There’s one filament that appears to have the highest-temperature resistance of them all: EXTEM AMHH811F.

High-temperature resistance is a well-sought after property these days, since an increasing number of manufacturers are turning to 3D printing for components. While some components have traditionally been made with metal, it is possible to substitute polymer parts for metal if they are sufficiently strong and also have sufficient heat resistance for the specific application.

Consider the typical heat resistance (glass transition temperatures) of some common polymers as compared to metals:

- PLA: 60C

- ABS: 105C

- PEEK: 143C

- Aluminum: 227C

- Titanium: 450C

- Steel: 870C

- Tungsten: 3400C

Of course, these can vary considerably depending on the specific chemical mix involved. Sometimes the heat resistance can be higher. But you get the idea here that there is quite a range of heat resistance levels for different materials.

When designing a part one would examine the engineering properties required, including the heat resistance. Then a material is selected that fits the heat resistance level required. In the case of metals, the heat resistance of the material is often far, far above the actual thermal requirements. But metal is easy to get and so it is frequently used.

But that could be changing with the introduction of very high-temperature resistant 3D printing materials. In my previous post on this topic, I listed ten common high-temp 3D print materials. These have such a high temperature resistance that they may be able to meet the requirements for parts that have previously been produced in metal.

For example, let’s say the specifications for a part require a temperature resistance of 400C. That part clearly must be made of metal, and not aluminum, as its temperature resistance is too low.

On the other hand, say you had specifications stating a requirement for a temperature resistance of only 100C. In that case, normal PEEK material could do the job.

The advantage here is that the polymer parts are usually much lighter than the metal equivalent, yielding better performance in many applications.

Highest-Temperature Filament

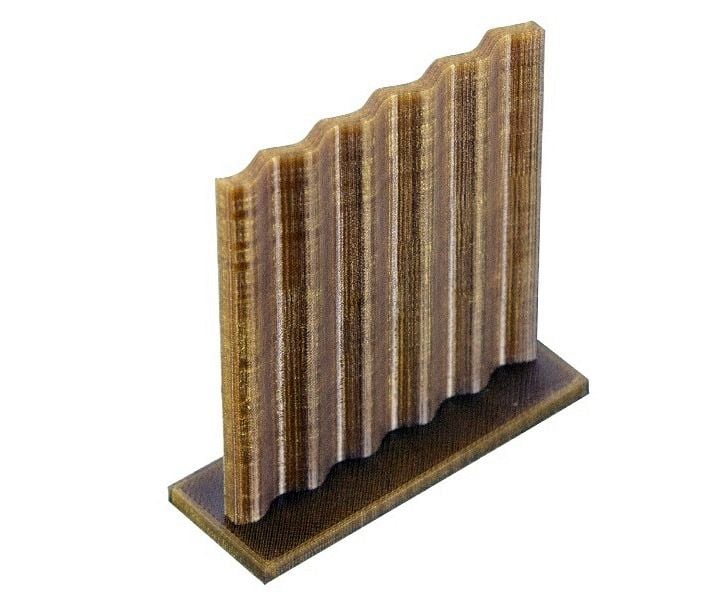

One company claims to supply the “highest heat resistance” filament material. Italy-based ROBOZE offers EXTEM AMHH811F material, produced by SABIC, that apparently has a temperature resistance of 247C. That’s far above even ULTEM, which has a glass transition temperature of around 217C.

As you can see, the higher the temperature resistance, the more possible applications can be undertaken. This EXTEM material could certainly take the place of metal parts in many cases.

Will EXTEM AMHH811F remain the highest-temperature 3D printer filament? I don’t think so, as the chemical companies may have in their vast portfolios new materials of even higher temperature resistance. We simply have not seen them yet deliver them in filament form.

Via ROBOZE