There’s a new industrial filament 3D printer in the works that could operate seven to nine times faster than conventional devices.

Vancouver-based Pantheon has been operating quietly for some time, but is only now beginning to show their project to the public.

Pantheon Background

The two founders, Bob Cao and Alex Wiecke, met in university and continued to collaborate on projects for several years, mostly involved in restoring vehicles and electronics projects. Often they found themselves faced with needing to replace a crumbling bakelite fixture on an ancient motorcycle.

They turned to 3D printing, as they felt it could be a technology that might be able to replicate the missing components. As they could not afford a professional machine, such as one from Stratasys, they began work using the far less expensive Da Vinci series from XYZprinting.

They “gave up” trying to successfully 3D print ABS material on this device, as it simply wasn’t capable of producing ABS parts of sufficient quality.

Then, a couple of years ago, the Ender V3 arrived and they were able to successfully produce useful parts, albeit with long print times in their small workshop in a co-working space. Usually the team would produce prototypes of metal parts for their vehicle projects, but they also used plastic parts for end use.

But like many users of 3D printing, they found they “needed better everything”, as well as a larger size to produce the required parts for their projects.

Designing A High-Speed 3D Printer

Being engineers, they decided to take on the challenge of developing their own machine to overcome these difficulties. However, they used a different approach from almost every other 3D printer manufacturer: they re-examined the problem of printing from base principles. This was a study of motion, chemistry, temperature, materials and more, something that really hadn’t been attempted since the early days of 3D printing.

Essentially they designed a device that is literally a combination of the printing system and materials. In other words, the materials were designed for the system and the system was designed for the materials. I’m not sure any other 3D printer has this type of heritage.

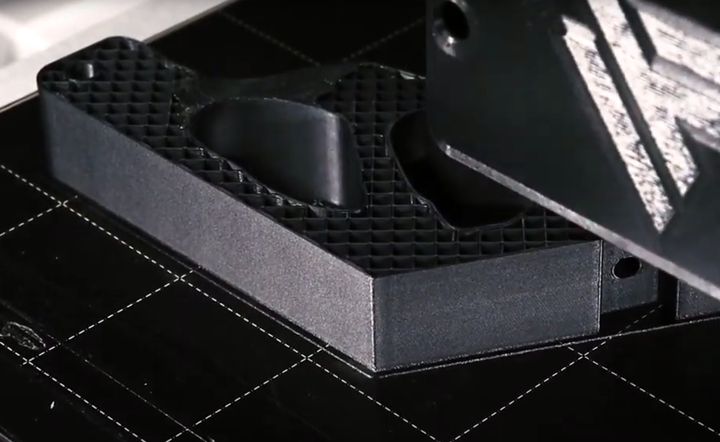

All of their materials are carbon composites, which makes the resulting prints very strong, and thus useful for end use.

The company began using the device for its own projects with industrial clients. At first it was just for fun, but they kept accumulating more clients and eventually realized they could turn this into an official business. Incorporated only a year and a half ago, they have grown from the original two to now nine staff.

As they took on more projects they had to develop more additive technology to ensure they could complete the projects successfully. This gradually built up the capabilities of their device.

Eventually clients began to ask whether they could purchase one of Pantheon’s machines. The team decided to initiate a “high-speed project” to develop just such a machine, and that’s what is in progress now.

High-Speed Pantheon 3D Printer

Their target is to develop a filament-based 3D printer capable of producing parts at 10X the typical rate, and it appears they are almost at that point, based on the live demonstration I saw, and the video they’ve recently released:

Note that this video is shown in real time. It is NOT sped up!

How is it they can 3D print so fast? They won’t tell me, but do say they used a “little sprinkle of science”. While the motion system is from earlier machines, their deposition and extruder technologies are entirely new and unique in 3D printing.

Based on the science behind extrusion, they completely re-designed the hot end and extruder from ground up, and now find they can 3D print objects 7-9X faster. They say the secret is in the polymer materials they’ve custom designed for the device.

Pantheon says the previous print time for typical objects on their projects would take from four to seven days to complete. Now, with the high-speed device they are able to complete them overnight.

Pantheon 3D Printer Availability

Currently they’re using the machine for use on their client projects, which continue, but they are also gearing up to sell machines in the future.

Their plan is to produce a very small number of units and place them with interested industry partners for feedback. At this time they are taking pre-orders for this limited set of devices, which may ship sometime early in 2021. They expect to be selling units to the public later that year through a direct sales approach.

I don’t know the specifications of the machine, but I can tell you this is an industrial device with a very large build volume. It will require compressed air service to operate, and the as-yet unnamed machine includes a very heavy motion plate. This is most definitely not a desktop device.

I’m very interested to see how this project proceeds, as it seems to have few parallels with other 3D printer manufacturers.

Via Pantheon