As promised, RIZE is debuting its latest composite 3D printing material: RIZIUM Glass Fiber is available now.

“We are a 3D printing technology company and a materials science company — we’re more materials science-led than anything,” RIZE President and CEO Andy Kalambi told me recently when we caught up about progress at the company, especially with the collaborative industry-focused RIZIUM Alliance.

He teased at the time of that conversation the upcoming release of RIZIUM GF, a glass-filled composite set to join RIZIUM One and RIZIUM CARBON filaments in the RIZIUM portfolio. That day is here, and per RIZE the new material features:

“High dimensional stability, exceptionally durable composite material suitable for full-color applications and complex geometries and UL’s GREENGUARD Certification for low emissions.”

There’s a lot to unpack there; let’s start with GREENGUARD.

UL GREENGUARD-Certified 3D Printing

RIZE has been among the companies in the industry leading the charge for actually sustainable 3D printing. Among the ways they’ve sought to achieve this is genuinely zero-emissions 3D printing with their desktop systems.

To further their claims of sustainability, RIZE went to a trusted source: UL. The global safety certification company does not issue its stamps of approval lightly, so we can be assured that when we do see the UL approval on a technology, real standards have been met. RIZE has been consistently meeting those standards, and last year the RIZE One became the first GREENGUARD-certified 3D printer.

The UL 2904 GREENGUARD Certification has now been awarded to the RIZE One monochrome 3D printer, XRIZE full-color composite 3D printer, RIZIUM ST filament, RIZIUM inks — and now RIZIUM GF filament.

The XRIZE, RIZIUM ST composite, and RIZIUM inks certifications were announced just at the end of this July, adding to the initial October 2019 RIZE One announcement.

The certification confirms, says RIZE, that “it is safe to be used in offices/schools/hospitals and any enclosed spaces.”

I spoke at length with Kalambi about the significance of the GREENGUARD 2904 certification when the company announced its first such achievement. He brought it around to a greater-good-for-the-industry perspective, noting:

“I think a lot of focus in this industry has been on how to create the part — and rightfully so: at the end of the day, what people want is the part. In consumer 3D printing — which could be engineers, design technicians, or any of those who consume the parts they make and drive 3D printing — we want to highlight the point that it’s also the user experience that matters, because the safety, the ease of use we’ve been talking about, are as important as the part. Otherwise the printer will sit in a cage somewhere, unused. Or, as standards come out and people realize their printer is not safe, it will be put back in a cage and unused. We want to be sure 3D printers can move upstream and downstream, and to be able to do that, the user experience innovation is as important as the part-level innovation.”

That is, a certified-safe system is much more likely to be regularly used. And it’s good for all of 3D printing when purchased 3D printers are actually used.

Kalambi seemed positive upon the initial announcement that the 3D printing industry would continue toward a future of more GREENGUARD-certified technologies, ensuring lower VOC (volatile organic chemical) emissions and a generally safer operating environment. While we haven’t heard too much yet, the age of GREENGUARD in 3D printing is still young.

RIZIUM Glass Fiber

Onto the new material itself: meet RIZIUM Glass Fiber.

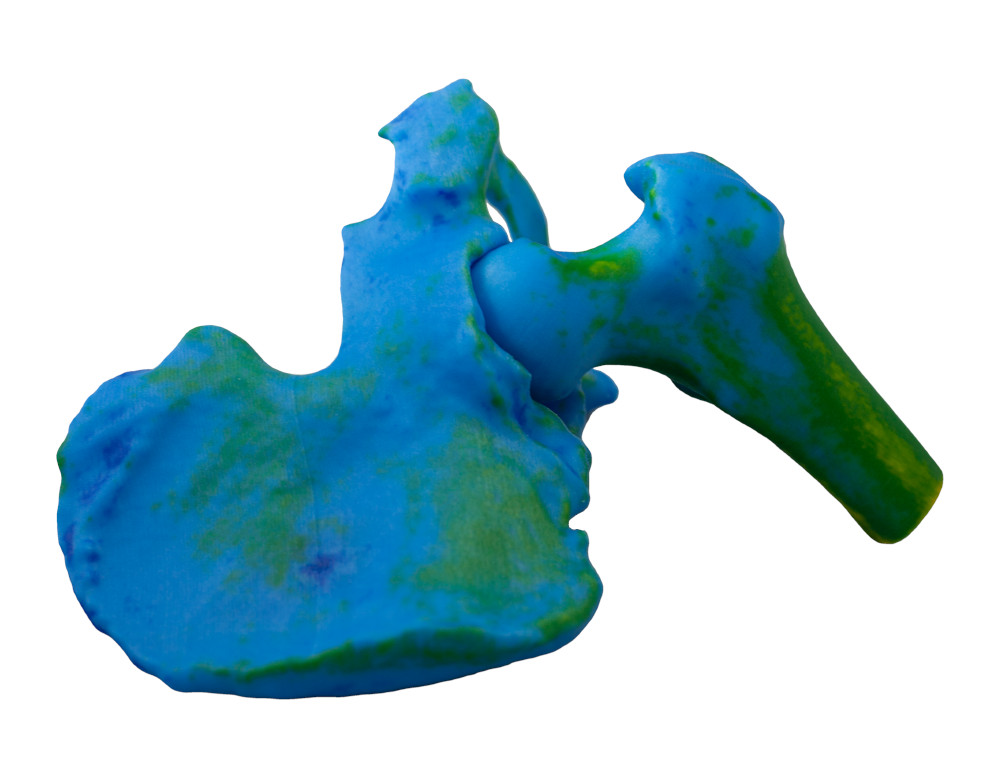

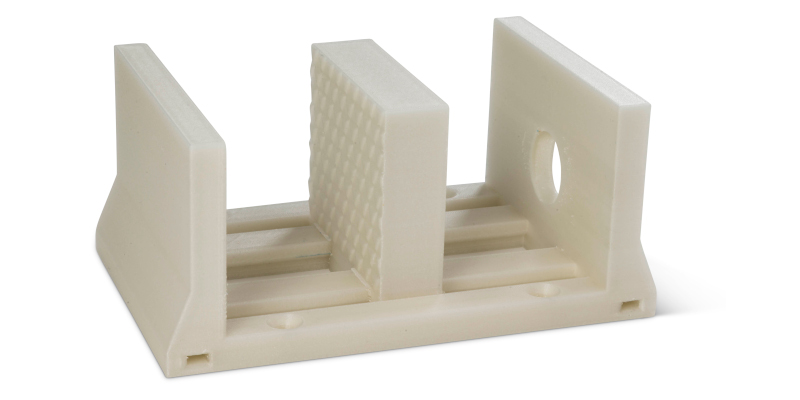

The filament was developed for professional use, with high dimensional stability, high stiffness for strength in large parts, and life-like color capabilities in mind. It also offers low moisture absorption, high chemical resistance, and, of course, no emissions released at extrusion temperatures.

Companies like Azoth have already been using the new GF material, reporting print reliability, quality, and strength.

In today’s announcement, Kalambi explains of the RIZE perspective on the material:

“Until now full color 3D printing applications could only deliver weak approximations of the original, and users often avoided large parts or complex geometries because they could warp or crack. We’re delighted to help drive a renaissance in industrial manufacturing with better 3D printing materials and technology. With RIZIUM Glass Fiber’s high dimensional stability and durability, and GREENGUARD Certification for low chemical emissions, users have the flexibility to expand the applications suitable for 3D printing. Expect to hear more from us soon about further expansions to our RIZIUM Alliance so that all 3D printing users can work in safer, more sustainable and adaptive environments.”

Via RIZE