Additive Industries announced a partnership with Sigma Labs to allow use of PrintRite3D on their equipment.

Additive Industries, based in Eindhoven, The Netherlands, produces an integrated metal 3D printing system called MetalFab1. The company was among the first to recognize the several steps required to complete metal 3D printing, and produced a system that integrated them together to increase productivity.

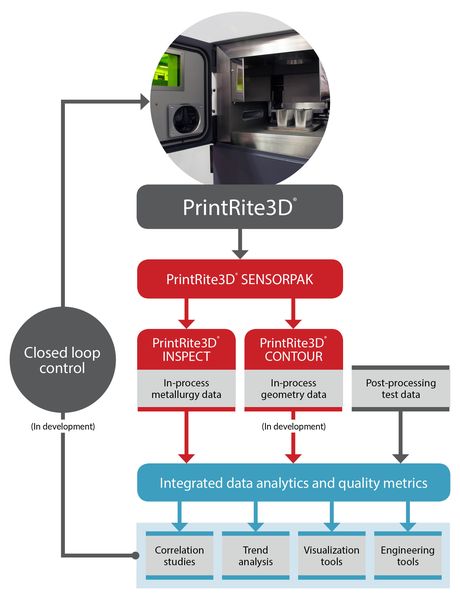

Meanwhile, Sigma Labs produces a closed-loop control system called PrintRite3D. This system relies on a series of sensors within a 3D printer to provide real-time data for analysis. The system can provide a way to increase print quality, limit scrapped materials and provide quality audit information for 3D printers.

The announcement says:

“In a joint partnership of the engineering teams of Sigma Labs, a leading developer of in-process quality assurance software for the additive manufacturing industry, and Additive Industries, the MetalFAB1 is now qualified as PrintRite3D Ready. This will allow the MetalFAB1 to be equipped with a melt pool monitoring solution. Ready for up to four full field lasers and real time multi-laser visualizations, the integration of the PrintRite3D Melt-Pool Monitoring solution is a valuable addition to the MetalFAB1 product. Real time visualization can be viewed in 2D or 3D and potential anomalies in the part will be highlighted.”

The MetalFab1 already provided significant efficiency with its integrated design, and achieved excellent part quality. However, this arrangement with Sigma Labs could take the output to the next level.

This relationship will be of significant interest to certain types of clients and prospects for Additive Industries, and those would be applications where extreme part quality is required. It’s quite possible this will unlock access to a new set of clients for the company.

The system could also provide a way for clients to more quickly certify the completeness of 3D printed parts. This aligns with Additive Industries’ long-term strategy to increase the overall efficiency of metal production workflows.

For Additive Industries’ metal 3D printing competitors, the bar just raised a little higher. There may come a time when this type of quality control will be expected on any metal 3D printer.