I heard about a new 3D printer filament with an unlikely combination of materials: PLA and ABS.

ABS and PLA are the original materials used for FFF 3D printing, and while PLA has remained quite popular, ABS has been rivaled by other easier-to-handle materials like PETG.

ABS was valued because it has a relatively high heat resistance, as compared to PLA, and is a bit less brittle. This allows it to survive longer in mechanically challenging applications. However, it has two unfortunate properties that have limited its use.

First, ABS has a tendency to warp when 3D printed. It’s often challenging to 3D print ABS in anything other than a heated enclosure, which is a rare feature on desktop 3D printer equipment.

Secondly, ABS emits a foul odor when heated. This “plastic smell” is not at all pleasant, and supposedly is not notably harmful to humans. However, myself and many others would simply prefer to avoid any doubt by not using ABS.

On the other hand, PLA is almost warp-free, at least in the relatively small 3D prints usually produced with it. PLA also emits an odor, but it is usually a somewhat pleasant “sweet” aroma that passers-by will notice.

Any odor is probably bad because the smell indicates the presence of nanoparticles, but at least PLA’s odor is “nice”. The best practice here is to ventilate away any emissions.

PLA-F Properties

So we come to PLA-F, which is apparently a blend of the two. This piqued my curiosity, as the properties of such an unusual combination could be good… or bad.

Would the material have high heat resistance and no warping? Or would it have the opposite? Would it smell when printing?

I intended to find out.

I ordered a spool of this stuff from Sandoz, a Canadian reseller that appears to be the only Western source of PLA-F. The material seems to be produced by Sunhokey Electronics Co., Ltd. in China, from which Sandoz likely gets their product. [UPDATE: The PLA-F in question was NOT manufactured by Sunhokey, they may be just another reseller.]

It’s sold in 1kg spools in the usual 1.75mm diameter format and comes in ten typical colors. I chose gray, as I was not feeling particularly extroverty at the time I ordered.

In appearance, PLA-F looks much like PLA or ABS; I couldn’t tell the difference visually. Any tactile difference was not apparent, either. It seems to have a little less brittleness than PLA, however, when you attempt to bend the filament.

PLA-F Temperature

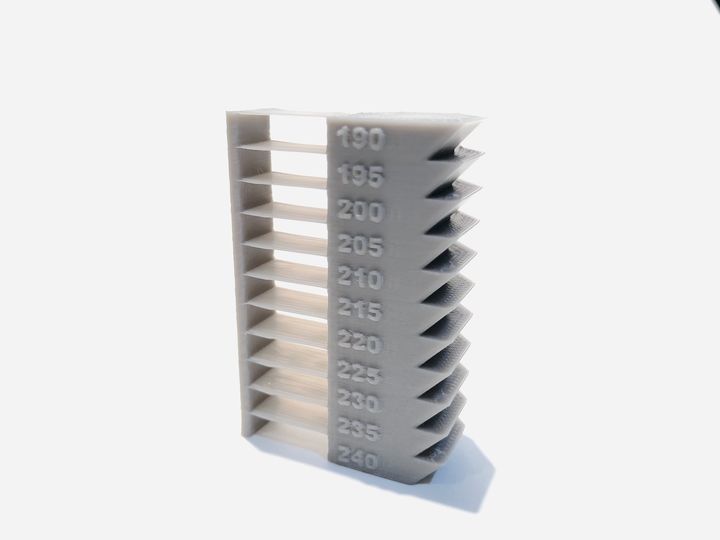

The instructions say to 3D print this material at 230-240C, which seemed appropriate, given the type of materials present. However, just to be sure I 3D printed a temperature tower to gauge the optimal temperature. The results were rather strange.

As you can see, there was virtually no difference in results in almost any temperature attempted on this tower from 190-240C. Even the bridging worked well, and that’s usually the first sign of temperature issues.

In a way, that’s actually a good thing: the operating temperature range of this material is wide, so it’s harder to get into trouble if hot end temps wiggle.

