This week’s selection is the Future Tree by a group of researchers at ETH Zurich.

The Future Tree is an abstract representation of a tree placed as a decorative canopy element at Basler & Hofmann’s office building in Esslingen, Switzerland. The process to design and build the structure involved multiple advanced technologies, including computational design, subtractive manufacturing, molding and casting, 3D printing, robotics, and assembly.

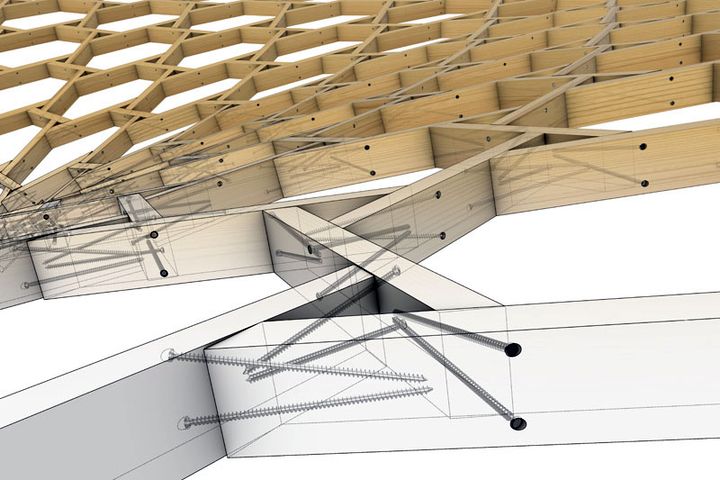

While the striking design appears straightforward at first glance, it is most definitely not. The canopy’s elements are all at unusual and precise angles to each other, while the trunk of the tree has a complex surface.

Team member Joris Burger explained to us the work required to build the Future Tree:

“The Future Tree features a concrete column which is made using an FDM 3D printed thin formwork, the first application of its kind in the built environment. It combines state-of-the-art design techniques, material science and robotic fabrication into an architectural element that spans over the courtyard of Basler & Hofmann, the client and project partner. Future Tree consists of a funnel-shaped, lightweight timber reciprocal roof structure built by a robot and a bespoke concrete column created using an ultra-thin 3D printed formwork in a process called ‘Eggshell’.”

The 3D printing portion of the project involved producing a tall hollow structure in which to hold reinforcing steel and pour the concrete mixture. In the accompanying video, you’ll see that the 3D printing was done with a Siemens robotic system that used a thick filament. I’m not quite sure what machine this is, as I haven’t seen it previously.

After the concrete cured, the builders had to remove the 3D printed formwork, which was done by softening it with a heat gun and peeling it off. I am not certain what material was used, but it’s likely a lower-temperature material like PLA, or perhaps PETG.

I wondered how the construction workers would have assembled the fantastically complex wood pieces comprising the tree canopy, but the video reveals that the placement was performed by robot!

The robot moved wood pieces to the precise position and orientation for manual attachment. This ensured the structure would truly match the original design and avoided potential mistakes that would inevitably be made if done manually. I can’t imagine what kind of approach one could use to build that canopy by hand.

This project is an excellent example of how 3D printing should really be used: as one of many tools on a complex project.