Researchers at Virginia Tech have developed an unusual method that allows latex to be 3D printed.

Latex is a very unusual material, as it is actually an emulsion of polymers and water. Wikipedia describes it as:

“Latex is a stable dispersion (emulsion) of polymer microparticles in an aqueous medium. It is found in nature, but synthetic latexes can be made by polymerizing a monomer such as styrene that has been emulsified with surfactants.”

There have been some attempts at 3D printing this unusual material in the past, but these researchers have now found a rather unusual way to do so.

The problem with latex is that it must be made into a liquid form for 3D printing, and in this state it’s very unstable. One of the researchers, mechanical engineering PhD candidate Viswanath Meenakshisundaram, explained:

“Latexes are in a state of zen. If you add anything to it, it’ll completely lose its stability and crash out.”

They overcame the problem by developing a kind of chemical “scaffold” that holds the latex in place. This stability allowed the team to mix in some photoinitators that converted the material into a liquid photopolymer.

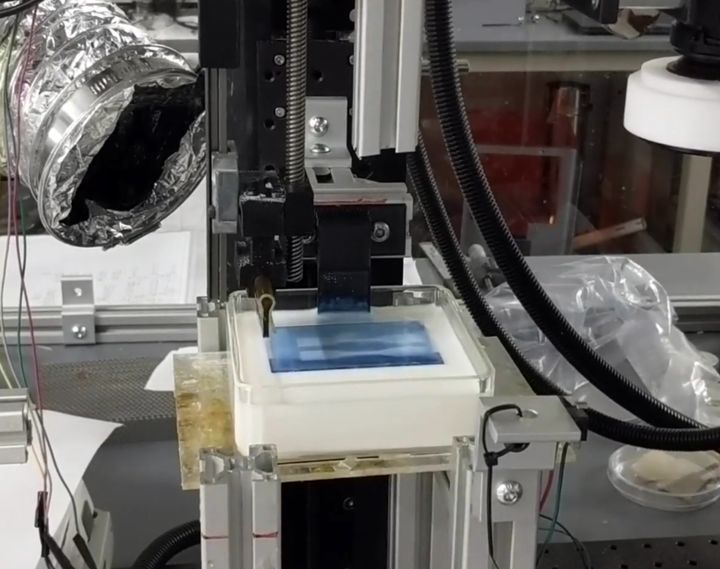

3D Printed Latex

3D printing this material proved very challenging, even though UV curing is a well-known 3D printing process. Evidently the fluid particles would tend to drift outside of the curing areas, and this corrupted the geometry of the 3D printed samples.

To overcome this unique problem they developed an intelligent optical system that monitored the UV light’s interaction with the material and made adjustments in real time. This itself is quite an interesting development that we have not seen in other 3D printing systems.

That’s not all. There was a surprise when the finished 3D printed parts were examined closely. VT explains:

“Meenakshisundaram and Scott discovered their final 3D printed latex parts exhibited strong mechanical properties in a matrix known as a semi-interpenetrating polymer network, which hadn’t been documented for elastomeric latexes in the prior literature.”

It now appears we have a practical way to 3D print strong latex objects!

Via Virginia Tech