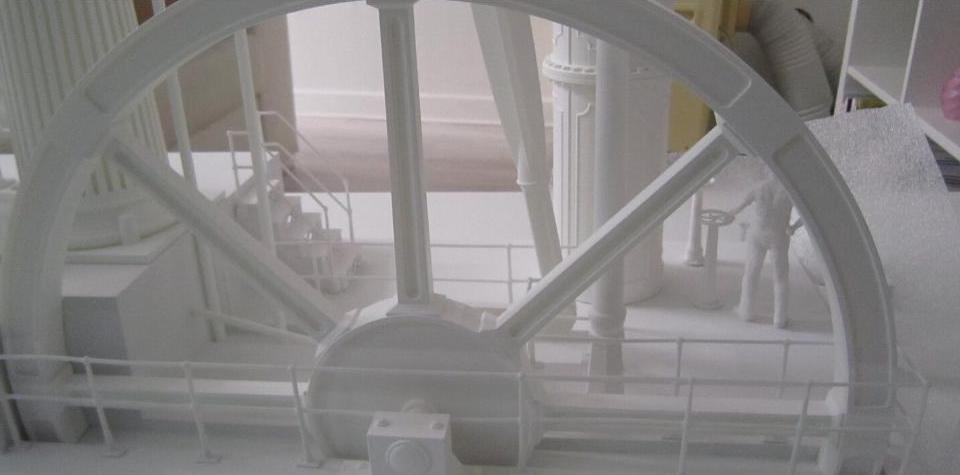

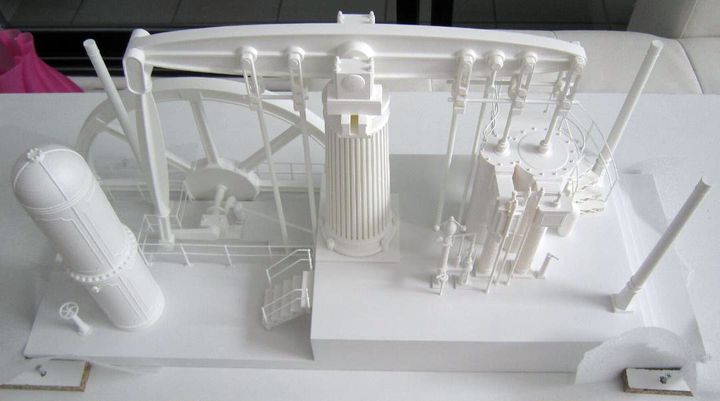

This week’s selection is the Old Steam Engine by Dijon 3D.

Dijon 3D is a French 3D print reseller and service provider, based near Dijon. They began operations in 2016 and today sell equipment from Zortrax, Creality, Volumic and other 3D printer manufacturers, along with 3D scanners from Shining 3D. They also provide consumables, materials, parts and service on 3D equipment.

I’d say they are a typical regional provider of 3D capabilities to nearby companies using 3D printing in professional disciplines.

The 3D model they’ve produced here is quite interesting from both a design and a 3D printing standpoint.

It was produced for Voies Navigables de France (“Navigable Ways of France”), an organization dedicated to promoting the use of river travel in that country. VNF provides services such as notices to boat captains, computing river travel routes, mapping anchorages, managing water resources and much more.

The 3D model for this print was developed by Dijon 3D, simply sourced from historical photographs of a steam engine. Dijon 3D modelers used the images to create all the components in the full 3D model in CAD.

The 3D print of the model is actually quite large: 750 x 250 x 400 mm, and as you might guess, it’s made from multiple parts.

What’s interesting is that the print is composed of parts made on different 3D printing processes. Dijon 3D explained they used FDM, SLS and SLA processes to produce the components, likely using the “best tool for the job” approach.

This is quite instructive, as we often forget that different 3D printing processes are each good and bad for different 3D model scenarios. We usually attempt to 3D print the whole object using a single job and thus one particular 3D printing process, but that’s not always the best approach.

Here Dijon 3D deconstructed the object into parts that are each best made using a specific 3D printing process. That’s something we should all consider doing more, particularly for complex 3D models such as this Steam Engine.

Via LinkedIn (Français) and Dijon 3D