As the global pandemic continues, testing supplies remain in high demand — and 3D printing continues to step up to meet needs.

The enduring COVID-19 pandemic is still causing great strain in traditional supply chains, requiring new approaches to develop new solutions for these new problems. While in many cases 3D printing has best served as a stop-gap supply chain solution, creating products quickly but at relatively low volumes while traditional manufacturing could ramp up to mass production, some applications remain not only viable but well-served through this technology, highlighting long-term potential for 3D printing in manufacturing.

Among these, in terms of pandemic response, is the 3D printing of nasopharyngeal (NP) testing swabs. We’ve seen several companies working on this, including Formlabs, Carbon, HP, Adaptive3D, Fast Radius, and consortia that have arisen.

One interesting trend that’s now crossing oceans is that of dental providers who use 3D printing turning their resources toward creating NP swabs.

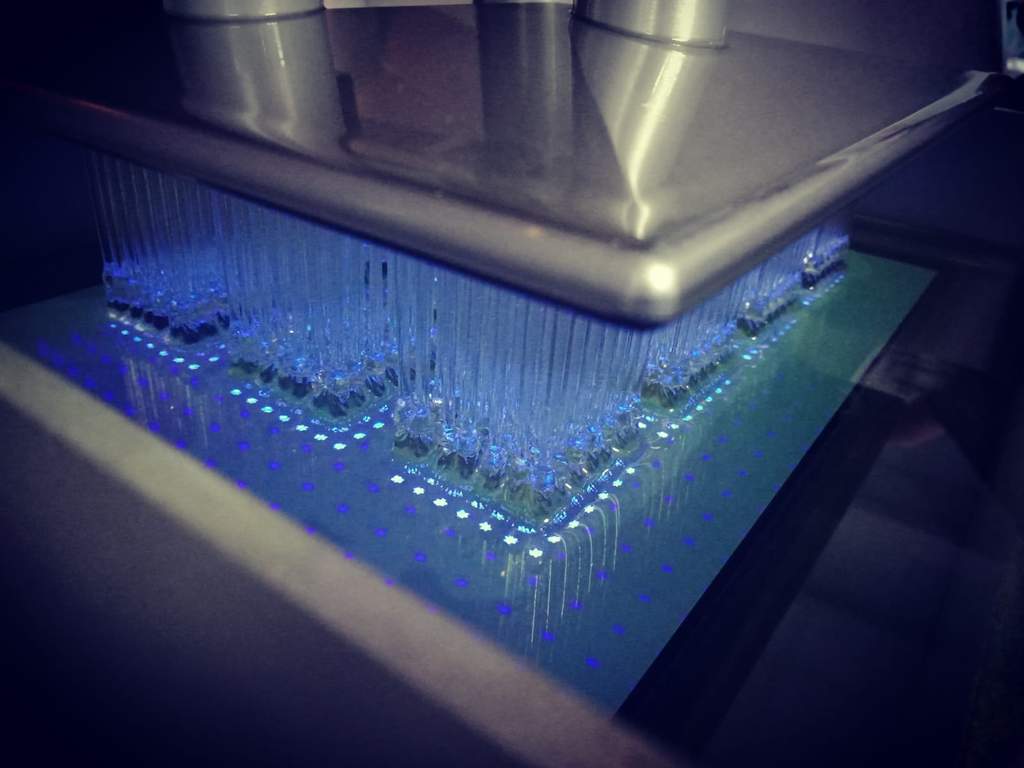

Singapore is now seeing its largest step in creating pre-sterilized NP testing swabs, as Structo is refocusing its operations, scaling up to 3D one million FDA-registered swabs weekly.

Structo 3D Printing

Structo is a 3D printing start up born out of National University of Singapore (NUS), and we generally keep up with them for insights into application-specific 3D printing for the dental industry.

