HP has entered into a strategic partnership with Dyndrite, underscoring the critical importance of software to the long-term success of industrial 3D printing.

For additive manufacturing to effectively rise as a solution in wider adoption, three key aspects must come together: hardware, software, and materials. Advances in any one area cannot be completely effective without tying in to the other two to create a full workflow that can operate in concert.

Understanding this, when Dyndrite emerged from stealth last year with a promising new idea for a geometry kernel, the company also introduced the Dyndrite Developer Council (DDC). At launch, the DDC was referred to as comprising “a select group of industry leaders committed to advancing the accessibility of the additive manufacturing industry.” Unsurprisingly, HP was among the familiar names of the inaugural DDC.

“As the first member of the Dyndrite Development Council, we quickly identified areas where Dyndrite’s innovative technology could be applied to solve the larger challenges facing the AM industry,” said Ryan Palmer, Global Head of Software, Data and Automation, HP 3D Printing & Digital Manufacturing. “For too long the additive industry has been in a state where the capabilities of the manufacturing devices exceeded the ability of the software needed to support them.”

Dyndrite 3D Kernel

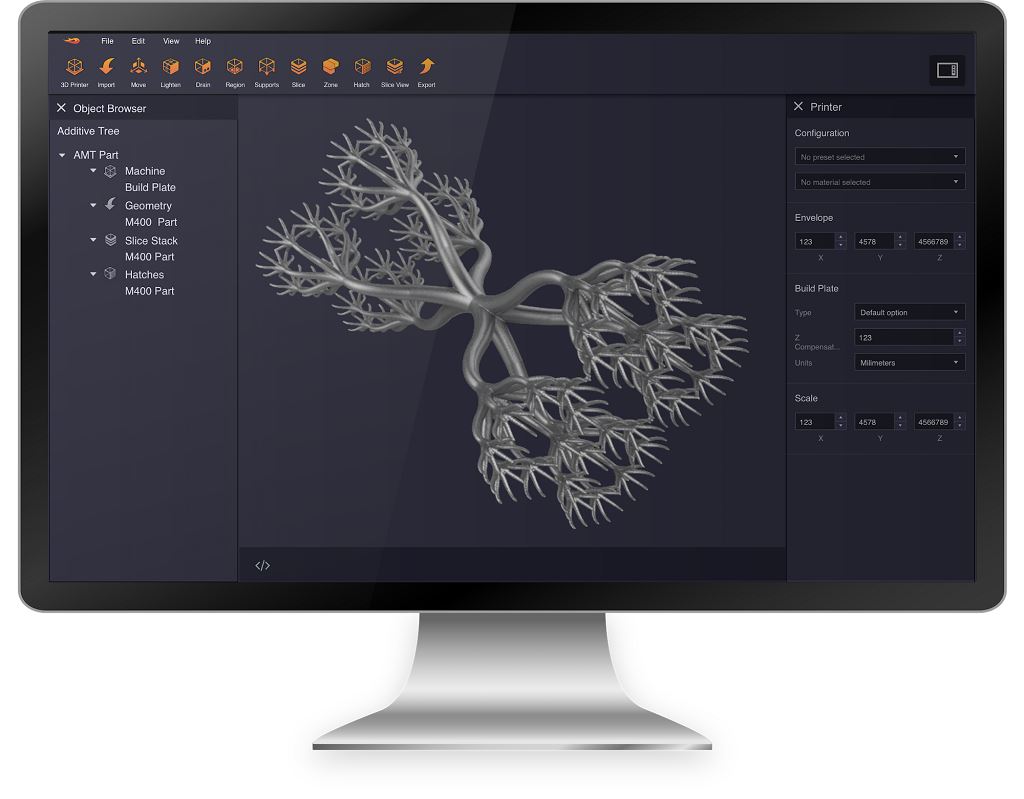

Backing up a moment, the great promise of Dyndrite is in its geometry kernel.

Kerry took a good look here at what a kernel is and what theirs might mean to 3D printing, but in short, a software kernel is the fundamental core of the system from which all other services and activities are drawn. And Dyndrite believes 3D technologies are well and truly due for an update, as they noted that the last major happening for the 3D kernel was in the 1980s. That one, Dyndrite noted, was for legacy needs.

The kernel is a component upon which software can be built — so, as with any foundation, it’s critical that it be strong. And when it comes to the much-more advanced needs of 21st century 3D technologies, that means much higher-performing.

The goal, Dyndrite Founder and CEO Harshil Goel told me when we spoke upon their launch, is to “gain control over the CAD to additive workflow.”

The company says the Dyndrite Accelerated Geometry Kernel (AGK) “features a multi-threaded and GPU-powered hybrid geometry core, a scalable modern computation architecture, and an accessible Python programming interface. Dyndrite’s built-in extensibility enables a variety of plug-ins for simulation, MES, OEM toolpath development, and more.”

Demonstrations of the kernel in action have shown a much speedier 3D workflow that can keep up with the faster advances the hardware segment of the 3D printing industry has experienced to date. In the digital-to-physical workflow that is 3D printing, that initial digital aspect is pretty major — putting software squarely in the spotlight.

HP 3D Printing Software Focus

HP is now a well-established player in the industrial 3D printing world. Offering both polymer and metal solutions, the heritage inkjet company is well poised to offer strong solutions across a wide range of applications.

They also understand the need for advanced software to go with those advanced hardware and material capabilities, as well as the need to do so together with the industry.

Collaboration is a major part of overall growth for a nascent industry like 3D printing. HP has been among the companies focused on collaborating, apparent in recent moves like todays’ announcement with Dyndrite and in working at the forefront of efforts in the 3MF Consortium.

Luis Baldez, 3D Printing Market Development, Senior Manager at HP, was recently appointed the new Executive Director of the 3MF Consortium, and shared his views on the importance for a sophisticated file format that best meets the complex needs of 3D printing.

So it’s also fitting to see the HP team working closely with Dyndrite.

HP x Dyndrite Strategic Partnership

HP and Dyndrite have been working together for some time, so what does this new relationship mean for them?

Today they announce “a long term licensing agreement with HP to help power their next generation cloud and edge-based digital manufacturing solutions” that will “bring unprecedented performance, efficiency, automation, and extensibility to the company’s growing portfolio of digital manufacturing products.” The focus, they say, reflects HP’s commitment to innovating in quality, performance, and automation.

Those focus areas jive nicely with the need in digital manufacturing for a more powerful manufacturing software platform.

“The promise of AM is to deliver customized, personalized, and on-demand 3D printed parts, on an industrial scale. For this to happen the AM software industry must evolve. Dyndrite’s mission has been to accelerate this change. Our collaboration with HP dramatically scales the impact our technology will have in the AM and DM industries. We appreciate the confidence they have placed in us and are energized by their vision,” said Goel.

When they say “long-term partnership” they mean it; Goel noted that he looks “forward to a long and successful partnership with HP for years to come.” Clarifying a bit of what the collaborative efforts will entail, the release explains:

“Through this new collaboration, HP and Dyndrite plan to focus on developing solutions that leverage the Dyndrite kernel to improve efficiency, enhance performance and quality, enable mass-personalization, automate complex workflows, and create scalability and extensibility for continued partner and customer innovation.”

We’ve been intrigued by the promise of the Dyndrite 3D kernel since its public introduction last year; this strong partnership will hopefully propel its potential forward into a scalable, viable additive manufacturing mainstay.