“If you want something to stand out, the best way to do so is to light it up like a Christmas tree.”

Creators Ollie Hanton, Michael Wessely, Stefanie Mueller, Mike Fraser, and Anne Roudaut have taken this idea to heart and crafted a method to add light on any surface using a unique electroluminescent coating.

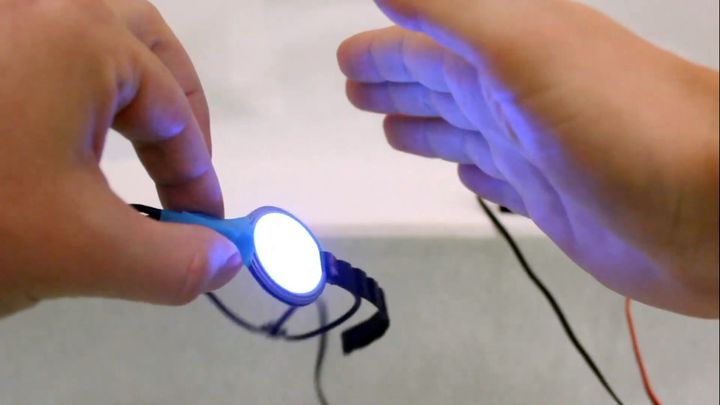

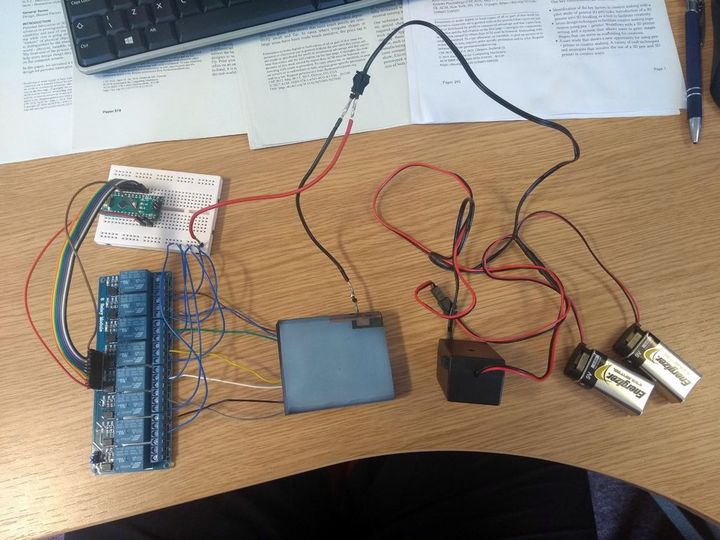

ProtoSpray combines multi-material 3D printing and the application of electroluminescent materials to create interactive touch-sensitive light displays on any shape.

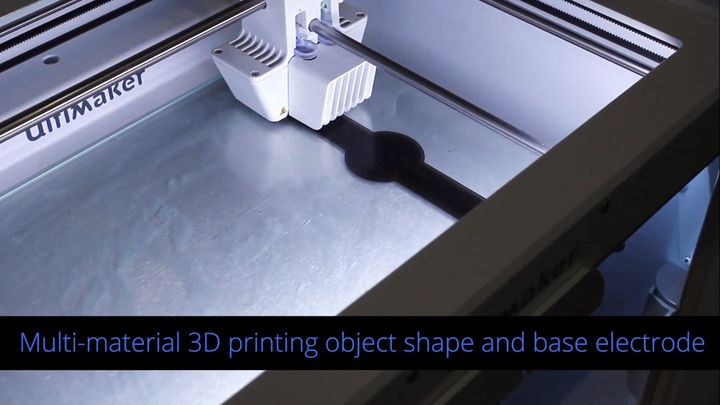

The process starts very similarly to how you would normally 3D print an object. During the design process, the base electrode area is printed with a conductive PLA (e.g. Proto-Pasta Conductive PLA), each having a thin channel where an electrode connects while the unlit substrate material is printed in an insulating PLA (e.g. Hatchbox Filament).

Once you’ve printed your multi-material model, you begin spraying the area that will be lit with three layers of electro-activating materials.

- Dielectric material layer

- Electroluminescent material layer

- Transparent conductive electrode material layer

According to Ollie Hanton’s tutorial, spray two thin coats each of PEDOT:PSS (a transparent conductive polymer), electroluminescent phosphor-based paint, and clear lacquer; making sure to give each layer ample time to dry before moving on to the next.

Read the rest at SolidSmack