3D printing funding is looking down in the mouth today as LightForce Orthodontics announces a $14 million Series B round.

In general, when we talk about 3D printing in orthodontia we’re thinking about the increasingly-ubiquitous clear plastic aligner. This sort of aligner, from the likes of leading companies like Invisalign and SmileDirectClub, uses 3D printing technology to create completely personalized clear devices worn over the teeth to help straighten them. But the aligners themselves aren’t 3D printed, the molds are. These devices are also generally targeted at adults and others who need “just a little help” straightening their teeth, not for adolescents or those needing significant orthodontic work for that perfect smile. There’s also, of course, the issue of compliance; for aligners to work, someone actually has to wear them as prescribed.

So it’s something very different we’re seeing today from LightForce.

3D Printed Braces Brackets

If you’ve had braces, you know the unique pains of the bracket-and-wire setup that seems to many a teenage mind more a torture device than an investment in their future smile. I had braces twice in my youth, thanks to some weird toothiness, and can’t say I had any love for the experience. Some of it was from the actual wear, sure, but a lot was also just experiential: frequent trips to the orthodontist to tweak and tighten the off-the-shelf mouth gear.

As it turns out, like in so many other areas, orthodontia becomes much more palatable (pun intended) when it’s personalized.

Enter 3D printing.

LightForce Orthodontics produces to date what they claim to be (and seems to be) “the world’s first and only fully customizable 3D-printed bracket system.”

I spoke with LightForce CEO and Co-Founder Dr. Alfred Griffin III, DMD, PhD, MMSc — more on that conversation in this Forbes piece — to learn more about why 3D printed brackets would serve braces wearers (and providers) better than the current one-size-fits-all bracket approach. Why, I asked, use 3D printing here?

“It makes a lot of sense — for any 3D printing application, you need to check at least one of three boxes: value of customization, part complexity, and people willing to pay for it. We’re lucky in orthodontics space we check all three of those boxes. We’re in an industry with a value of both part complexity and customization. Every part is as unique as a fingerprint or, more accurately, as unique as a tooth,” Griffin explained.

“Look at the 3D printing industry in general, I would say that the biggest win for the industry has been Invisalign. Automotive has seen some big wins, and so have some other industries, but Invisalign is doing $2 billion in revenue. That adoption was 20 years ago. Why is it such a success? This industry really values customization more than any other industry.”

As a backgrounder, he added, the braces kids get today are technologically the same as those their parents, and even grandparents, got. “Not much has changed,” he said, as brackets are injection molded and then get bonded onto the teeth.

Everyone’s teeth, though, aren’t the same. And nor are everyone’s orthodontic needs. Aligners aren’t the best fit for cases requiring a full set of corrective braces because there’s much more to a perfect smile than straight teeth.

“A lot of direct-to-consumer orthodontics have the bar set at straight teeth. That’s not the bar for us, or for most orthodontists. You’re looking at the smile arc with how much tooth is showing, you’re looking at the bite in the back, if that’s healthy — it’s a lot more than just straight teeth,” Griffin explained. “This is important because everyone’s jaw is different, their lip position, their gums, it’s all unique. It makes zero sense to treat that with a one-size-fits-all bracket.”

This application fits well with the promises of 3D printing, as well, for another real-world major use case that could effect real change in a major industry.

“We’re talking serial production of 3D printed parts. It’s something that is talked about in theory quite often, like at business schools and engineering schools, but real digital manufacturing still is not really happening in the real world,” Griffin said pragmatically.

So LightForce is 3D printing individualized brackets. On top of just fitting a patient better, these brackets “significantly reduce the number of adjustment visits needed” — which is also a major benefit specifically in 2020, when people don’t want to be going to more visits anywhere than is needed (particularly when those visits involve a lot of open-mouth time that could increase the risk of transmitting droplet-borne viruses).

Griffin wouldn’t go much into the proprietary technologies LightForce is using in its ceramic 3D printing endeavors. Today’s funding announcement explains some of the workflow, though:

