New research has demonstrated an inexpensive method of reliably producing different color shades during SLS 3D printing.

SLS 3D printing, if you’re not familiar, is the process of selectively fusing thermoplastic particles on a flat bed of powder with a laser. By repeated applications of powder layers and fusing, full 3D objects can be built layer by layer.

Color In SLS 3D Printing

Color is not normally a part of the SLS process. Typically items are 3D printed in a monochrome material, usually white or black nylons, and then dyed afterwards (well, the white prints, at least).

This process has given rise to a number of dyeing solutions provided by several vendors that allow a manufacturer to reliably produce 3D printed items in exact matching colors.

There is no practical way to produce colors during SLS 3D printing, aside from informal experiments in which laser power is varied to toast the particles in a different way that sometimes results in “two tone” 3D prints. But that’s not really a proper way to produce colors reliably.

Even worse, by playing with the laser power you risk subverting the geometry and strength of the part, as the laser’s prime function is to fuse the particles together, not make colors.

If only there was a way to do this.

Color SLS 3D Printing

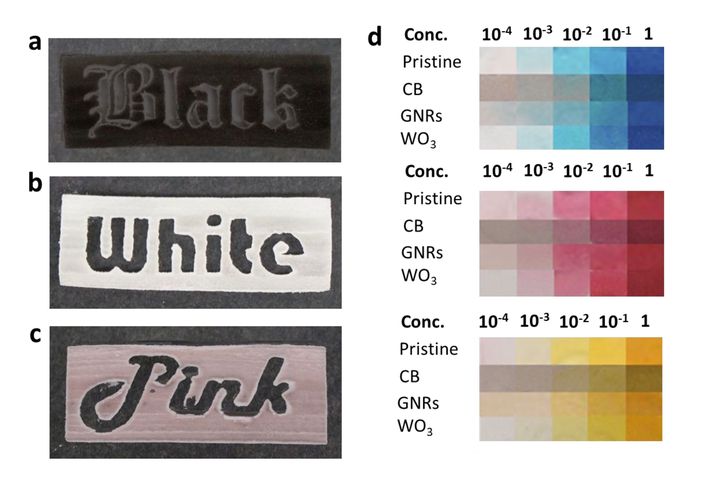

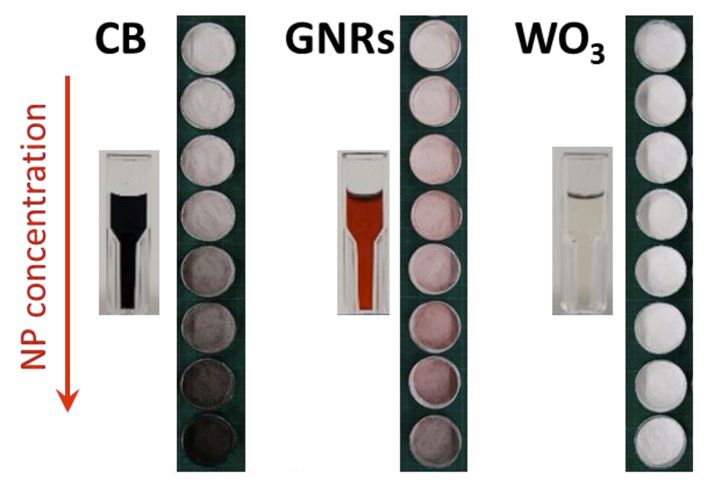

Researchers from Barcelona’s Institut de Ciències Fotòniques found a way to develop colors by including programmable photochromic particles with normal SLS powders. They used a tungsten oxide material that can be activated through exposure to UV light. When active these particles exhibit strong infrared absorption properties, meaning they absorb significantly more laser energy in a given time.

The researchers found that by varying the exposure, energy and ratio of particles they could produce a variety of color shades with great precision and reliability. They say:

“In conclusion we have demonstrated that the use of photochromic tungsten oxide nanoparticles as a photothermal sensitizer has the potential to revolutionize high color quality 3D printing. WO3 particles are easy and cheap to manufacture, show fast activation times, and demonstrate a heating- to-colour-change ratio far superior to other available sensitizers. When added to coloured inks, WO3 reproduces even very pale shades perfectly in comparison to pristine powders. This work opens the door to a whole new class of nanomaterials for advanced manufacturing.”

If this is true, we could see a new style of SLS 3D printers and materials that can provide a variety of different colorations. However, it is not likely they would be able to reproduce accurate colors, such as the Pantone set, which is something other 3D printing processes can already achieve.

But you have to start somewhere.

Via ACS

1 comment