It was around 2014 that the consumer 3D printing bubble burst, causing the stocks of stalwarts like Stratasys and 3D Systems to plummet.

The firms quickly began shedding consumer-focused products in favor of devoting their resources to industrial projects.

Five years have since passed. Is the world ready for consumer 3D-printed goods this time around? One San Francisco-based startup, Gantri, is betting on it with the release of a design platform devoted to luxury 3D-printed home décor and a 3D printer meant to efficiently produce these items.

Direct to Consumer 3D Printing

Engineering.com spoke to Gantri CTO Christianna Taylor about the company’s operations and vision. Taylor has a PhD in aerospace engineering from the Georgia Institute of Technologyand worked in satellite design before moving to the San Francisco Bay Area. There, she joined the 3D printing startup to drive its future in technological development.

Founded two years ago, Gantri is focused specifically on selling modern home goods directly to consumers. In so doing, the firm aims to achieve benefits to both independent designers and customers. Designers are given the ability to bypass numerous hurdles in order to get their ideas to market.

“It can take years and hundreds of thousands of dollars to produce one product, and then you have no idea if people have any interest in that product. That development cost is so steep that most designers won’t see their designs on the market,” Taylor said.

In particular, Gantri estimated that, based on manufacturing 1,000 pieces of a specific design, tooling, combined with materials, engineering, testing and logistics, would rack up $100,000 in costs. This is why most items are produced in much larger batches than 1,000 and why there is such a large barrier to entry for both manufacturers and designers.

Those manufacturing costs are then passed onto customers. Those interested in luxury items are able to purchase products that might otherwise be too expensive if they were fabricated through the traditional mass manufacturing paradigm. “You and I are probably not looking at alight that can cost seven to eight hundred dollars because it’s out of our price range.”

3D printing opens up the possibility of cutting the line so that Gantri and its designers can sell products directly to consumers. Currently, the startup is focused on lighting modeled by roughly 30 designers located around the globe.

