SPONSORED CONTENT

When investing in new industrial 3D printing equipment, a common concern is ROI — it turns out that return on investment can be as fast as 90 days.

3D printing offers unique capabilities that can make it the best tool in the toolbox for applications in low-volume manufacturing. Removing the time and expense of making tooling for each individual design is one such benefit. While creating a costly mold for mass production via injection molding makes sense, as every part made is set to be made in large quantities and needs to be the same, even a slight difference in a part would require a new mold. That new mold could cost up to tens of thousands of dollars to create, and could take months to fulfill.

Rather than wait those months, though, low-volume producers are increasingly turning to industrial 3D printers to make dozens to a few thousand parts. The lack of tooling means each of those parts can be slightly (or completely) different. That sounds like a win — but there’s still the initial cost of investing into new production equipment.

TrySight 3D Printing

TrySight is a Canadian assistive technology company, leading the way in hardware and software solutions for the visually impaired. From wearables and handheld magnifiers to screen magnifier software and portable readers, the company serves educational institutions, hospitals, and rehabilitation departments to help those with low vision and blindness.

The assistive technologies TrySight offers place the company into a pretty niche market that requires frequent changes to designs and relatively low production runs. When making 50-1,000 parts that may see changes or require fast iteration to update and validate new concepts, traditional tooling-based production methods are simply uneconomical.

Over the last half-decade, TrySight has turned its sights on bringing 3D printing into play, as the technology is well suited for the type of manufacturing the company needs. Working with FFF 3D printing for five years helped in many ways — but fell short of delivering in every area the team needed.

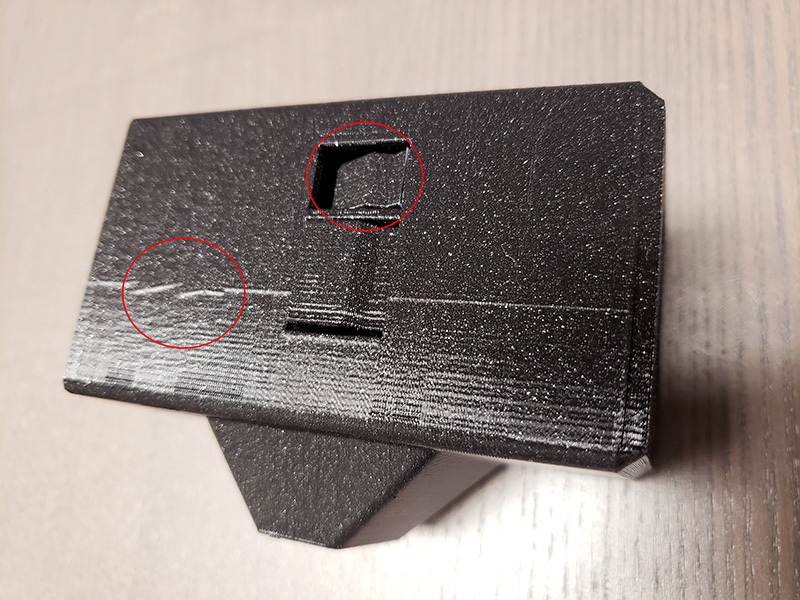

With FFF, TrySight discovered the parts they were 3D printing didn’t meet dimensional tolerances or strength or temperature resistance for end-use parts. Aesthetically, the visible layer lines also held back end-use acceptance. On top of that, they discovered high labor and material costs from support structures, high print failure rates, and constrained build areas.

3D printing was the answer — they just needed to examine another process.

Turning To Industrial SLS

TrySight found that selective laser sintering (SLS) would offer the benefits of 3D printing they needed, without the limitations of extrusion-based systems. Because their previous efforts with FFF had shown a low success rate for high-value institutional contracts, the team wanted to take their time in understanding and comparing essentially all SLS solutions on the market.

Following six months of analysis and weighing all their options, TrySight invested in a MfgPro230 xS system from XYZprinting. They found that it would deliver the quality it needed in the right compact footprint, and at the price-to-performance ratio that they wanted, all with an open materials ecosystem that meant they would be able to work with the best-fit materials at any given time without being limited to just a few selections.

