Art and utility come together in the sleek 3D printed Air Management System (AMS) Mini.

Barcelona-based FICEP S3 recently introduced the small appliance to help people breathe easier in enclosed spaces. The company, which previously developed a way to use its 3D printing waste as a sustainable concrete alternative, often uses its technology to create new solutions to existing problems.

UVC Air Management

The issue they faced this time is straightforward: people want to breathe safely.

UVC light has been shown to work as an effective disinfectant for, eliminating transmission of pathogens in the air. Human exposure, though, must be limited, so high-tech UVC solutions are arising to disinfect without exposure. Citing data from the Columbia University Irving Medical Center study regarding the efficacy of UVC rays and highlighting the importance of those ultraviolet rays being far away, FICEP decided to create a UVC-based, 3D printed solution.

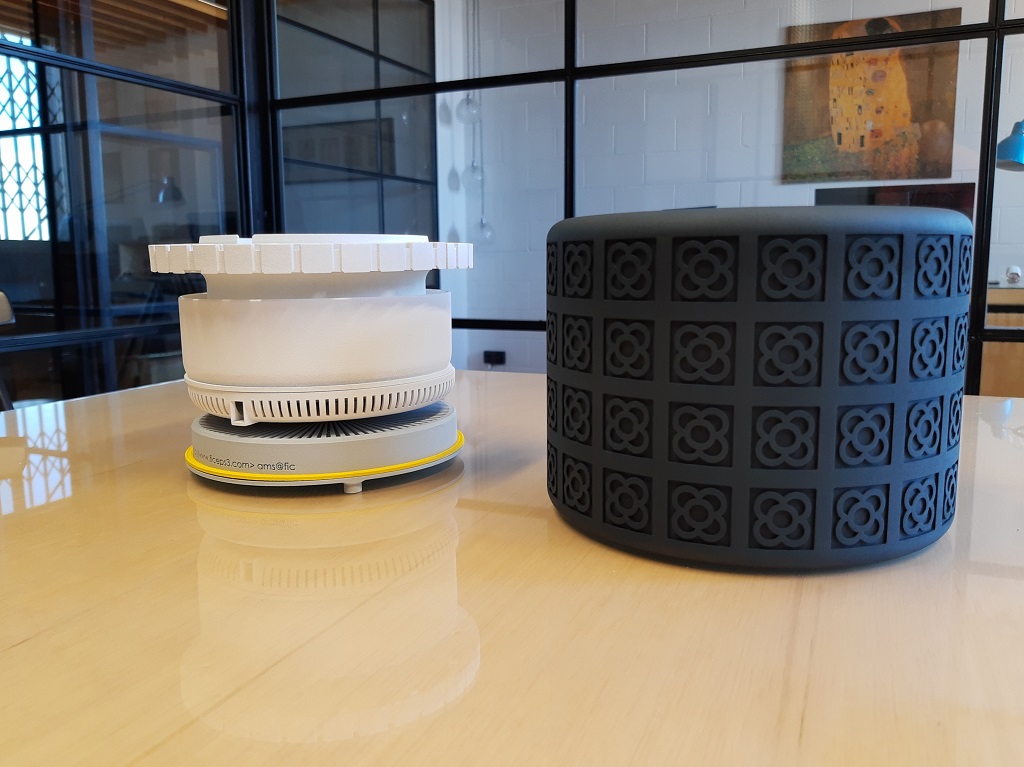

The challenge is that air management systems of the function and power they wanted are “usually found in units the size of a refrigerator.” They wanted to make an AMS with a maximum diameter of just 200mm — compact enough for convenient desktop use, while still housing powerful UVC light to clear the air.

FICEP Co-Founder Nuno Neves designed a Center for the Development of Industrial Technology- (CDTi)-certified AMS several years ago. In light of recent conditions, he worked to miniaturize that device to reduce the number of airborne pathogens with a smaller footprint.

Design of the AMS Mini starting with its core — and Neves was aided in his outward flowing design vision by the geometric complexities possible with 3D printing.

“Additive Manufacturing was crucial in shaping every single part of the AMS Mini. From its cooling channels for the UVC modules, to its buttons, there is not a cubic mm of space that exists without a purpose. Being freed from the restrictions of molds and machining, we were able design without compromise, allowing us to miniaturize several systems and interconnecting them within a limited area without sacrificing efficiency. Using Our HP MultiJet Fusion 3D Printer, we are able to efficiently manufacture two complete units within one build by nesting smaller parts within larger ones, optimizing space,” Neves explains.

The device is currently in its second generation, dubbed the AMS Mini PRO G2.

AMS Mini By The Numbers

The AMS Mini is ultimately completely 3D printed, save for the electronic components. The device was made with:

- Material: PA12 (HP PA12 High Reusability)

- Mix: 80 recycled / 20 fresh

- Mode: Balanced Mode

- Print time (two units): 16 hours

- Cooling Time: 42 hours

- Interior coating: TiO2 (Titanium Dioxide) nano-particles suspended in resin

- Exterior coating: Matt Finish, Synthetic Paint, hand applied.

