RIZE is introducing a new 3D printer, developed with Sindoh, that represents an interesting professional desktop composite system.

Early this year, RIZE and Sindoh announced a materials alliance focusing on RIZIUM 3D printing material. That collaboration goes deeper than perhaps we first imagined, as the two companies worked together to develop the new RIZE 2XC adaptive workplace 3D printer.

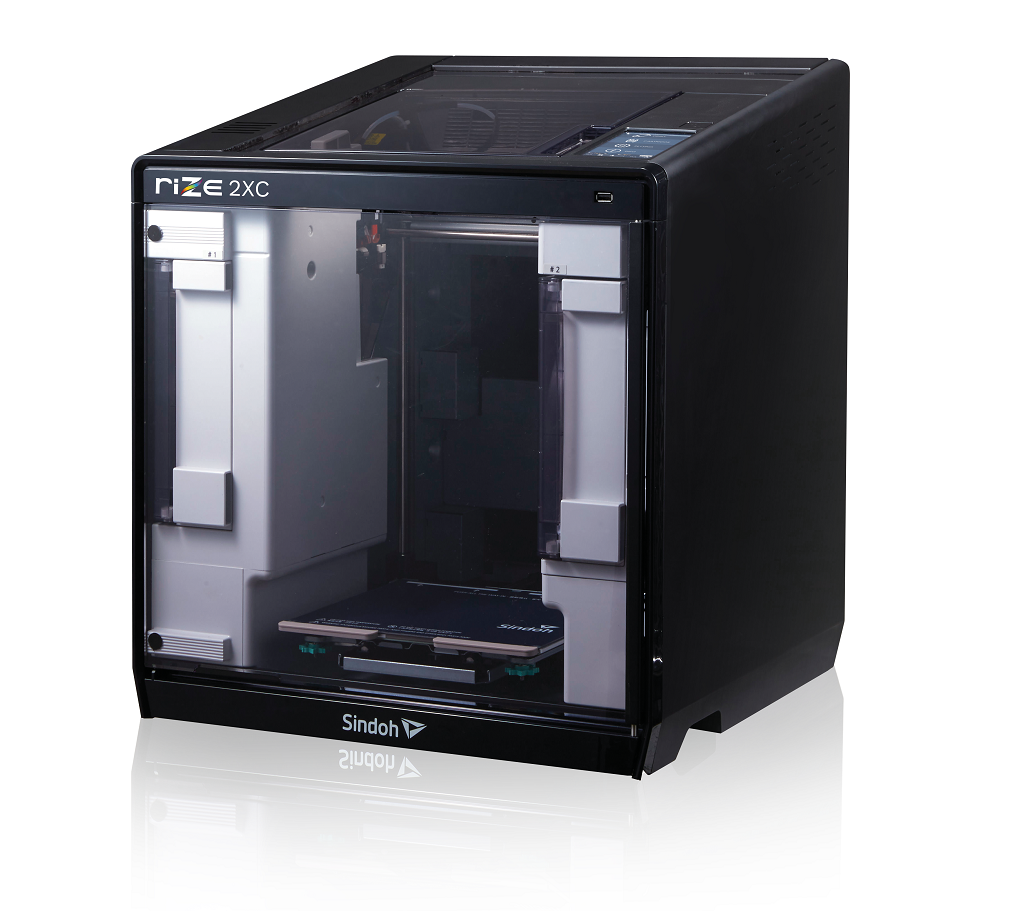

RIZE 2XC

The new 3D printer “represents the first deliverable of the RIZIUM Alliance, a collaboration between key industry partners and RIZE to drive greater safety and sustainability in 3D printing,” the announcement states.

That sentence is packed full of RIZE’s key words: alliance, collaboration, safety, sustainability — which means there’s a lot to unpack there.

We can start with the collaborative aspects here. The RIZIUM Alliance seems indeed to be an interesting strategic approach to collaborative development centered around RIZIUM composite materials.

Safety and sustainability fit neatly with RIZE’s oft-stated goals for operability of its 3D printers, messaging the company’s leadership has often underscored in our conversations.

The new 3D printer leverages expertise from both RIZE and Sindoh, using, for example, a dual-extrusion system from Sindoh that can capably handle RIZIUM engineering-grade materials. It can 3D print functional parts using “two independent extruders [that] are specifically designed for hardened materials and composite filaments,” with RIZIUM and RIZIUM Support each run through one extruder in a print to maintain the easy support removal for which RIZE originally gained attention.

The RIZE 2XC is available for order as of June 30, with an introductory price of $3,995 in the US (€3,995 in Europe).

RIZE 2XC Details

For additional detail into the new system and company updates, I spoke with RIZE President and CEO Andy Kalambi and Founder and CTO Eugene Giller.

Giller, who had the RIZE 2XC set up in his home, showed me several parts he’d been making on both it and the XRIZE system that hit the market last year.

“The printer is positioned below $5K,” he noted off the bat, and is “30-40% bigger than most printers in its class. It can use other materials, though we only ship it with RIZIUM and RIZIUM Support materials. There’s been a lot of work with Sindoh, such as for the hardened nozzles and frame.”

The machine, he said, “has a lot of cool features”:

- Onboard camera to remotely check print status

- Voice operation that can connect to Alexa

- LED lamp to light the print chamber

- SOLIDWORKS connection

- A proven platform with Sindoh hardware offering high reliability

Additional RIZE 2XC specs include:

- Nozzle diameter: 0.4mm

- Max build size: 228 x 200 x 300 mm

- Connectivity: USB, WiFi, ethernet

- Layer thickness: 0.05-0.4mm

- Filament diameter: 1.75mm

- User interface: 5” color touchscreen

- Slicer: 3DWOX Desktop Slicer, Sindoh Cloud Slicer

- Operating System: Windows 7 or above, Mac OSX 10.10 or above

Priced substantially below other RIZE 3D printers, the sub-$5K 2XC is designed to “open up lots and lots of applications” including jigs and fixtures, assembly, packaging, logistics, health and safety, quality control, and equipment, Giller noted.

Product Launch In COVID Times

One intriguing twist to the RIZE 2XC origin story is that it was engineered completely remotely, with teams in both US-based RIZE and South Korea-based Sindoh working together from their home offices.

The RIZE/Sindoh relationship was announced in mid-February, at 3DEXPERIENCE World, Kalambi noted — usually a great time for an announcement, but this year that was “right as the COVID crisis was just beginning to show itself.”

That didn’t stop the teams, though:

“Right through these COVID times, we kept working on this. When the COVID situation worsened, we moved printers to people’s homes; our entire engineering team carried one or two printers home, and we continued development work. All the products being launched now were developed in COVID times,” Kalambi said.

While everyone worked remotely, checking in virtually every morning, productivity was impressively high for RIZE as the team both made PPE including face shields for pandemic response and continued engineering projects as planned.

“We discovered not just that we created a printer, but we also discovered the value of true safety,” Kalambi continued of the development of the RIZE 2XC. “These machines are installed in people’s homes, offices, even kitchens, we have kids going around; one of our lead scientists even had a baby during this time. We discovered a new way of working, and said that had it not been for the safety of our materials and zero-emissions approach and recyclability, we never would have been able to do it.”

This experience reinforced the RIZE perspective of a true adaptive workplace, especially due to the international remote collaboration required from both RIZE and Sindoh to see the new machine come to fruition.

My catch-up with Kalambi and Giller also offered interesting insights into more that we can expect to see from RIZE in the coming months; stay tuned for more from the conversation.

Via RIZE