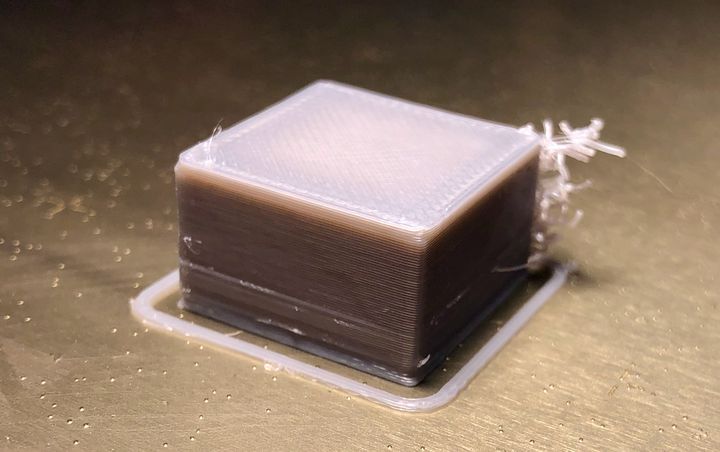

I then 3D printed the ubiquitous 20mm cube to see how PLA-F worked on a basic model. The cube come out well, except for some very unusual stringing on one corner. I’d never seen this before, so I 3D printed a number of additional samples. Eventually I realized what was happening: I was using Octolapse to capture a time-lapse video of the print, and at each layer the hot end would move to THAT CORNER, evidently pulling a strand of material from the corner. After re-trying without the video, it worked perfectly.

However, in other models I did see this strange, thick stringing. It was very odd, but easily removed after printing.

All my prints came out with excellent quality at the 220C temperature I chose. It might have been possible to eliminate the fat stringers with lower temperatures, but I was already quite a bit below the recommended temperatures.

To test this extruder slop a bit more, I printed a Jun Lester Saplad’s excellent gap tolerance test.

The results, shown here, indicated gaps below 0.15mm were compromised. This seemed reasonable to me given the machine they were being 3D printed on. No concerns from me.

