I’ve been doing some thinking about a potential Prusa MK4 3D printer and have some ideas about what we might see. However, there have been no announcements about such device.

This is part two of a two-part story on a potential Prusa MK4 3D printer. Please read part one.

Prusa MK4 Open Filaments?

Today the entire line of Prusa Research equipment is organized around the principle of open materials, where any suitable material from any supplier can be at least attempted to be used on the machines. I don’t expect that to change at all.

However, the ability to use random materials does introduce the possibility of mis-matching the sliced code with the physical material. For example, imagine preparing a print job for PLA but ABS is loaded — the print won’t work very well. This depends utterly on the 3D printer operator to ensure the two match.

The only way to avoid this potential problem is to somehow have the machine be aware of the type of material loaded on the machine at that time. Other vendors handle this with proprietary materials with RFID chips read by the machine. I think that’s a very unlikely change for Prusa Research to consider.

Until there is some kind of industry standard for automated spool identification — and one actually used by the majority of filament suppliers, it’s unlikely Prusa Research would introduce a feature of this type. We’ll likely continue with the current mode of “unknown spools” in a MK4 device.

Prusa MK4 Print Plate?

I don’t see the company moving away from their highly successful spring steel / coated approach used today. That must be one of the most reliable and functional methods of adhering prints, and I can’t see them changing it radically.

They may, however, introduce a means to automate their “Steel Sheet” tracking system. Currently this system allows the 3D printer operator to ensure the correct type of sheet is installed and configured for the next job, as there are two types, with perhaps more to come in the future.

At this time there is no way for the 3D printer to “know” which sheet is physically installed, and it is dependent on the operator to indicate the sheet profile to use. However, it might be possible to install a simple mechanism to detect the sheet when installed so that the machine can automatically configure itself.

That would simplify operations somewhat and eliminate one type of operational error.

Prusa MK4 Interface?

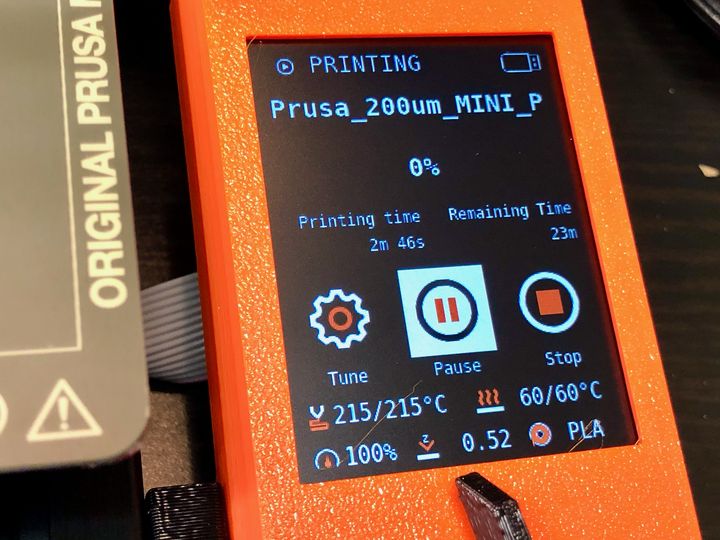

This is one area we could see substantial change. The current MK3S device sports a rather unimpressive digital LCD display that’s hard to read and doesn’t have the space to show very much. It works, but really it’s a device style from years ago.

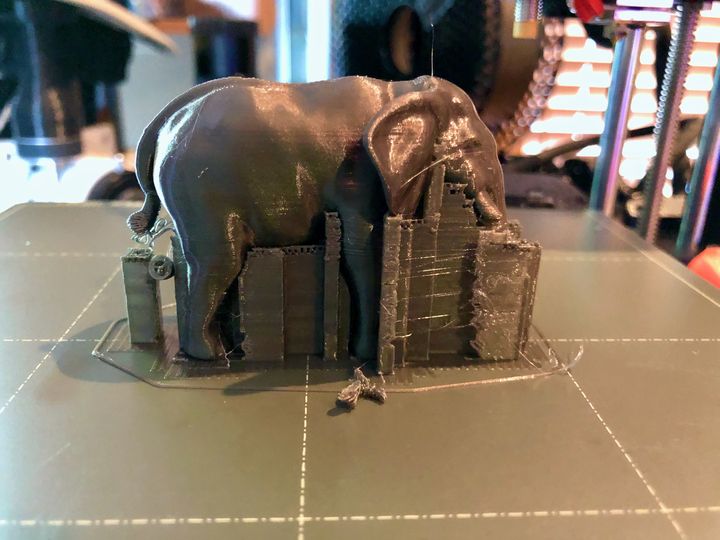

One big clue could be from the Prusa MINI, on which the company seems to have experimented in several ways. This tiny 3D printer has a color non-touch screen that shows all manner of information in an easy-to-use layout. There’s even a full 3D preview of the object being printed.

I expect to see a very similar interface appear on the MK4, and it may be they offer a touchscreen version, whereas the Prusa MINI had a large push-wheel.

Prusa MK4 Convenience Features?

I’ve noticed several other low-cost 3D printers have begun to offer unusual convenience features, such as an integrated tool drawer, carrying handles or built-in tabs to hold down the print surface. Could Prusa Research be considering similar convenience features?

I’m not sure there would be much here for a MK4 machine, as these features are generally optional from a functional point of view and would needlessly add cost to the device.

