Australia-based Cultivate3D launched a massive new 3D printer that includes several very unusual features.

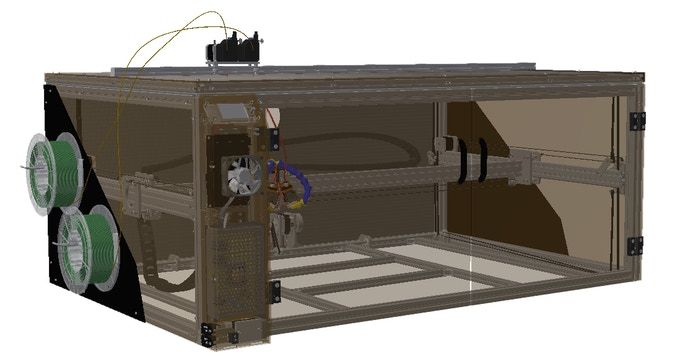

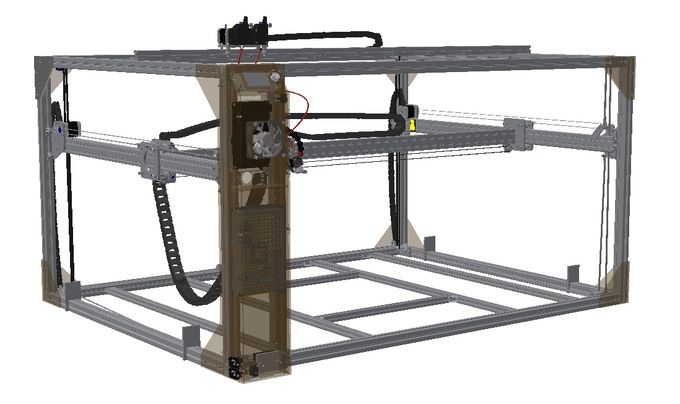

The “Elevator” is a large-format FFF-style 3D printer, and as such it would compete with the other large-format providers such as 3D Platform and BigRep. The Elevator’s build volume is 1000 x 660 x 500 mm, making it one of the largest FFF devices you can purchase, and it turns out the price is surprisingly low. But more about that later.

Cultivate3D has marketed several other 3D printers in the past, and thus the Elevator represents the accumulation of technical knowledge obtained from experience with those products. While the Elevator is designed around a familiar Cartesian motion system, there are quire a few interesting features that I’d like to highlight.

Belt-Driven 3D Printer

The Elevator has no threaded rods for driving the Z-axis, unlike basically every other 3D printer I’ve ever seen. The threaded rod approach involves turning a rod slowly, which causes the build platform to raise or lower. However, there’s a very common problem: imprecise rods.

Threaded rods are often not quite “true”, and thus as the bed moves it can shift ever so slightly one way or another. It’s easy to see on a machine with really bad rods, but its effects can be seen even on “good” machines when printing smooth vertical surfaces.

The Elevator gets around this issue by using belts to drive the Z-axis! This provides a much smoother motion and that carries forward into more accurate and smooth 3D prints.

Medusa Multi-Material System

The Elevator includes an advanced multi-material system Cultivate3D calls “Medusa”. Presumably that’s because it has more than one head?

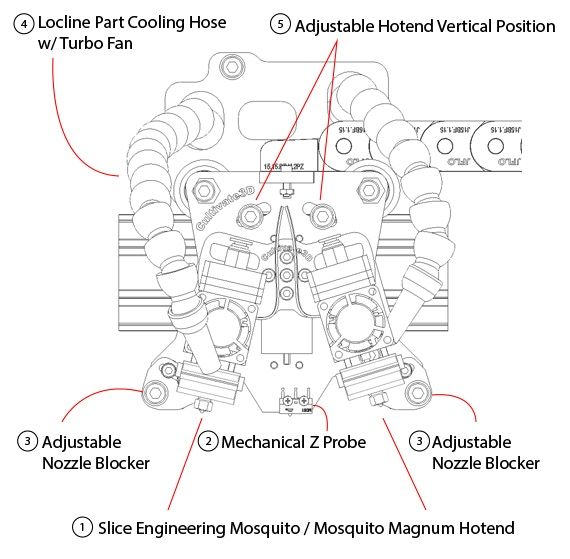

In any case, the Medusa attempts to solve the multi-material problem that has been poorly solved by two common approaches in other machines:

- Dual extruders and hot ends: When one hot end is working, the other is dripping material on the print, or has been cooled down to prevent that — but then must be heated up, slowing the print job tremendously.

- Single hot ends with dual extruders: The single nozzle solution avoids drips, but requires flushing the hot end whenever the material changes, resulting in tremendous filament waste.

