Researchers have developed a new method of cutting tiny 2D materials, but could this be the foundation of a new type of 3D printer?

The research, undertaken by EPFL, developed a method of cutting nano-layers. They explain:

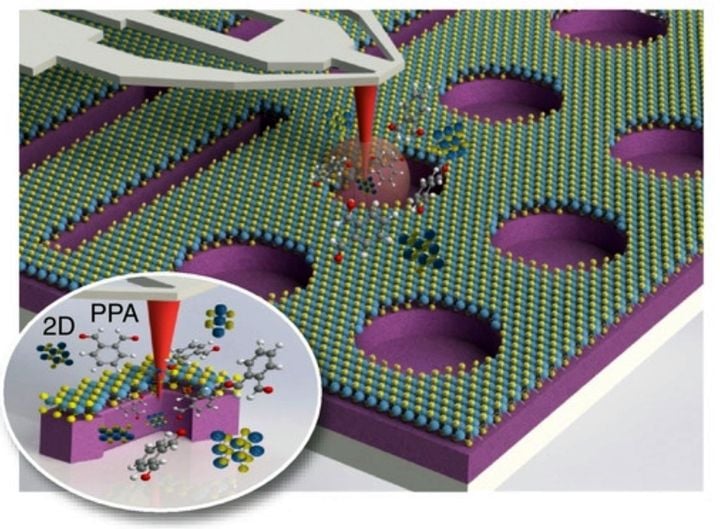

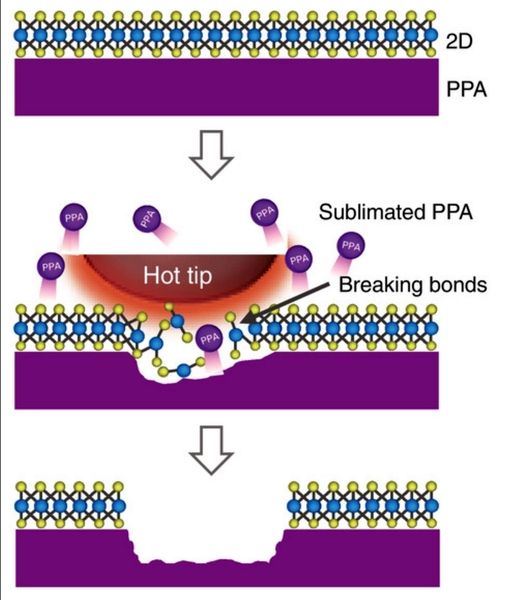

”Herein, we have demonstrated a high‐resolution one‐step nanolithography process for the direct nanocutting of 2D materials. Our approach is based on the use of a nanoscale hot tip that induces the rapid sublimation or plastic deformation of a polymeric layer and results in the breaking or stretching of the supported 2D materials.”

The “hot tip” is an extremely fine device that is heated in their experiments to near 150C. At this temperature the “polymer chains break and simultaneously unzip into small volatile molecules.” In other words, the material turned into a gas, leaving a gap where it once was solid.

3D Nano-cutting?

While this technology was developed for 2D applications, specifically for chip-making lithography, I am wondering about the potential for using it as a 3D printing technology.

Most 3D printing processes are a layer-by-layer affair, where material is deposited using some mechanism to form whole objects. However, in a couple of cases this layer-by-layer approach was done using subtractive rather than additive methods.

One long-expired system was called the Solido. It was a system that used plastic sheets. A sheet would be loaded into the build chamber, where it would be glued to the previous layer, but also cut along the edges by a computer-controlled blade. After printing the excess plastic would be removed.

Another example of this approach was used by the now-defunct MCOR Technologies equipment, which used a similar approach, except instead of plastic sheets, plain paper was used. Later versions of their systems used paper rolls, rather than individual sheets, for higher speed.

While both of these companies are now gone, the concept of laminating sheets was proven to work for 3D printing. What we have with this research is a new type of blade that could potentially be used in such a system.

I think the key to this concept would involve the materials, as you would need to determine a material that is not only cuttable by a form of nanotip, but also a material that could be laminated together, layer-by-layer. Otherwise the 3D printing process would be similar to both Solidio and MCOR Technologies’ systems.

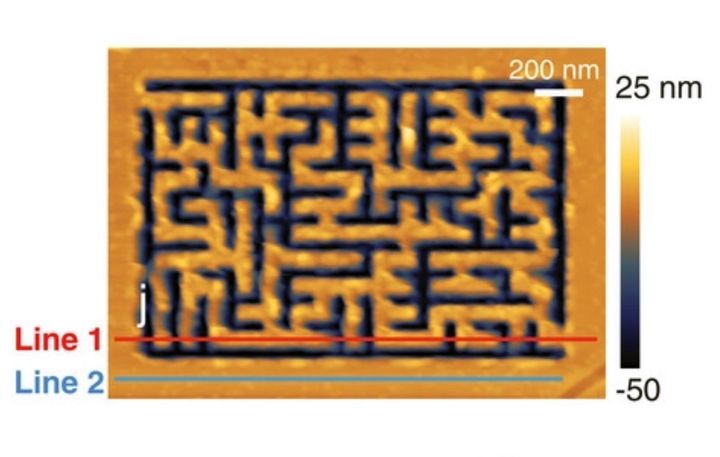

I am not aware of any company pursuing this method, and maybe that means it’s been evaluated and is fruitless. However, if it did work one could expect to see objects with nano-scale resolution appear, as the examples above show a resolution many times typical 3D printing capability.

More than likely this hypothetical device would be used to produce smaller objects, but ones of very high complexity. That in itself is another challenge: if you could make such small objects, what would they be? We may not even have applications for this technology yet.

Via Wiley