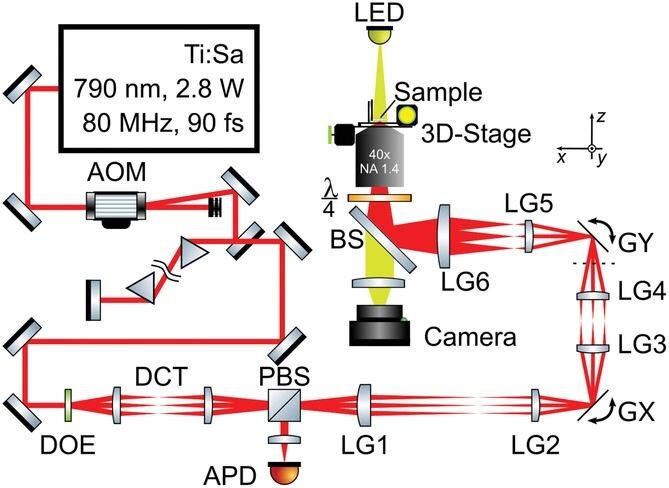

![A complex design for a parallel two-photon laser 3D printing system [Source: Wiley]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0509ee48a0.jpg)

Researchers have developed a complex system that is able to 3D print tiny structures at very high speeds.

There are few vendors providing microscopic 3D printing today, but those that do enable the production of incredible microscopic devices, lenses and components. Many use what’s called the “two photon” approach, where light is focused deep within a liquid photopolymer to solidify an object, voxel by voxel.

The problem is that the speed of such 3D printing can be slow, as the focal point of the two photon system must tediously traverse the entire structure. The researchers sought a means for performing this type of 3D printing in a more rapid manner.

Multifocus 2PP 3D Printing

They ended up developing the highly complex system shown above. It’s a bit hard to follow, but essentially a laser (top left box issuing an 80MHz 790nm beam) sends energy through a series of prisms, mirrors, splitters to create a “fan of beamlets”. Eventually, these arrive at a pair of 6mm galvanometric mirrors on the right, labeled “GX” and “GY”.

The galvo mirrors are operated up to a peak frequency of 2.8 kHz to distribute the beamlets to the desired areas on the scanning platform. Evidently the mirrors are being moved so quickly, the researchers had to construct a water cooling system to ensure they did not overheat!

Basically, they seem to have designed a system to enable parallel 3D printing using the two-photon process. This is quite an achievement. They call the process “Multifocus 2PP”.

Multifocus 2PP Speed

The researchers were able to 3D print a number of sample objects using the new process, including metamaterials, which could be a prime application for this technology.

How fast was the new process? The researchers were able to achieve the astonishing speed of ten million voxels per second — when 3D printing at sub-micrometer voxel sizes. While the eventual 3D prints made using this process will be physically small, the speed of production is nearly unbelievable.

Imagine if this speed could be duplicated for larger size 3D prints. For example, a 100mm figurine might consume 6m of filament, or about 14,500 cubic mm of material. If you were 3D printing this object at a resolution of 0.1mm, then this would represent something close to 14.5M voxels.

If scaled up, this system could produce this object in a mere 1.5 seconds. Of course, it cannot be scaled up to that level, as far as I know.

But I can dream.

Via Wiley