyer’s mind at that point? How do the other samples appear next to one that has a printed pedigree? Were the other samples printed with consistent temperatures during the entire print? Who knows?

How could this influence the buying decision?

I think this approach could add a great deal of confidence in the miniFactory solution, and thus could lead to an increase in their sales.

After all, transparency is always a good thing and the Aarni report is all about transparency. This is a very intriguing way to leverage the Aarni report, a feature I don’t believe other 3D printer manufacturers have.

That may change, however, as the Aarni concept is compelling. Other 3D printer manufacturers might begin producing similar reports for their 3D prints. At some point this type of reporting might become an expected part of the 3D printing process.

But it’s not yet today.

Via miniFactory