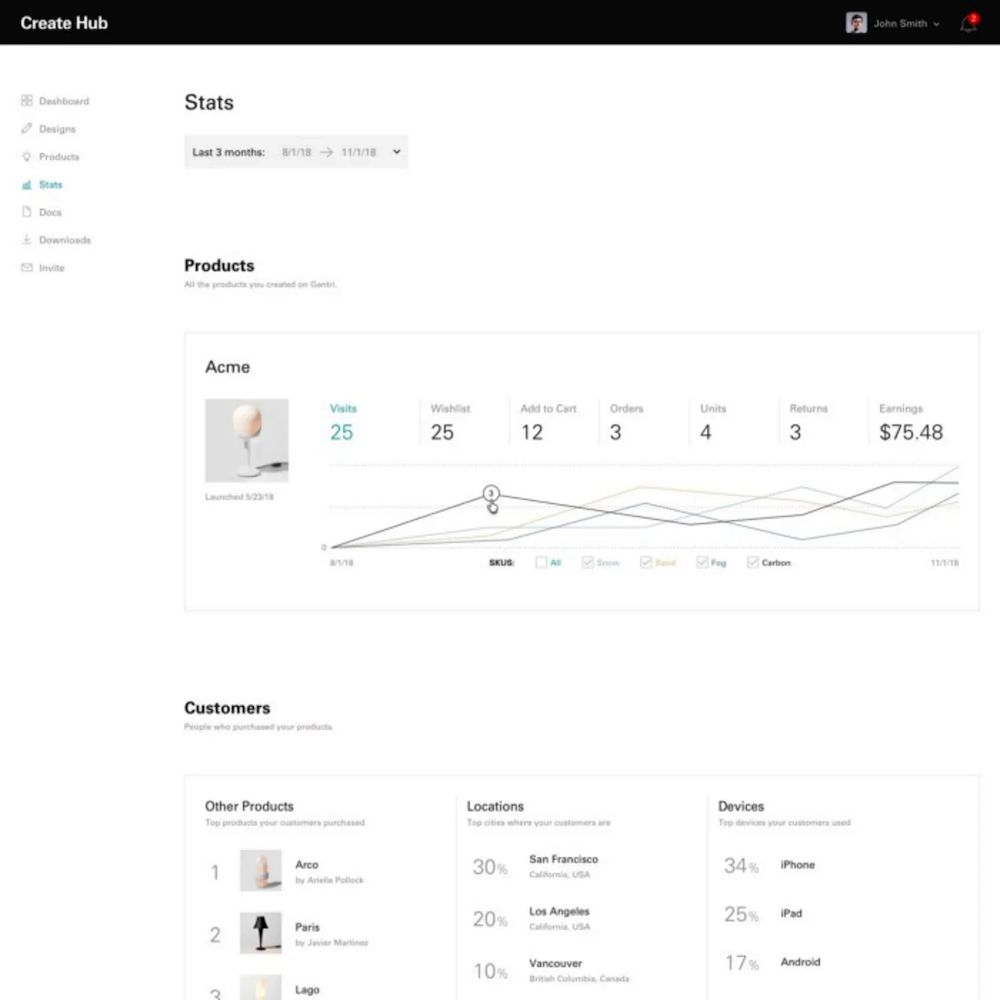

Once designers have been accepted onto the platform, they use Gantri’s Create Hub to download premodeled components that can be incorporated into the designers’ own unique lighting models. Artists have the choice of two PLA plastics, a translucent one for light diffusive parts and an opaque material for colored parts, which are finished with water-based paint.

Models are then optimized for 3D printing and quality by Gantri engineers, who work directly with engineers over the web. Using a built-in chatfeature, engineers send prototype photos and quality assurance results to designers as the item is finalized and readied for production.

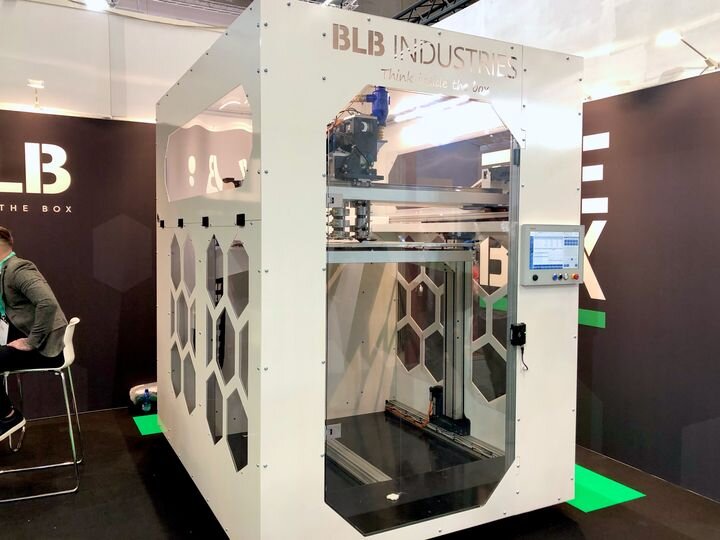

At this point in the process, the main components of the lights are 3D printed using Ultimaker 3D printers, while presourced components, such as light bulbs, fasteners and electrical cords are added to complete product assembly. The items are then shaped directly to the consumer.

With light hand-polishing and a paint finish, the products are meant to have the type of finish associated with high-priced home goods. This means smooth surfaces, with no noticeable layer lines or other roughness.

Taylor also noted that the materials used by Gantri are exclusively licensed to the company. The PLA combines the sustainability expected from corn starch-based plastic with features needed for consumer products. In this case, high temperature resistance and post-processability.

Product Quality

To determine the quality of Gantri’s products, engineering.com was shipped one table lamp. The translucent orb of the PyraSphere Table Light allows sufficient light to pour out of it so as to rival traditionally manufactured lamps. Its finish, too, is remarkable, given that the product was made with fused filament fabrication (FFF), a process that, like many 3D printing techniques, usually results in distinct layer lines.

When the light is turned on, barely perceptible gradations in the light diffusion can be noticed but would likely not be apparent to someone who wasn’t expecting layer lines caused by FFF. Because the printed base was coated in water-based paint, it was impossible to tell that it was made with a 3D printer.

Had this sample not been shipped to us at the expense of the company, it would have cost $128. Though IKEA’s prices might be difficult to beat, the price of Gantri’s goods are comparable to other modern home furnishing suppliers, such as Crate&Barrel. Beauty is in the eye of the beholder, however, so whether or not the designs meet your aesthetic requirements is up to you.

Read more at ENGINEERING.com

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.