Manufacturing in space is reshaping in a series of acquisitions.

Meet Redwire, a newly formed company describing itself as “a new leader in mission critical space solutions and high reliability components for the next generation space economy.” While such statements often sound like a familiar ambition of a young venture, Redwire is already able to back that claim up, as the venture has taken shape through a series of acquisitions — most notably, and most recently, including Made In Space.

Redwire Launch

The official launch of Redwire was June 1, 2020, when the company emerged as a combination of two recent acquisitions from AE Industrial Partners (AEI): Adcole Space and Deep Space Systems (DSS).

So while Redwire has officially existed for less than a month, its roots go back decades. Adcole Space was established in 1957, and DSS in 2001. For its part, AEI is described as “a private equity firm specializing in Aerospace, Defense & Government Services, Power Generation, and Specialty Industrial markets,” offering that specialized business expertise along with the space heritage of the companies that became Redwire.

Adcole Space’s focus in space exploration has included satellite components and experience in missions to Mercury, Mars, Jupiter, Saturn, and Pluto. DSS’ portfolio includes “integrated spacecraft, fully qualified payloads, spacecraft elements, data acquisition and recovery systems, ground support equipment and embedded software,” with team experience on projects from the International Space Station to Orion and Dream Chaser, as well as “several large classified programs.”

Bringing these companies together to form Redwire, AEI is hoping to create a new leader in space exploration.

“Combining DSS with Adcole Space to form Redwire will provide opportunities for current employees of DSS to contribute and build a truly one of a kind space company with unlimited potential. The combination of our businesses will enable us to offer our customers a one-stop shop for complex space exploration products and services,” said Steve Bailey, President of DSS.

Redwire Acquires Made In Space

Redwire is already, three weeks into its formal existence, expanding.

Today, the company announced the acquisition of space manufacturing company Made In Space (MIS).

Made In Space may sound familiar, as the company has since its founding in 2010 focused on on-orbit space manufacturing technologies — including 3D printing. The company put a 3D printer on the International Space Station (ISS) in 2014, allowing astronauts to 3D print a wrench shortly after realizing they both needed and lacked one, and has been looking larger with the massive Archinaut project that received millions in funding from NASA.

MIS has certainly proven the viability of 3D printing in space.

And now they’re joining the Redwire team through this acquisition, for which terms were not disclosed.

The acquisition includes MIS’ Florida HQ, offices in Alabama, California, and Ohio, and its sister company based in Luxembourg, Made In Space Europe.

Redwire Operations

For now, it seems, MIS and the other Redwire-acquired companies will operate relatively independently.

SpaceNews reports that these teams will continue to do their own work — MIS will continue work on Archinaut, for example — though “over time they will combine under the Redwire name” as they “leverage the capabilities of other Redwire companies.”

MIS President and CEO Andrew Rush will, SpaceNews indicates, become the Redwire COO, and MIS Chief Engineer Mike Snyder will become Redwire’s CTO.

Further acquisitions are also likely as Redwire looks to truly build out a unique, leading space in the space industry.

The ability to ‘leverage the capabilities’ of other experienced teams will help these previously small, independent operations scale up their work and gain access to new technologies and areas of expertise — which is often one of the major benefits to major M&A activity. Combining it all under the Redwire umbrella offers an integrated approach for a greater common goal, which is both exciting (space!) and a business strategy driving toward profit.

“To truly realize the full potential for space exploration, innovation must change the economics. Made In Space has been driving these innovations and is now positioned to revolutionize the industry,” said Peter Cannito, CEO of Redwire.

The Economics Of Space

I must confess that, as more of an idealist than an investor, I tend to think of space exploration with starry eyes and haven’t given much thought to the space economy.

But the space economy is a very real thing, and the companies looking toward a future of in-space manufacturing aren’t doing so purely because it’s cool. (Even though it is.)

A blog post from MIS this week is titled, “How In-Space Manufacturing Will Impact the Global Space Economy,” and focuses on that global space economy. It discusses — interspersed with snippets of Andrew Rush’s Keynote at the International Symposium for Personal and Commercial Spaceflight titled “Manufacturing in space: Reshaping the Landscape of Space Commercialization” — both the technologies and their financial impact.

