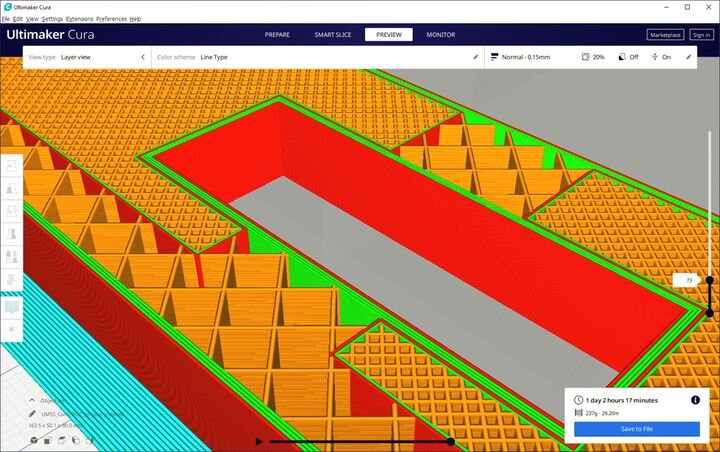

![Optimized 3D model slice in Ultimaker Cura by Smart Slice [Source: Teton Simulation]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb05090d8ead.jpg)

I had a long chat with the nice folks from Teton Simulation this week and learned quite a bit more about their upcoming product.

As you might gather from their company name, “Simulation” is their game. Simulation has long been around the 3D printing universe, as it is a way to optimize the strength of a part. Using a mathematical process known as Finite Element Analysis, simulations can show what regions of a part undergo the most stress, and therefore suggest where parts require strengthening.

This is a very common practice in 3D printing these days, but there is a big problem: virtually all of the FEA simulation products are separate software tools.

The implication is that there is a serious 3D printing workflow disruption. While the separate FEA tool can absolutely identify what areas require additional strength, it is up to the 3D printer operator to persuade the slicing tool to implement said recommendations. Typically, this is done manually.

And iteratively.

Strengthening A 3D Printed Part

How does the 3D printer operator know that they have achieved the optimum slicing configuration for that part? They don’t. They have to literally 3D print their manually devised configuration and then give it a test. If it doesn’t quite work, they have to go back to the slicing program and try something else to achieve the required strengthening.

According to Teton Simulation, this can often result in as many as 50 iterations to get the part correct. And it’s not just on end-use parts; they have found that even jigs and fixtures used in a manufacturing environment must meet strength requirements in order to perform their job on the production line.

These lengthy iteration cycles pose a barrier to 3D print adoption. They take considerably more time to achieve than one might expect, and especially because of the often long durations of 3D print jobs. Each iteration could take a day or more to complete.

Teton Simulation wants to break that cycle by injecting the FEA smarts directly into the slicing program itself. In this way the slicer can, in theory, automatically generate the optimum strengthening maneuvers directly without the need for iterations to discover them.

Teton In Cura

![Defining mechanical forces in Ultimaker Cura with Smart Slice [Source: Teton Simulation]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050912508d.jpg)

Teton Simulations’s first implementation of this concept has been achieved, and I’ve seen it work myself. They have integrated their intelligent slicing system into Ultimaker Cura by means of the tool’s plug-in architecture, and they’re calling it “Smart Slice for Cura”. Ultimately this would result in Teton Simulation providing the functionality through the Ultimaker Cura Marketplace.

The workflow is quite different when using this system. While in Ultimaker Cura you import your 3D model as usual, you can then perform an “in-Cura” FEA step. Here you can see how a part has mechanical forces defined upon it.

![Examining FEA in Ultimaker Cura with Smart Slice [Source: Teton Simulation]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0509159c20.jpg)

Once configured, the operator need only push the “validate” button to send the configuration to Teton Simulation’s cloud system to run the analysis. We’re told that this step can take some time depending on the nature and complexity of the part and forces acting upon it. For simple parts it could take 5-10 minutes, but for complex scenarios with many polygons it could be several hours.

While that could seem to be a long time to wait, it’s far, far shorter than performing iterative 3D prints and thus is of great value.

What happens to next? When the analysis is complete, the Smart Slice software tweaks a number of 3D model slicing parameters that affect part strength, including number of perimeter walls, infill density, etc. Their goal is to optimize for strength while minimizing print time.

What’s totally interesting here is that they can set up different regions within the 3D model to apply different amounts of added strength using a modifier mesh. If you look at the image at top you’ll see a cross-section of a sliced object of this type. There are multiple regions where the infill density varies.

What did the 3D printer operator do to achieve this sophisticated slice? They merely pressed the “validate” button. The rest, although not quite immediate, is done by Teton Simulation in the cloud.

As far as I can tell, this is a very significant workflow advantage that would easily speed up finalizing production 3D prints, save material and especially engineer and operator time. This seems to be the correct way to do 3D print workflow: design, analyze, optimize, slice, and print.

Teton Simulation in Other Slicers

At this point we are told Smart Slice is only built for Ultimaker Cura. That’s quite understandable, as that software is freely available as an open source project, and also has APIs and integrations available to connect Smart Slice to the main software.

However, that’s not the case for most other slicing software. Aside from Simplify3D, Slic3r and KISSlicer, most slicing programs are more-or-less dedicated to a particular vendors’ printers. For example, you use GrabCAD for Stratasys equipment, and 3DWOX Desktop for Sindoh devices. Typically these software tools are designed as closed systems, which could make it quite challenging for Teton Simulation to integrate their functionality.

I suspect that Teton Simulation is working behind the scenes with several of these players to determine how best to integrate Smart Slice. This is such a powerful option that it would be in any vendor’s interest to find a way to make it happen; if their competitor is able to do this, they must also offer it.

However, it would seem that Ultimaker Cura-based systems may have an advantage here, at least initially, since Teton Simulation has built the system already.

Teton Simulation Cost

Finally, there’s the question of cost. I asked Teton Simulation about their monetization plans and they suggested that it would be priced via monthly subscription. You would pay a monthly fee and then be able to run (probably) unlimited Smart Slice operations. But they have not yet set a price for the subscription fee.

Via Teton Simulation