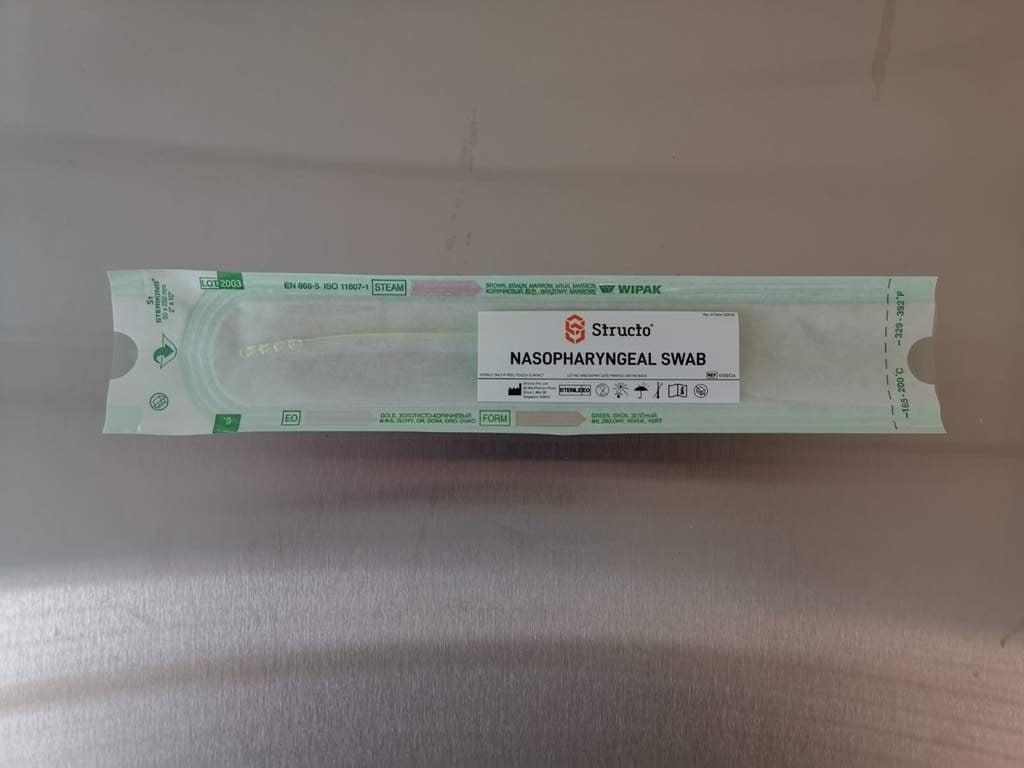

This week, though, they’ve announced a strong step in another direction, turning their 3D printing expertise to help meet demand for testing swabs. With more than a million NP swabs already produced, deliveries are starting to send the individually sterilized and packaged swabs to healthcare institutions. With deliveries beginning in Singapore, Structo will also be filling orders worldwide.

The company notes that Singapore “has deployed effective contact tracing mechanisms to curb the spread of the virus, continued large scale testing is seen as critical in allowing it to return to a state of normality.” They are very aware of the “urgent need for testing on a massive scale” on a global level, though, and note among the “heavily stricken countries” the US, Brazil, and Russia.

With Structo adding its resources to other operations serving these countries’ demand, hopefully a new supply chain is shaping up for NP swabs to help increase testing levels during this pandemic that is affecting us all.

“We have been in touch with the authorities in Singapore for several months working with doctors and hospitals to validate a number of different designs and to ensure that all the nasal swabs that we manufacture will be safe for final use on patients,” said Huub van Esbroeck, Founder of Structo.

“In this climate, we recognize the importance of the availability of testing kits and the strain that the COVID-19 pandemic has placed on the economy and supply chains worldwide. We hope that our in-house manufacturing capabilities will be able to help alleviate some of those problems and help us avoid a shortage of critical testing equipment globally.”

Structo NP Swab Manufacturing

When it comes to medical devices like NP swabs, of course due diligence must be taken to ensure that manufacturing meets (if not exceeds) standards in place.

To that end, Structo is pleasingly reassuring, as the company notes:

“Structo’s 3D printed NP testing swabs are FDA registered medical devices, which adhere to strict manufacturing guidelines. The Structo team manufactures its swabs in accordance with Struco’s ISO 13485 QMS requirements from biocompatible material and sterilizes each individually packed swab to ISO 11135 standards.”

Here’s where some of that dental experience certainly comes in handy, as the company is surely well-versed in the needs of healthcare products made well and made right.

This is also why each swab is sterilized prior to shipping, as the company is seeking to ease any burden possible on healthcare providers.

Structo notes that throughout the last few months they have been “working in collaboration with other 3D printing partners, universities and medical institutions across Singapore” to mobilize resources toward this manufacturing goal.

As they gear up to make a million testing swabs weekly, Structo is serving as yet another excellent example of both the 3D printing community stepping up to help when needed most and the viability of 3D printing as a manufacturing technology capable of meeting critical needs.

Via Structo