For decades, many CAD users have looked askance at data for any purpose made from point clouds, or polygonal meshes.

Despite early attempts in the 1990s at virtual reality markup language (VRML), CAD software didn’t do much with mesh data aside from tessellated displays and FEA type applications. CGI data and other emerging types, such as scan data, info from radar, satellite and drone scans, voxels, anatomical data from MRI or CT, were left to other specialists and haven’t had much foothold in the world of mechanical design.

Mesh data can be represented in many ways:

- Mesh

- Polygonal mesh

- Point cloud

- Subdivision (or subd, pronounced SUB dee)

- Pixels/voxels

- Tessellation

In some data types, the points are important. In others, the connections between the points are important.

Raster graphics assign colors to individual pixels (like a bitmap). From there it becomes easy to represent a set of 3D points in various colors projected onto a 2D screen. Computer-driven animations are ubiquitous today and used in just about every area of visual communication. CGI tools let us create and animate organic shapes from point data much more easily than using math-driven NURBS surfaces.

Finite element analysis (FEA) methods also make use of large matrices of point data. Stress and thermal analysis, though far removed from CGI, have 3D point data in common. FEA methods also are useful for design with shape optimization and generative design.

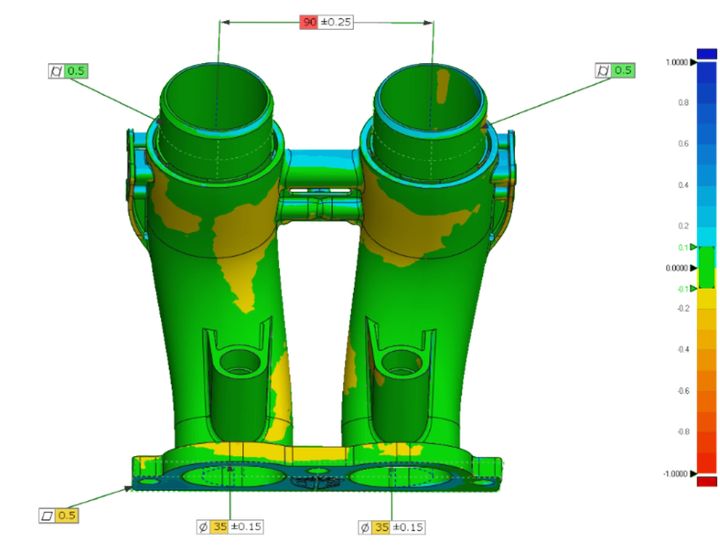

3D scans give us the capability of collecting polygonal mesh data from mechanical probes, scans using lasers, structured light, radar and even sonar. This gives us information on everyday objects we want to represent as computer models, as well as larger items, such as ships, buildings and even landscapes captured from satellites in orbit.

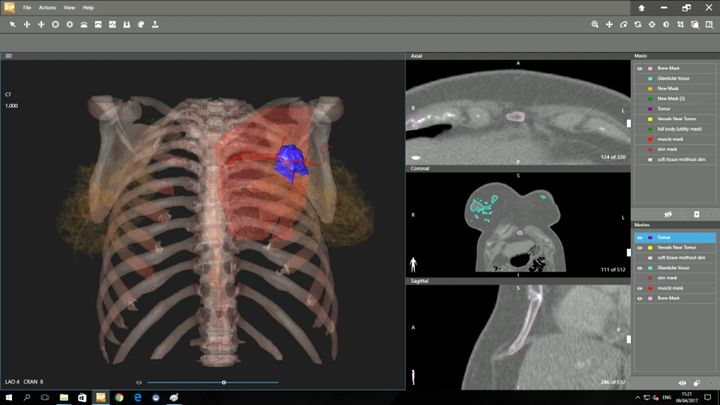

Healthcare is another industry that makes use of this type of data. Computerized tomography (CT) and magnetic resonance imaging (MRI) scans record various properties for each point in a 3D slice of a patient’s body. This gives technicians a detailed map of internal organs.

3D printing also uses point cloud data. It’s increasing use in industry has made for an expanding list of materials, processes, machines, competitors and applications where the techniques can be used.

One company has been increasingly working with all of these applications of mesh data connected to CAD and engineering. 3D Systems started 35 years ago as Chuck Hull’s vision in a lab. Hull was granted a patent on the stereolithography process in 1986. Stereolithography uses beams of ultraviolet light to cure liquid resin into solid polymers. An abbreviation for the process name became the file extension for the STL data format. Stereolithography was just the tip of the iceberg for 3D Systems, but it served as a springboard for the company to get involved in many vertically integrated businesses all related back to the collection, processing of mesh data, and additive manufacturing.

3D Systems’ growth both in size and in capabilities has been driven in part by acquiring other companies and products. Each acquisition gave it another piece of the additive manufacturing puzzle.

Some acquisitions that you may recognize were Alibre (CAD), Rapidform (scan-to-cad), Geomagic (a best-in-class mesh processing tool), Sensable (3D haptic stylus), Cimatron (CAM), GibbsCAM, and many others. You can see an obvious strategy at play in these acquisitions as they are all related to creation, collection or processing of mesh data or products directly created from the scan-to-manufacture process. 3D Systems doesn’t just sell the tools. They also supply services using those tools.

Through this strategic growth and acquisition, 3D Systems has come to be a player in several industries, including:

- Aerospace/defense

- Automotive

- Healthcare and dental

- Manufacturing and design

Let’s take a look at these industries one by one.

Aerospace, Defense and Automotive

3D Systems’ involvement in the aerospace, defense and automotive industries has happened in a couple of different ways. Of course, large scale manufacturers like prototypes of a design. Evolution in both materials and processes have improved the capabilities of printing metal with resolutions down to 0.0012” with densities between 96 and 100 percent.

If you have ever tried to source a mold for plastic parts, you know what a pain that can be. Using the metal processes, you can have a printed mold cavity and core inserts within days after designing them. Or, you can 3D print wax patterns for creating complex investment or lost wax castings.

Healthcare and Dental Applications

3D Systems’ involvement in medical applications is impressive. D2P (Dicom to print—where Dicom is digital imaging and communications in medicine) software enables health professionals to create physical 3D models of actual internal organs for visualization, diagnostic, or training purposes from actual patient scan data. This data can also be turned into virtual reality (VR) models for digital-only visualization, used again in training and diagnostics.

Read more at ENGINEERING.com