PLA-F Warp Test

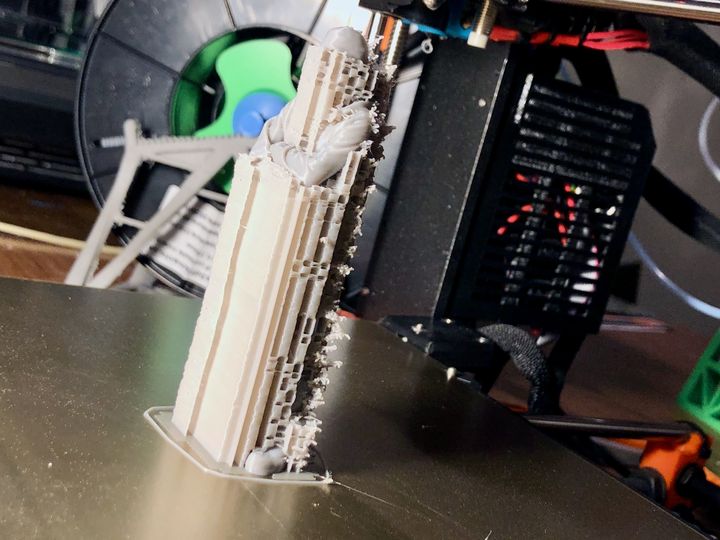

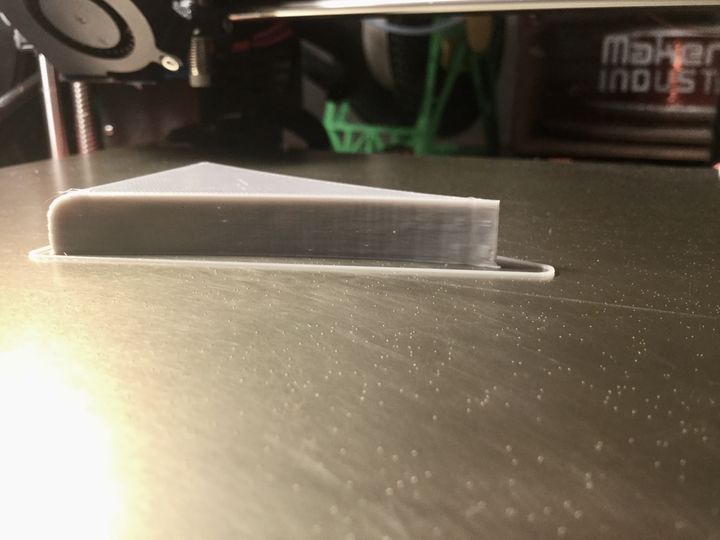

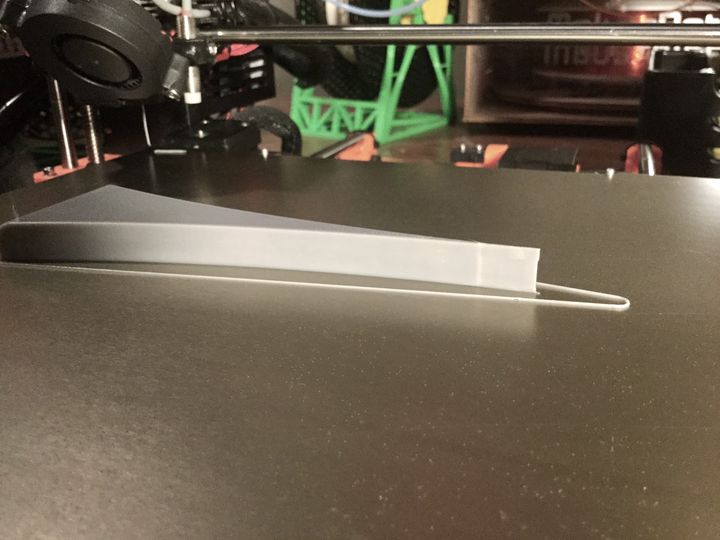

One of the properties I was most interested in seeing was whether PLA-F would warp like ABS. I devised a warp torture test 3D model, one that had a very long and sharp end that would surely warp even regular PLA, let alone ABS.

It printed fine. It did not lift off the bed at all.

Determined to make this fail, I stretched the 3D model much longer to 150mm, with an incredibly thin and sharp end, as you can see here.

Of course, it didn’t warp at all, either.

Evidently PLA-F has some very good non-warp properties. It should be quite useful for pathological models that would otherwise warp with other materials.

PLA-F Smell

I was quite curious about any odor emitted by PLA-F when printing. However, I was surprised to find that it had virtually no smell at all. Not a good nor bad smell, just nothing. That’s probably how all filament should be.

PLA-F Brittleness

To test the brittleness of PLA-F I decided to 3D print a couple of springs. One I made in PLA, and the other in PLA-F.

They both 3D printed quite well, but there was definitely a difference when you attempt to squeeze the springs: the PLA spring pushed back more, indicating more rigidity. The PLA-F sample squished down more easily.

This suggests PLA-F would be usable for applications requiring a bit of “give” or flexibility in the parts.

PLA-F Temperature Resistance

Another property of interest was heat resistance. Would PLA-F sag like PLA, or would it retain strength like ABS when things get hotter? PLA has a glass transition temperature of 60C, whereas ABS is closer to 100C. Which would it be?

To test this property I devised another 3D model specifically to test heat resistance. It was a square block supported by some spindly legs. The idea here was to see when the block’s weight would cause the legs to collapse when softened. Both were printed with identical parameters aside from temperature.

Performing the test was done in a PrintDry filament dryer. This device, which looks suspiciously like a common food dryer, happens to have a temperature control: you can set it to any temperature between 35-70C (verified with another thermometer), and let it sit for hours.

I printed two samples, one in PLA-F and the other in Prusament Galaxy Black PLA. Excitedly, I put them both in the dryer and set the temperature to 60C. I thought the PLA would collapse, while the PLA-F would remain standing.

This did not happen.

After an hour I discovered both 3D prints were flat on the plate. Evidently both were negatively affected by 60C temperatures. I decided to make a more sophisticated test sequence: Start at 40C and go up by 5C each hour, checking for sag.

What resulted was quite surprising. At 50C, this is what I found in the PrintDry:

Yes, the PLA-F had collapsed BEFORE the PLA! The PLA was a bit soft, but not enough to allow the weight to push it down. Unfortunately, the spaghetti-like legs on the PLA-F sample could no longer hold up the block.

Evidently PLA-F has LESS heat resistance than normal PLA and far less than ABS, at least in my test.

PLA-F Conclusion

While PLA-F doesn’t seem to be suitable for higher-temperature applications, it is a very good PLA alternative. It doesn’t warp at all and sticks to a PEI bed quite well. The prints appear quite attractive, at least in the neutral gray color I used.

Sandoz sells this material for CA$23 (US$17.50) in 1kg spools, so that’s a pretty decent deal. The manufacturer seems to sell them for US$7.80 in a minimum quantity of 10 spools, but you may have to pay more for shipping.

I’ll be finding out shortly – I just found a spool of “CAROSE” PLA-F for…$11 shipped. Way too good to pass up. If I get 5 prints from it I’ll be happy.

This page is a great guide to working with this stuff. It’s getting rare, I suspect it’s being outcompeted by PLA+.

you do realise changing the parameters in the openscad just changes the TEXT on the tower, right?

there is an explanation there about how to change the gcode so that the tower works.

That explains the “surprising result”….

Sure do – we always run the same GCODE that includes temperature switches for each level.

your guide to printing the temperature tower does not mention post processing the gcode. if you downloaded his gcode its probably preprocessed, but if you modified the scad, you need to post process the gcode produced. just as a quick check, try to print your tower with temperature in the slicer once 240, once 190