Authentise has teamed up with Addiguru to bring in-processing monitoring into its additive manufacturing workflow.

The company, well known for its Authentise Manufacturing Execution System (AMES), has partnered up with a number of high-profile companies to enhance its additive manufacturing workflow tools — among them you might recognize the likes of Microsoft and Autodesk on the software side, and EOS among the 3D printing OEMs on the hardware side. Authentise is working toward goals larger than market share, as the company has even teamed up with the competition to provide better tools for users.

Today, though, Authentise has announced a new integration with Addigru, which provides real-time monitoring solutions for additive manufacturing. Real-time monitoring is fast becoming a must-have when it comes to industrial 3D printing, as understanding the in-situ happenings during a print job can forestall failure. Quickly detecting — and then of course addressing — anomalies can mean the difference between success and costly failure.

“I think this is the first time this has happened in the industry and brings us one step closer to the ideal of being able to qualify the part completely based on the data that is being aggregated. Addiguru is a great partner, and validates our theory that startups will spring up around specific functionality in the workflow, which we can integrate. Of course we stay open to others in line with our ‘open’ policy,” Authentise CEO Andre Wegner told me of the announcement.

That announcement indicates some of the specifics users can anticipate:

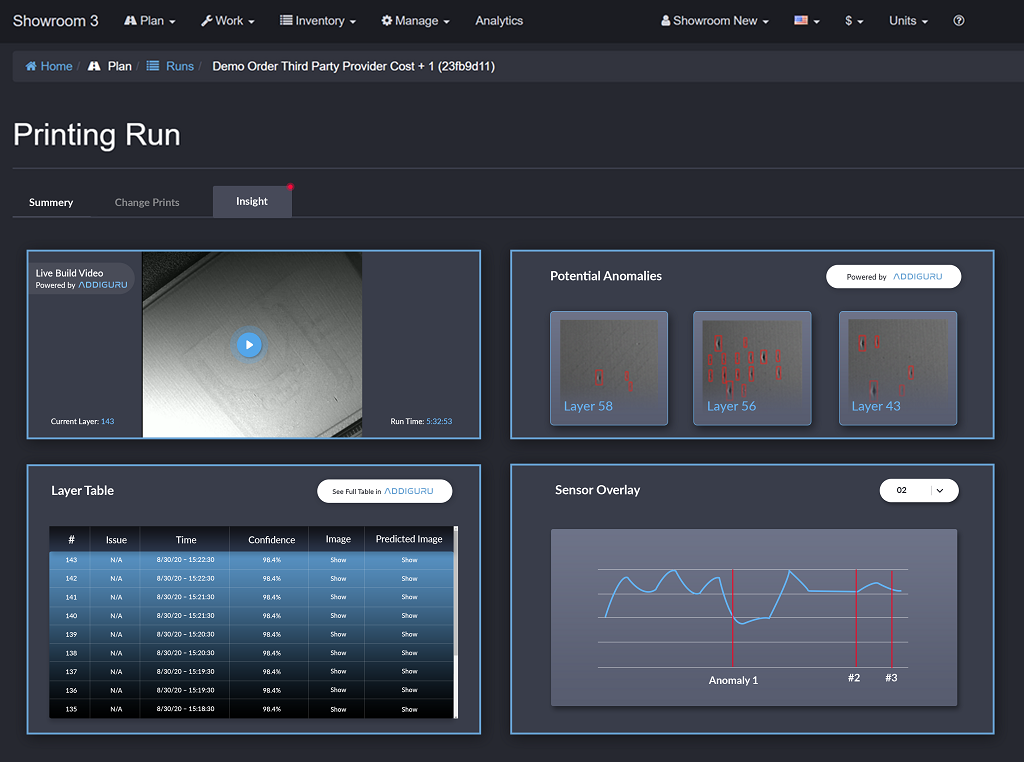

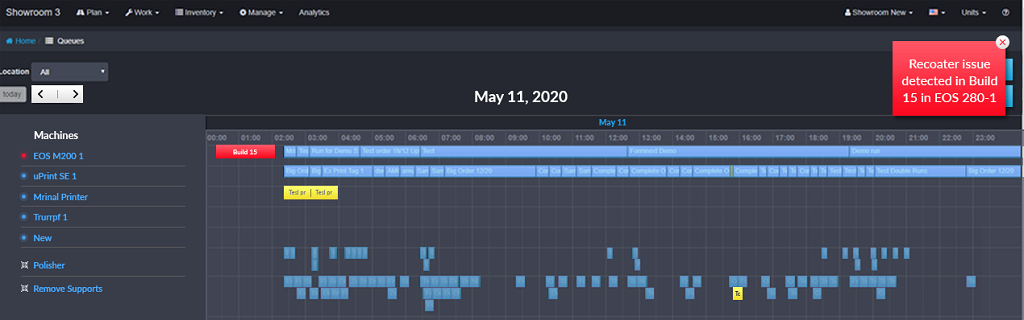

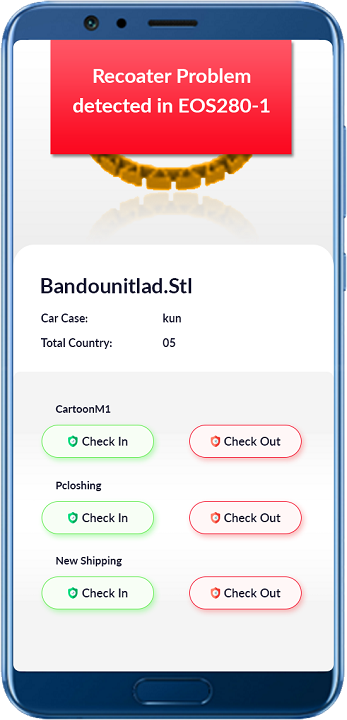

“Alerts from the Addiguru algorithms create real-time notifications within the Authentise web interface and app, display images highlighting potential issues, and visually spotlight the alert within the full workflow view. The full data suite of images and findings is automatically added to the real-time traceability alert and in a new analytics section for each machine and build. This includes the ability to overlay detected anomalies with sensor data taken from Authentise’s unique access to machine data. Each user can also use this data to create custom alerts, reports and dashboards.”

Authentise, Wegner says in the release, brings “coherent control of the digital thread and access to machine data,” while Addiguru “can add visual inspection and intelligent analysis.” Leveraging the strengths of each company can ultimately offer a better, more complete tool set to the additive manufacturing user.

“Existing in-process monitoring tools either require the user to have spent days setting up trial prints or to click through every image to detect potential flaws. The combination of our AI-driven insight and Authentise’s workflow tools enables the user to gain practical benefit in a system they love by having all data and notifications in one place.” says Shuchi Khurana, CEO of Addiguru “This initiative with Authentise also moves us closer to our goal of an open architecture framework.”

Via Authentise and Addiguru