An interesting experiment in metal 3D printing has resulted in some rather efficient pistons for Porsche sports cars.

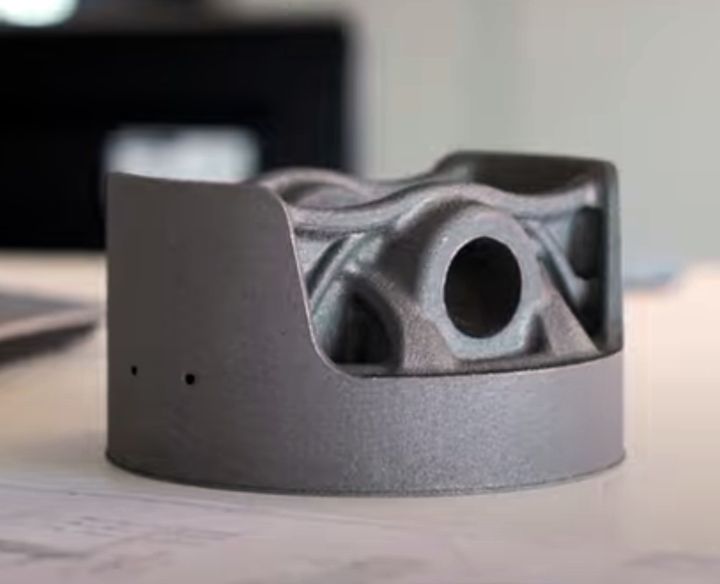

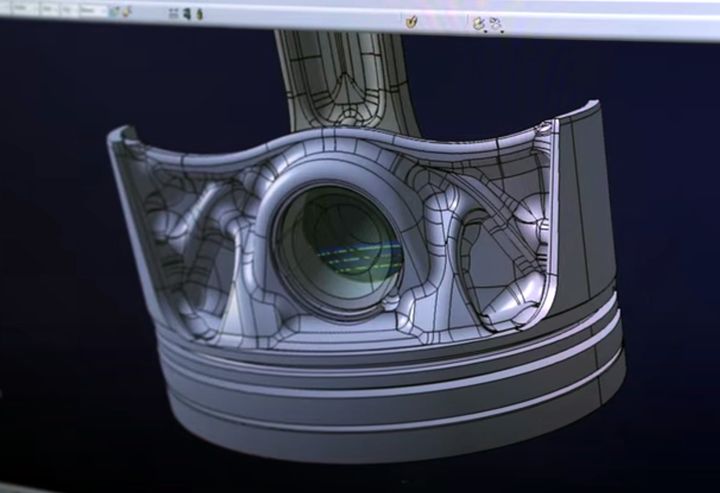

Working with Mahle and Trumpf, the team was able to produce a unique design for the experimental piston. This involved using simulation and what seems to be generative design to create a radically different geometry.

Lightweight 3D Printed Design

The new part design is more lightweight than the original design as the design was able to eliminate material where no forces were incurred. This is now becoming a standard approach in 3D printed design, where both material and weight are saved during part production, and efficiencies are had for the lifetime of the part when it is production end-use.

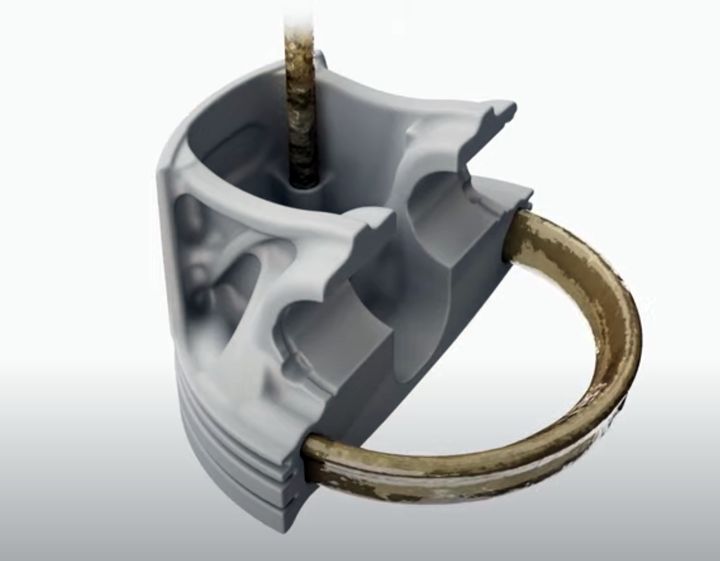

The team also made an interesting addition to this piston design: they added a cooling loop embedded under the portions of the piston that withstand the greatest amount of heat. By dropping the temperature of those areas and the overall piston weight, they were able to make the internal combustion engine more efficient.

Smoothing Metal 3D Prints

You might be wondering how a 3D printed piston could be used in an engine cylinder, as the parts that emerge from a metal 3D printer tend to have rather rough surfaces. This is true, as the 3D printed piston here was produced on a Trumpf machine that uses the standard powder bed fusion process. Due to the nature of this process, there’s always a texture to the surface of 3D printed metal parts.

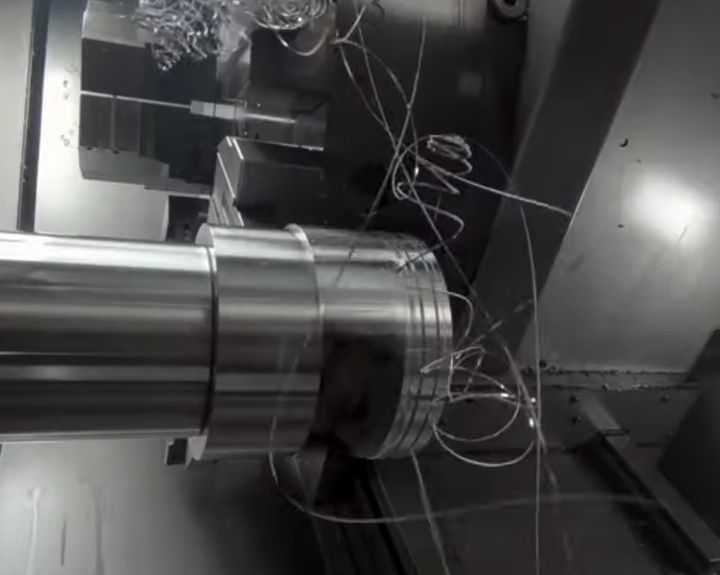

That won’t work well in an engine where there must be a tight and smooth interface between the piston and cylinder. To overcome this the development team used standard CNC milling to produce the smooth surface. In other words, the piston must have been 3D printed just a touch larger than its intended size, and the CNC mill smoothed it down to the precise size required to fit into the cylinder.

In a way, this part of the CNC milling is identical to that undergone by standard pistons, but the rest of the piston was radically different.

After undergoing a series of tests to ensure the 3D printed part would not crack under expected stresses, it was certified for testing in an actual Porsche 911 GT2 RS.

Testing revealed that the new 3D printed part was some ten percent lower in weight than the original pistons. That weight loss, combined with the new cooling circuit, allowed the 911 GT2 RS to achieve 30 additional horsepower during live testing. That’s significant, although the 911 GT2 RS already had 700 horsepower, so it’s only a 4% gain. But that 4% gain would be very significant in a competitive situation.

Leveraging 3D Printing In Industry

This project is a classic example of how 3D printing technology should be used: remake an original part design that has plateaued in performance by leveraging 3D printing and generative design technologies.

This is still a new approach for many companies, but those who do undertake a transformation will certain get a step up on their competitors.

Via TheDrive