It can process up to 270m3 of air per hour with an effective coverage of 72m2 of floor space, FICEP says.

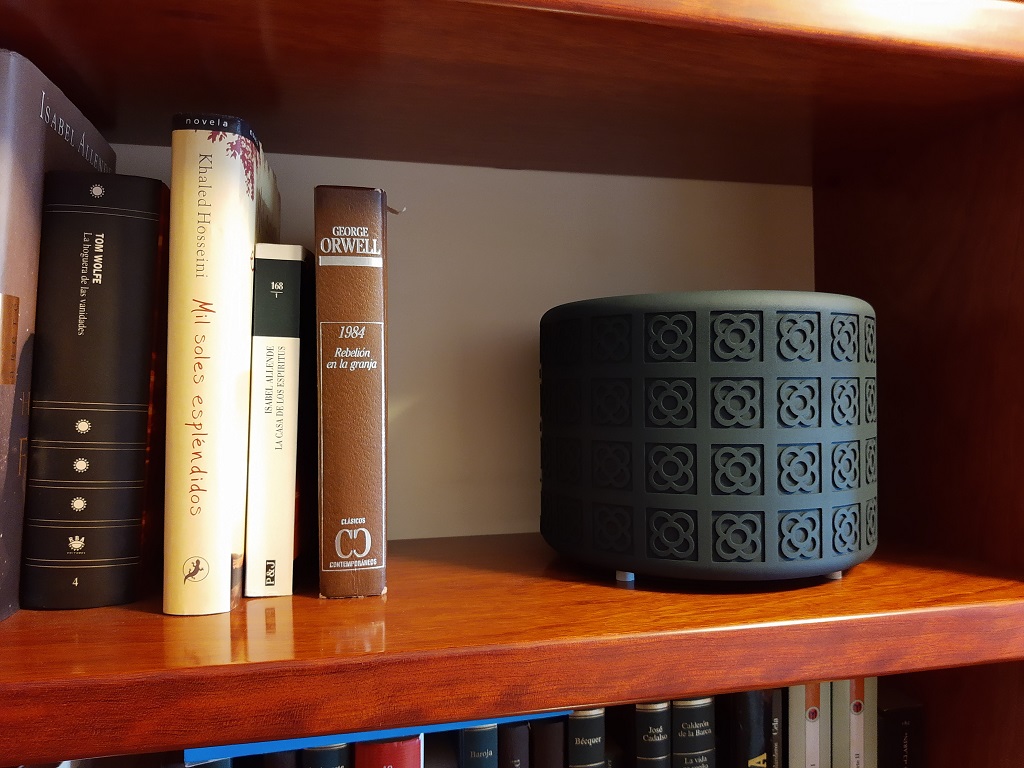

Additionally, because the AMS Mini is 3D printed, the outer casing can be customized. Branding can be included so hotels and restaurants, for example, can display their logo to ensure the little appliance looks like it fits intentionally into its surroundings.

Furthermore, FICEP notes that the AMS Mini offers three levels of protection with “a triple process for air purification”:

- The interchangeable multi-layer filter with activated carbon filters out dust and impurities, as well as safely neutralizing odors with pure activated carbon.

- An exclusive cyclonic labyrinth coated with TiO2 (Titanium Dioxide) nano-particles fixed in resin acts as a catalyst to fuel a photo chemical reaction with the UVC light that helps to decompose harmful Volatile Organic Compounds (VOC), breaking them down, and safely eliminating them from the air. This is a UVC and TiO2 based advanced oxidation process which uses UVC radiation within a spectrum of 320 – 380 nm with a TiO2 nano particle photocatalyst to excite one of the electrons in to the conduction band of the atom, creating a positive opening in the valence band, effectively oxidizing organic compounds.

- 12 High power, medical grade, UVC modules featuring independent control and feedback loops. The UVC modules are protected by specially designed cooling channels which remove heat with pre purified air.

Next Steps For The AMS Mini

Now, FICEP is working to get the device into the world in two interesting ways.

First, in November, the AMS Mini will go on permanent display at the Barcelona Museum of Design (Museu deDiseñy de Barcelona).

“We felt the need to create a medical grade device, that didn’t look like another sterile appliance. To create something for a purpose, while at the same time distracting the end user from that purpose, to calm, to ease the mind, and to be admired,” Neves says of designing a piece for both form and function.

Secondly, the FICEP team is running a campaign on GoFundMe looking to raise funds to make and donate the AMS Mini.

“Given the current global pandemic, and the inability, or unwillingness of public administrations to properly manage this health crisis, the goal of this campaign is to donate AMS Mini PRO G2 units to hospitals, public medical centers, residencies, schools and shelters, in order to protect to the best of our ability the most vulnerable among us, including front line workers such as medical staff, teachers, and volunteers,” the campaign explains.