A carrying handle would be nice, though.

Prusa MK4 Electronics?

Prusa Research has consistently upgraded the electronics board in each of their successive machine releases. The MK2 included a 12V Mini Rambo 8-bit board; the MK3S includes a 24V Einsy Rambo 8-bit board.

One of many improvements in the recent Prusa MINI 3D printer was the electronics. The MINI boasts a custom-made 32-Bit Buddy board that has a lot more oomph than the EINSY RAMBo board in the MK3 series. It’s likely this board or a similar but more powerful 32-bit board will make its way into the MK4.

Another change likely in the MK4 will be the same as the Prusa MINI: loss of warranty when non-standard firmware is flashed to the board. This is likely due to incidents that caused the company time, effort and money in the past. Once they’ve deployed this approach on the Prusa MINI, it’s clear they’ll likely do the same on the MK4.

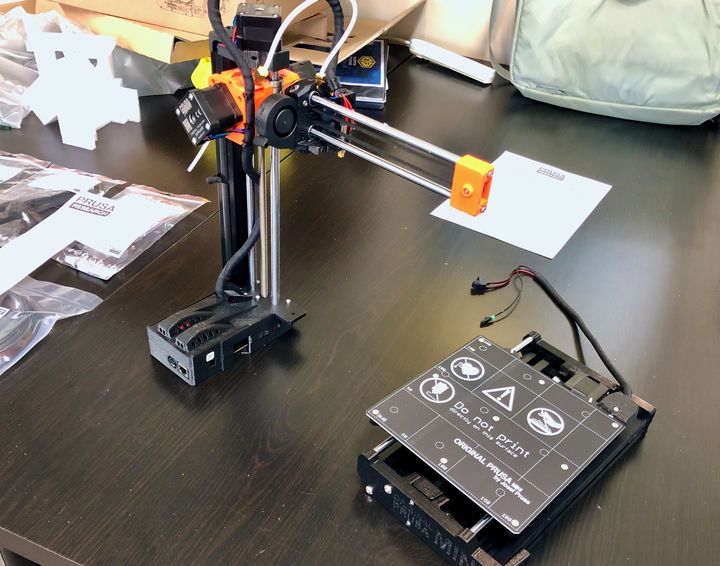

Prusa MK4 Frame?

One of the MK3’s improvements over the MK2 was an improved frame, particularly on the Y-axis. The MK3 frame is far more rigid, which led to increased print quality since the axes weren’t quite as wobbly.

Could the frame be made even more rigid? I think it could, and I wouldn’t be surprised if Prusa Research were able to find an inexpensive way to make the MK4’s frame even more robust. One popular third party upgrade to the devices is the “Bear” upgrade, which is an aluminum frame conversion kit for the MK2 and MK3 machines. It makes the frame far more rigid and increases print quality.

Prusa Research have likely learned much from the sparse design of the Prusa MINI, which is quite rigid even though it has fewer frame components. In a way, the Prusa MINI is somewhat Bear-like, and it’s possible we’ll see more of this on a future MK4 device.

Prusa MK4 Speed?

This is an area where it’s possible we may see a significant improvement.

Let’s put this together: if the MK4 has a more rigid frame and a more powerful controller board, it may be possible to drive the printer at faster speeds. The board should be able to compute movements more rapidly and thus be able to control the motion system at higher speeds. By how much? Who knows? It would likely be as fast as the Prusa engineers can make it perform on a reliable basis.

Prusa MK4 Print Resolution?

I’m not looking for increased print resolution on the MK4 because it really isn’t necessary. If you can 3D print at below 0.1mm layers, which you can on the MK3 with some tuning, then why do more? You’d just slow down the print jobs, even with a speed increase. Halving the layer size means twice as many layers to print.

That said, I think they’ll be closely looking at the usage of the Prusa MINI, which can easily 3D print at 0.05mm layers. It takes forever, but has outstanding results. If they find it a frequently used option, then perhaps a higher-resolution option would be provided on a MK4 device.

Prusa MK4 Power System?

The MK4 will certainly continue using a 24V power system as used in the MK3S.

However, one possibility is that we could see a higher-rated power supply that could heat up the hot end and print surface more quickly. Those are two aspects of current 3D printers that take time, and if one could make that happen faster at a reasonable cost, I think 3D printer operators might appreciate this speedup.

Prusa MK4 Sensors?

Many more advanced (read: more expensive) 3D printers achieve high print quality through the use of numerous sensors that can help control the print activity in real time. The MakerBot Method X, for example, includes over 20 different sensors.

It may be the MK4 could include a few more sensors specifically for increasing print quality. Unlike the Method X they will not be monitoring chamber temperatures, as the MK4 will probably not include an enclosure. Instead the sensors could be used to help monitor consistent filament flow, jamming, motion system accuracy, etc.

These may be able to notably increase the print quality and reliability of the MK4.

Prusa MK4 Rollout?

That’s some general ideas I’ve been thinking about for the MK4. While we have had essentially no indication there is such a machine, it’s inevitable that Prusa Research will eventually replace the MK3S with something else in the future.

One more possibility is that the company does NOT release a “MK4”, but instead gradually incorporates some of the ideas above and others into a slightly better version of the MK3S. Perhaps it could be called the MK3S Plus, or something like that.

I’m watching for developments.

This is part two of a two-part story on a potential Prusa MK4 3D printer. Please read part one.

Via Prusa Research