Some of this sounds similar to how we often discuss the benefits of additive manufacturing and other next-gen tech, as they write:

“This new era of space depends on emergent technology that enables us to go farther and stay longer. Capabilities that maximize efficiency, sustainability, lower cost, and make the most of the space environment. In-space robotic manufacturing and assembly, by which structures for space can be built in space instead of on Earth, has been recognized as one of these emergent technologies that will have transformational effects on both our ability to maintain a sustained presence in space and the health of the global space economy. In-space manufacturing will lower the cost of launching and operating in space and enable new capabilities to those conducting business and research in low Earth orbit, the Moon, and beyond.”

But then they move into how the next step in creating a beyond-Earth sustained human presence is making space profitable through in-space manufacturing and assembly. Their work, essentially, “provides an economic motivator to accelerate space exploration.”

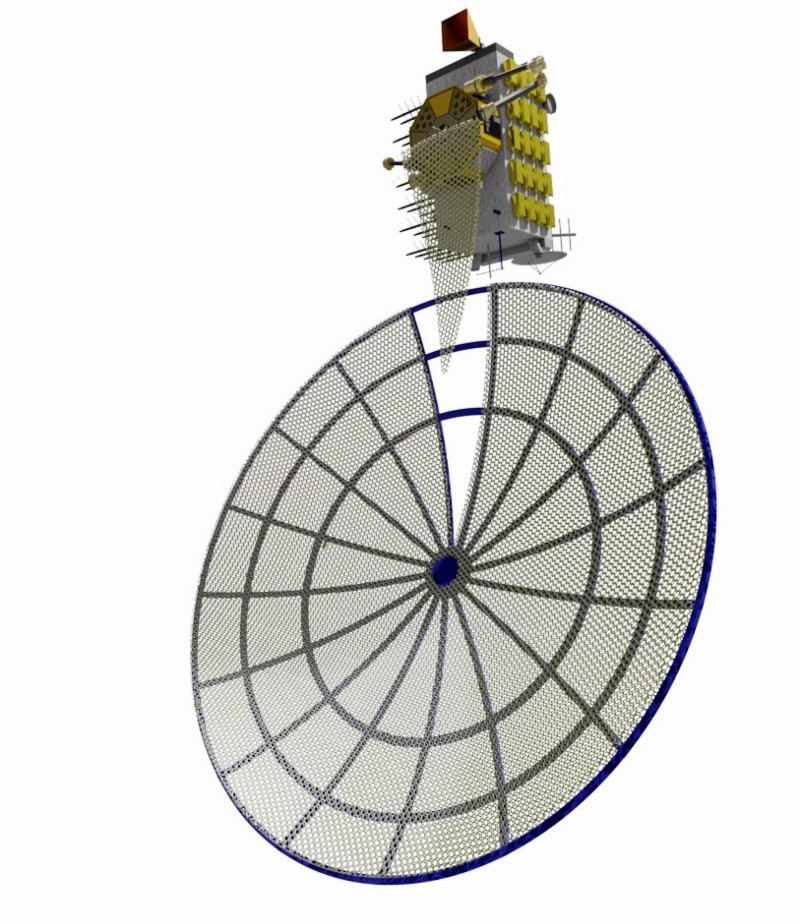

Certainly humanity has always reached toward the stars, and certainly there are realities that have forestalled many efforts. As technological hurdles are increasingly able to be overcome — just look at the Archinaut, which MIS describes as “the world’s first satellite to manufacture and assemble portions of itself” as it 3D prints in low-Earth orbit — another challenge is that all-important bottom line.

Making space affordable through privatization (think of the recent SpaceX launch, the first such commercial effort with astronauts on board) and through these advanced technologies (e.g., 3D printing lighter weight structures and more efficient rocket engines) is opening it up to more exploration. But even then, that isn’t cheap. There needs to be “something in it” for the investors shelling out the millions of dollars required.

So the forming of a new, integrated space exploration company makes a lot of sense. Bringing together these teams and their portfolios isn’t just a way to accelerate development — it’s a way to speed toward the path toward making space exploration profitable.

Via Made In Space, Redwire, and SpaceNews