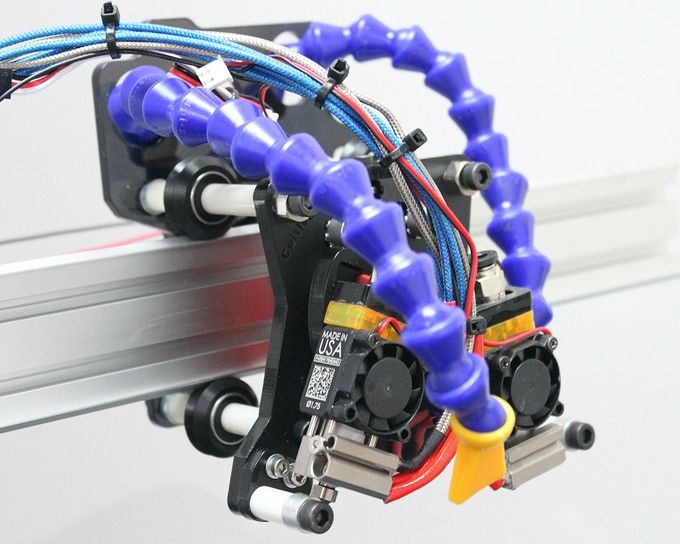

The Medusa approach is quite intriguing: Both hot ends are mounted on the motion system. To engage one hot end, it rotates downward. When it tips, the other hot end rotates correspondingly and is blocked from leaking material.

This allows the “other” hot end to remain at operating temperature and thus it can be used instantly when rotated back into position. This approach seems to solve both problems encountered with other techniques.

You can talk about “print speed”, but extrusion advantages melt away when time is spent moving hot ends around. This simply doesn’t occur with the Elevator.

Elevator 3D Printer Components

It seems that Cultivate3D has gone all-out to select the best possible components for the Elevator 3D printer. In their material it’s explained that they attempted to use various popular components and ended up with their selection based on experience with the machine. If it didn’t work well, it didn’t make it into the machine.

For example, the hot end originally used was the very popular E3D-Online V6. However, the Cultivate3D team found this component’s configuration really didn’t work well with their system, and instead they changed to use Slice Engineering’s Mosquito Magnum.

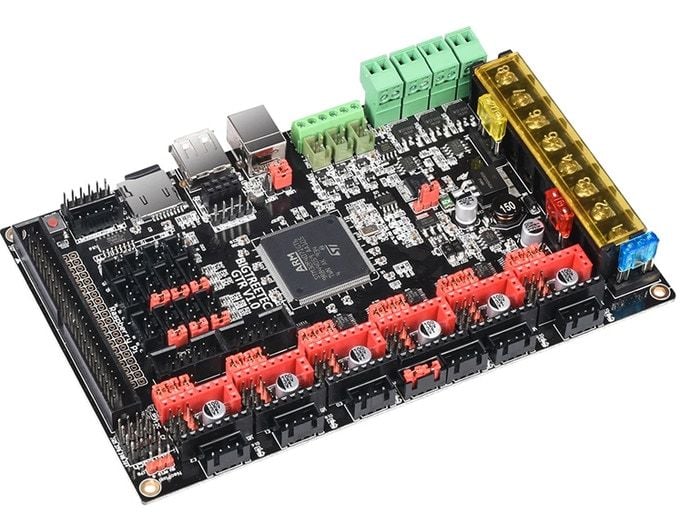

Similarly, they spent considerable time evaluating controller boards and ended up with the 32Bit Bigtreetech GTR mainboard, after discarding multiple other options.

Finally, in a surprise move, they decided NOT to use the increasingly seen silent TMC drivers. This approach results in a near-silent operation of the 3D printer. However, Cultivate3D explains that while they are silent, they can incur torque issues and thus they avoided using them. You’ll find the Elevator 3D printer to be not only big, but a bit noisy.

However, the standard Elevator system includes a housing so the build volume is enclosed to capture stray heat — and sound.

Cultivate3D Shipping

There’s one other curious aspect of this 3D printer, and it’s one that I think other 3D printer manufacturers might take a good look at: their shipping philosophy.

To save on shipping costs, Cultivate3D decided to offer the Elevator as a kit. This meant it could be broken down into smaller subcomponents that might be packed quite tightly. That’s something that’s been done, but get this: there’s no built plate.

On a very large machine the build plate is a huge component. For this device the build plate will literally be larger than 1000 x 660 mm. For a plate made of aluminum or glass, that’s a huge and heavy item to ship.

So Cultivate3D simply left it out. The idea here is that a buyer would be easily able to purchase either glass or aluminum locally to fit. They say the cost of shipping is quite literally worth more than the plate itself, and I don’t doubt it.

Finally, they offer another way to save with the “Elevator Naked” 3D printer offer. The “Naked” part refers to a lack of enclosure, which again will save on shipping costs. Instead they’ve designed the Elevator to have perfectly flush exterior sides, and so an operator can easily bolt on any type of simple enclosure required.

These ideas are quite innovative, and I suspect other 3D printer manufacturers might take note.

Elevator 3D Printer Costs

The big news, after all those fascinating features, turns out to be the price. The Elevator kit is available for only US$4,830. While that’s a lot more than the cost of a typical desktop 3D printer, the Elevator offers a build volume more than FORTY times as large!

The Elevator Naked ships for a price of about US$3,780.

These prices should be compared to the 3D printers from BigRep or 3D Platform, where price levels are literally 10X as high. However, the Elevator requires assembly, whereas the others do not.

If you’re interested in this huge 3D printer, you might want to check out their new Kickstarter where the Elevator has just been launched.

Via Kickstarter and Cultivate3D