Researchers from the University of Massachusetts have developed an unusual hybrid 3D printing process that both speeds and strengthens prints.

They call it “Injection Printing”, as it might be viewed as a combination of 3D printing and injection molding. The concept is actually pretty straightforward, but then when you think about it more deeply it becomes extremely complex.

The researchers realized the standard injection molding process is a lot faster than typical 3D printing, as the entire volume is created at once, whereas a 3D print job may require all voxels of the object to be traced by some means. That can be sped up somewhat by methods such as simultaneous layer creation in processes like DLP or DLS, but it is still a layer-by-layer process.

Those very layers that define the 3D print are usually the weakest portion of the final object, as the adhesion between layers is far less than what one would find in a solid block of injection molded material. Thus the typical 3D print failure is delaminated layers.

Their concept is to make use of injection molding techniques during a 3D print. Here’s how it works:

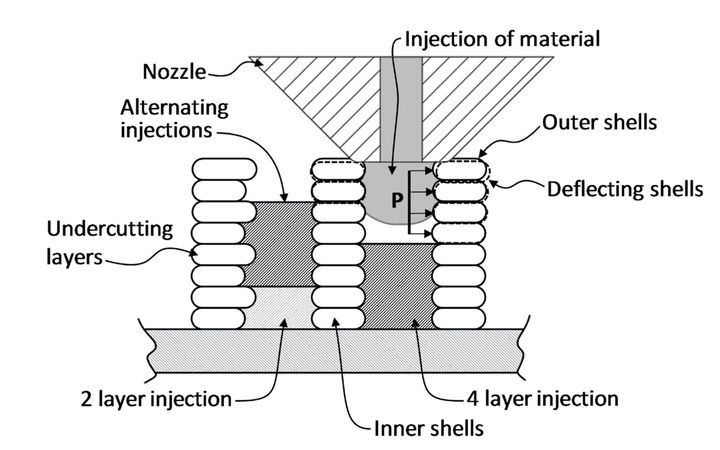

A normal FFF 3D printer builds a small, hollow structure, essentially some walls surrounding a void. Then hot, melted material (the same material as the walls) is poured into and fills the void. The 3D printed walls act as the mold in this process.

The resulting object is, as you might guess, 100% solid infill. But since the injected fill material bonds to the walls, there is far greater overall strength of the object. The strength is near identical to injection molded pieces as most of the mass is essentially injection molded. However, the “mold” remains part of the final object.

I’ve seen previous attempts at filling 3D print voids with material to make them stronger; in fact, a story on that approach is one of our most popular pieces. However, those techniques are manually performed and typically done AFTER the 3D print completes, not during the 3D printing process itself.

The intention of the researchers was to develop a process that could be entirely automated. And that’s where the complexity begins.

Consider some of these challenges:

How can you ensure the fill material actually bonds well with the walls? The researchers eventually developed a slicing technique where the inner walls would have occasional protrusions that would be able to catch the injected infill.

Another issue is heat: what if the heated injection is so hot it melts, distorts or even breaches the walls? How thick must the walls be? What maximum temperatures can be used?

Geometries pose another issue: while it’s easy to imagine block-like objects being filled in this manner, there are plenty of geometries that would be pathologically bad for this, like a sculpture with plenty of spindly appendages.

Another geometry issue is that the voids within an arbitrary 3D model may not be conducive to injection at the end of the print. They may be discontiguous, trap air or be too small to bother with. This suggests a complex analysis of the voids and injection sequences would be required.

For complex voids one can also imagine thermal problems as a liquid material slurps through passages but cools along the way. Some geometries might cause prematurely frozen materials that could block injection flows.

It’s also possible that in a small part the 3D printed walls may not have completely solidified before they are subjected to an onslaught of molten injected material. This could cause a breach of the walls. The researchers developed a way to segment the voids to only a few layers, where they would be injection-filled. Thus the 3D printed part could end up to be a three-dimensional checkerboard of filled voids surrounded by 3D printed material.

The researchers also found that most FFF 3D printers do have the capability of performing this process to some degree. They calculated the potential heat and flow rate of most extrusion systems would be sufficient to pour out the injection material if so directed. However, they recommend using alternative toolheads optimized for flow if full speed is required.

They believe the process could produce parts as much as 3X faster than normal 3D printing, but with much stronger results.

It’s not clear where this invention may go, as it is not available in any current 3D printer we’re aware of. It is possible the researchers may patent the process and eventually commercialize it in some way.

I can imagine a future 3D printer that would have a second toolhead for this purpose, accompanied by sophisticated slicing software to drive them both. The resulting parts could be far stronger and obtained in record time.

Via Science Direct