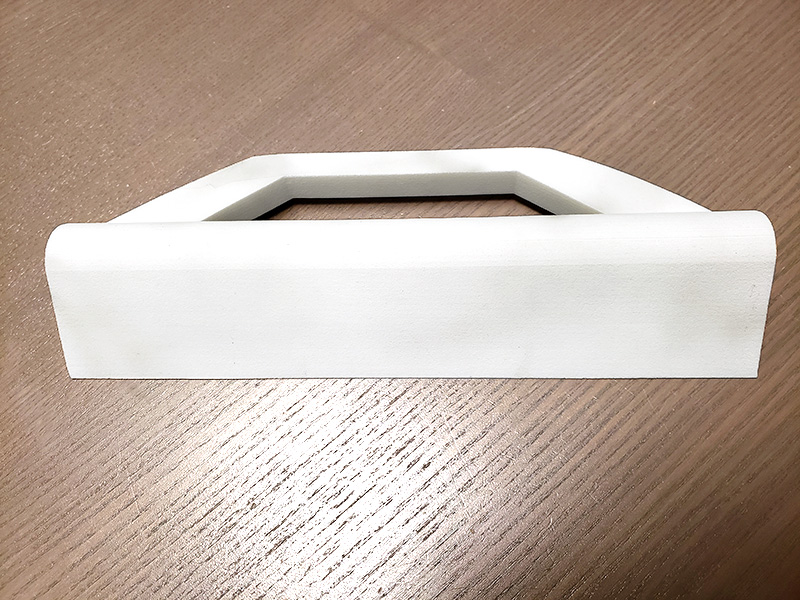

TrySight put its new MfgPro230 xS to use quickly, using sPro12w material, and started 3D printing new designs. Without the need for support structures or constraints of a small print bed, the company found new freedoms of design — and the ability to manufacture dozens of parts per day with three-dimensionally packed parts in the powder-based system, cutting labor costs.

The parts that came off the new system checked every box for TrySight, performing to their standards in terms of tensile strength, temperature resistance, surface finish, and overall quality. The same system can be used for both prototyping and production, reducing the pathway to end parts and speeding up the move toward production into hours instead of weeks.

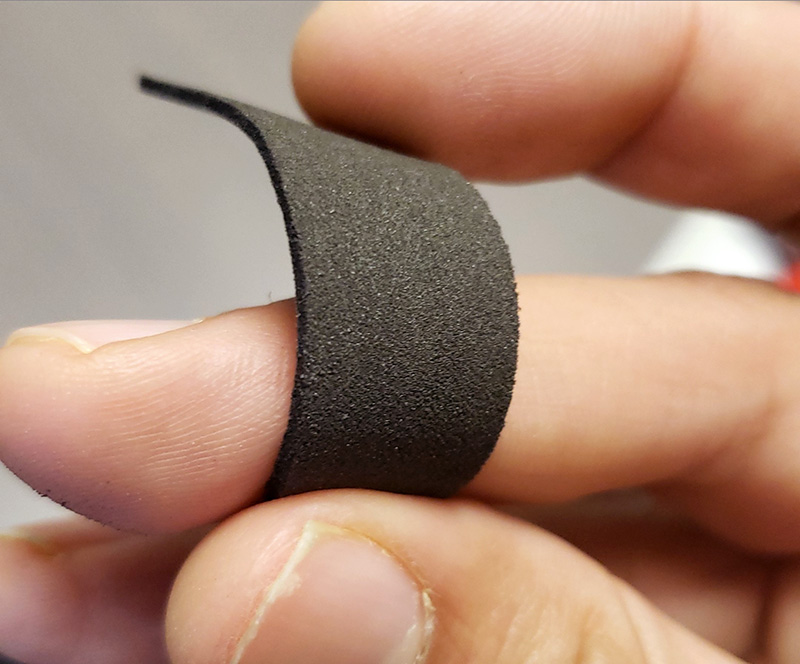

In addition to sPro12w, TrySight has also been experimenting with third party flexible materials, like TPU, to create custom-fit wearables. The flexibility of manufacturing, from design to materials to workflow, has already boosted the company’s bottom line.

So helpful indeed was the adoption of the MfgPro230 xS that TrySight found a remarkably fast return on investment:

“The MfgPro230 xS is the first industrial quality SLS printer at a sub-industrial price point. It paid for itself in the first 3 months,” said Umang Dua, President of TrySight.

TrySight is looking ahead with its new SLS 3D printing capabilities. With the system already achieving ROI, the company is looking toward a profitable future in production. The future is bright for TrySight with its SLS capabilities, as they continue to 3D print bespoke parts in a variety of materials.

Via XYZprinting and TrySight