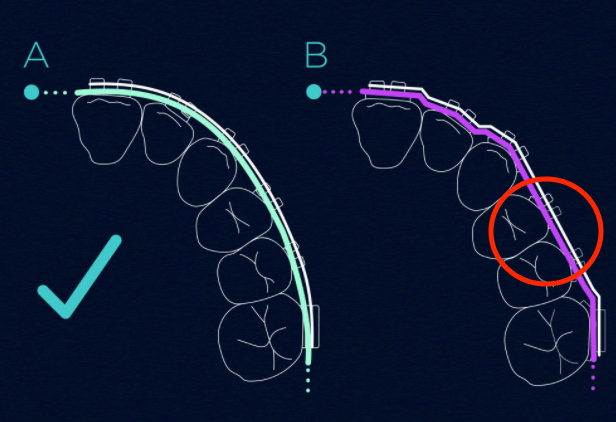

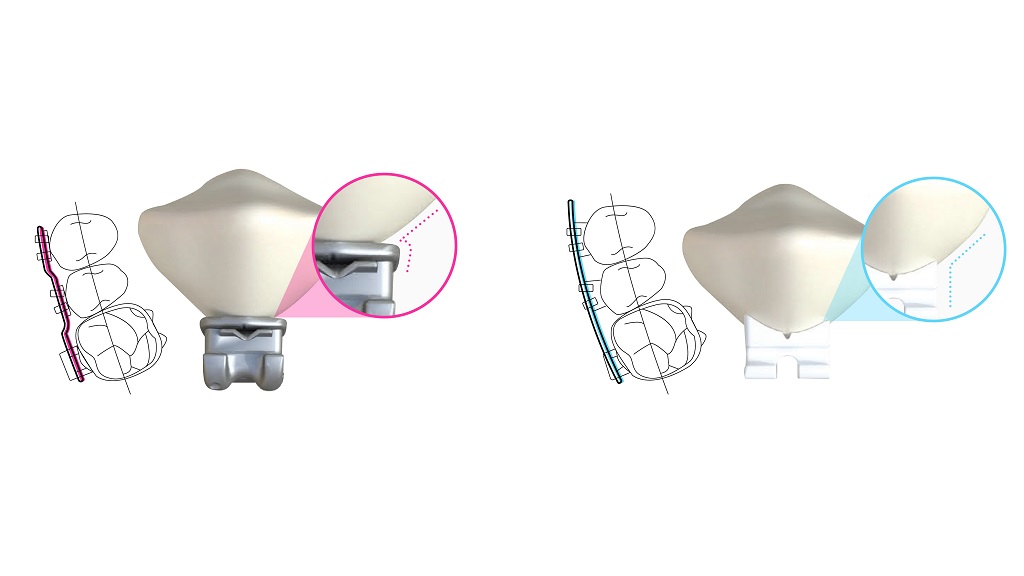

“Orthodontists who treat patients with LightForce technology begin the process by sending LightForce technicians a scan and requirements of the patient’s teeth. The LightForce team then creates the fully-customized brackets and trays and sends it directly to the practice for the orthodontist to bond to the patient’s teeth. LightForce technology uses ceramic material virtually identical to familiar injection molded brackets, but is specially formulated for 3D-printing. The technology elevates the standard for precision and strength for today’s orthodontic appliances, while also offering patients a new esthetic option.”

LightForce Series B

The prospect is interesting — and that interest is investment-worthy, as we come back to the financial side of this all.

LightForce Orthodontics has closed a $14 million Series B funding round, with investment led by Tyche Partners and follow-on investment from Matrix Partners and AM Ventures.

The funding comes at a strong time for the company; Griffin noted in the announcement that LightForce has “seen our business double every quarter.”

“We’re always looking for visionary entrepreneurs utilizing the latest cutting-edge technologies to transform and revolutionize industries,” said Weiji Yun, Managing Partner at Tyche Partners. “Alfred and [Co-Founder Dr. Lou Shuman, DMD, CAG]’s inspirational vision offered us an opportunity to expand our 3D-printing investment portfolio and the company’s rapid growth is proof that the industry is primed for a solution that improves the orthodontic experience for patients and doctors alike. We are pleased to partner with such an impressive team of doctors and engineers and contribute to LightForce’s success.”

The company currently offers a treatment platform they describe as including:

- LightPlan (Treatment Software by LightForce): With complete control of every aspect of the treatment plan and a simple cloud-based interface for adjustments and approvals, the proprietary LightForce software system empowers the clinician every step of the way.

- Cloud Brackets (Braces by LightForce): LightForce’s Cloud brackets are white, patient-specific 3D-printed ceramic polycrystalline alumina brackets.

- LightTray (Indirect Bonding Trays by LightForce): The LightTray is a patient-specific indirect bonding (IDB) tray 3D printed from a proprietary material. This material is the result of seven 3D algorithms unique to LightForce that are all intended to optimize the clinical user experience and bonding accuracy.

- TurboTrays (Bite Turbos by LightForce): LightForce TurboTrays are 3D printed to aid in the patient’s bite correction.

The Series B funds will be used “to further develop its technology and product offerings, as well as to scale operations to meet the recent surge in demand for more efficient dental technologies,” LightForce explains.