![Additive Flow has unveiled a new generative design tool for additive manufacturing [Source: Additive Flow]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050855a3af.jpg)

While the hardware technology of 3D printing continues to increase, there has also been a boost in the capabilities of related software.

In recent months I’ve seen several companies attack the problems of 3D model design and optimization. This is part of the ongoing shift from prototyping to production quality parts, as prototypers quickly discovered that the parts made by the initial modeling and slicing software wasn’t optimal.

By “optimal”, I mean that the parts produced should have the maximum strength by using the least amount of material. This not only saves on the cost of material, but also on the cost of printing as less material usually means quicker prints.

The multiple approaches to solving this dilemma usually involve Ai or machine learning methods that can solve design problems far faster than humans could, and with better results. Most systems involve the human designer inputting a set of constraints around the functionality required, and the systems will then generate a suitable 3D model to meet those requirements.

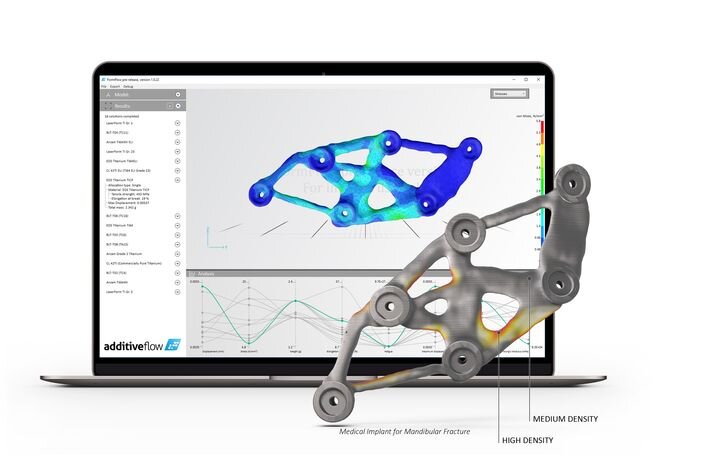

Additive Flow has been working on such a system, which they call “FormFlow”. The company, founded in 2017, has been in stealth mode until just recently when they have made public their concept and plan.

What’s different about Additive Flow’s approach? They say:

“We build AI-enabled design software to simultaneously optimise geometry and material decisions.”

This is the difference: they’re doing both geometry AND material decisions at the same time. Usually a generative tool will require you specify the material in advance, and then generate the mechanical design. However, it seems that FormFlow will do both at the same time.

This is obviously a better way to prepare a 3D model if multiple materials are possible. Most metal 3D printers today, however, can 3D print only in a single material. But for 3D printers with multiple material capability, this could be the ideal tool.

Take a look at this example of a multi-material 3D print made by Additive Flow:

![Example of a 3D printed part with gradient design generated by FormFlow [Source: Additive Flow]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb05085997bd.jpg)

It is a voxel-by-voxel 3D print, likely made on a Stratasys PolyJet device of some kind. They say:

“There were more than 750,043,872 voxels in making this object. At one material choice per second it would take over 24 years. How would they choose the best location for each material? Our software took less than a minute.

There may be limited interest in this type of software tool at the moment, but as the number of multi-material 3D printing options increases, the question of how to optimize multilateral designs will obviously increase. Thus Additive Flow is probably in a very good position, strategically.

The company says they intend on offering licenses for FormFlow later this year, but it is unclear at what pricing level. However, for those with the right equipment, the ability to generate radically different multi-material designs could be priceless.

Via Additive Flow