![Copper metal 3D printed parts [Source: Markforged]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050a52dfbc.jpg)

Markforged announced a surprise new material for their Metal X system: Copper.

Copper is a highly desirable material for a number of reasons, not the least of which are very high thermal transmission and high electrical conductivity. It’s used in plenty of machines for many purposes.

3D Printing Copper

![Pure copper [Source: Wikipedia ]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050a593c8c.jpg)

Unfortunately, it’s been a terrible material for 3D printing. The most popular metal 3D printing process, powder bed fusion, involves blasting a powerful laser at a flat bed of powder that instantly creates a tiny meltpool at the laser focus. This meltpool is moved around the bed to gradually build up the solid metal object.

The key to 3D printing in this way is the laser power: by quickly melting the powder the meltpool can move swiftly and overall 3D print time will decrease. However, with copper metal there’s a big problem: thermal conductivity.

When lasering copper its heat transmissions are so high that the meltpool leaks into surrounding areas and messes up the resolution of the build. It’s ironic that one of copper’s best properties is also its undoing in this form of 3D printing.

Some have attempted to overcome this problem by introducing other materials into the mix to make it easier to 3D print copper, but the end-parts produced are said to be “less than copper” in terms of engineering properties, and that’s what it’s all about.

Markforged Copper

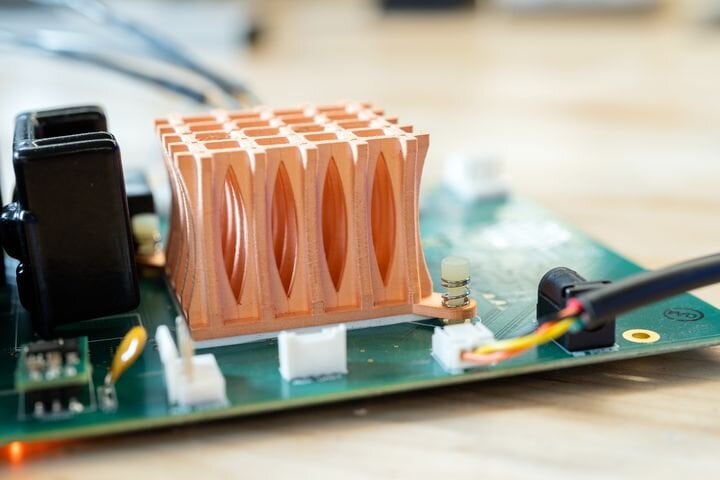

![A fine 3D printed copper heatsink [Source: Markforged]](https://fabbaloo.com/wp-content/uploads/2020/05/copper-heatsink-7_img_5eb050a5eb3ff.jpg)

Markforged has introduced a new material for their Metal X system that they say is “pure copper”. I’m not sure how they accomplish this, as their 3D printing process involves a filament containing a binder to hold together loose metal particles, copper in this case. Post processing steps are undertaken to remove the binder, and then sinter the metal particles into a solid object.

Based on their claim, it’s likely that they have developed a binder that can be 100% removed by their post processing steps, leaving only pure copper for the final part. They don’t say, but it’s possible this may have to be done in their associated Wash-1 station that is used to debind and dry freshly 3D printed parts.

The ability to 3D print pure copper parts is somewhat rare in the world of 3D printing. The only other option I’ve seen is Spee3D’s supersonic method, which produces larger parts with relatively coarse surfaces.

Markforged worked with some automotive clients to test the new copper material, and found great success. Evidently automotive manufacturing requires the use of copper spot welding shanks, which are quite difficult to manufacture conventionally.

The new copper capability allowed the automotive users to speed up shank delivery by 12X and reduced the cost of the shanks by 6X. Both are notable figures and the clients were correspondingly pleased, particularly when testing revealed the Markforged-produced parts met all thermal and electrical requirements.

Markforged Materials

The relatively inexpensive Markforged Metal X system now gains another material to add to its portfolio, which also includes: 17-4 PH Stainless Steel, H13 Tool Steel, A2 Tool Steel, D2 Tool Steel, and Inconel 625. There are two other materials apparently under development by Markforged that we may expect to see appear later this year: 316L Stainless Steel and Titanium Ti6Al4V.

Together, these form a powerful array of metals with which Markforged Metal X operators can produce geometrically interesting parts for use in many industries.

Via Markforged