Henkel is adding to its Additive Manufacturing Services.

Henkel isn’t just a big company — it’s rather huge, all things considered. The company employs 52,000 around the world and among some of the best-known products in its portfolio are Schwarzkopf hair care; Dial soaps; Right Guard antiperspirants; Persil, Purex, and all laundry detergents; and Snuggle fabric softeners. Their adhesives business is where 3D printing comes in, though, as we look to brands including Loctite.

When Loctite entered into 3D printing with new resins, it initially seemed surprising. It makes sense, though, as polymer science expertise was already well established and they made the strategic decision to leverage that know-how into another opportunity.

And since that launch, Henkel has just been upping its game in 3D printing, introducing new materials and establishing materials partnerships with industry participants.

Henkel Expands Additive Manufacturing Services

And now the company is again putting its resources to work in broadening its 3D printing offerings.

Interestingly, participation isn’t just in materials development, as Henkel also offers Additive Manufacturing Services — and today they announce the expansion of those services.

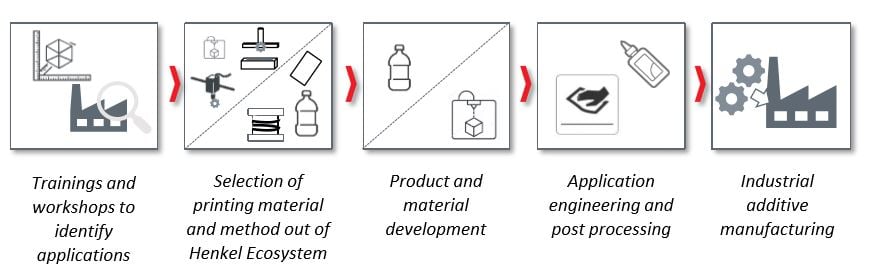

Henkel offers Engineering and Production Services for Additive Manufacturing that are actually rather extensive. Bear with me for this bullet list:

- AM Trainings and Workshops

- Part Identification

- Printability Assessment

- Model Design

- Mechanical Simulation

- Computational Optimization

- Print Job Evaluation

- Prototyping / Pre-series Production

- Customized Test Plans for Validation

- Quality Control Plan (QCP) Development

- Post-Processing for Enhanced Performance

- Final Parts Production

Today’s announcement indicates primary focus for customers in automotive and industrial areas, as Henkel will “provide support with 3D printable materials, from design through to final part manufacturing.”

Remember the note above that Henkel is itself quite large? That means there’s an established infrastructure to leverage here, and that’s exactly what the company is doing. Henkel explains of its application centers and certified plant in Missouri (“which is already supplying millions of traditionally produced parts to a host of automotive and industrial customers”) that:

“These facilities meet and exceed exacting industrial standards including: OHSA 18001:2007, ISO/TS 16949:2006, EMS ISO 14001:2015 and ISO 9001:2015. Henkel Additive Manufacturing Services offers a wide range of 3D printing capabilities including stereolithography, digital light processing, and multijet fusion, in addition to dedicated post-processing and finishing services.”

That’s an interesting list of 3D printing technologies, as well; SLA and DLP fit neatly with previous Henkel announcements, especially as a resin producer. But Multi Jet Fusion? Back in 2018 Henkel was announced as the “first global reseller of HP Multi Jet Fusion 3D printers” and there’s a longstanding relationship there. That reseller relationship, in fact, built on collaboration that started (naturally) in materials.

There also remains overlap with Shapeways, as in November the two companies introduced their partnership for industrial large-scale additive manufacturing. Looking into the services page from Loctite, for example, directs to a Shapeways site for sample part availability.

Henkel Additive Manufacturing Services is looking to build quite a strong offering indeed, and that comes from both product portfolio and expertise. Truly understanding the interplay between these factors is the only way to introduce the reliable, repeatable results necessary for true industrial serial production. And it sounds like this team is well aware of all of this.

“Knowledge of materials, and additive manufacturing workflows are critically important to the future success of 3D printing in a production environment. Equally important, and often overlooked is a knowledge of industrial customer requirement, APQP, exacting customer quality requirements, and seamless part ordering and delivery. Failure to control and manage all these factors can lead to a breakdown in customer supply chain. Henkel’s long history in producing and delivering traditionally manufactured parts as a Tier 1 to multiple industries, coupled with exciting material development in additive manufacturing is a powerful combination to lead the development of the production of reliable end use parts,” says Chris Liddiard, Market Segment Head Automotive and Industrial Parts.

3D Printing Strategies

Many large companies are examining their industrial 3D printing strategies these days.

In many cases, chemicals companies and other businesses focusing on materials science are doubling down on their investment into 3D printing. Sometimes, though, that doesn’t work out, as we saw with the recent announcement of DSM acquiring part of Clariant’s 3D printing portfolio after Clariant noted that these operations didn’t jive with its strategies.

For Henkel, it seems to be a pretty obvious focal fit as the company continues to examine additional ways to participate in the industrialization of additive manufacturing.

Materials absolutely play a massive role in the capabilities of additive manufacturing to be considered “industrial” and used as a technology suite for end-use products. Building upon that established expertise to offer end-to-end services is a strong move, and it seems clear we should expect to hear much more from Henkel and its Additive Manufacturing Services.