![The AON-M2 High-Temperature 3D Printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb094a05944f.jpg)

AON 3D’s new AON-M2 3D printer can use a very wide array of possible materials.

The Montreal-based company has wisely focused their development on high-temperature 3D printing as that is a growing market and currently has relatively few options. Some of our contacts have already obtained one of AON 3D’s machines, and no doubt AON 3D will grow their client base with the new M2.

The high-temperature materials certified for 3D printing in the AON-M2 include PEEK, PEKK, ULTEM and PC. AON 3D describes them as the “World’s Strongest Polymers”, and they’re likely correct. The AON-M2 can also 3D print ABS, ASA, PA66, PA6, PA12, PETG, PSU, PPSU, TPC and TPU, as well as several support material options.

Aside from the materials capability, the AON-M2 boasts a significant build volume of 454 x 454 x 640 mm, one of the largest high-temperature build volumes we’ve seen. The layer height can be as small as 0.05mm for extreme resolution, but can also rise to 0.50mm for larger coarse objects printed in much shorter elapsed times.

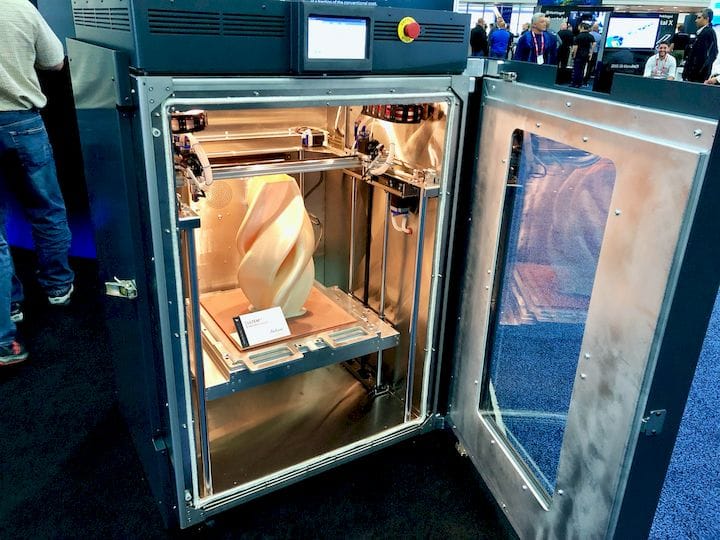

![Inside the AON-M2 high-temp 3D printer with an ULTEM print on the bed [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb094a085108.jpg)

The varying layer sizes are achieved through a set of swappable nozzles. Hardened steel nozzles are available in 0.25, 0.30, 0.40, 0.60, 0.80, 1.00 and 1.20 mm diameters. These are usable on both of the dual toolheads in the AON-M2.

About the dual extruders: these allow use of soluble support combined with a model material option, enabling easy printing of highly complex geometries. The need for difficult post-processing to remove intricate support structures is eliminated entirely if soluble support is used.

AON-M2 High-Temperature Components

The AON-M2’s build chamber is obviously fully enclosed due to the high heats involved. The hot end can reach 470C, while the print bed can hit an amazing 200C. The ambient atmosphere in the build chamber is heated up to 120C. These are significant temperatures and while they allow 3D printing of exotic materials, they also raise the need for good safety practices when operating the device.

One very interesting feature that you might not expect to find is that the stepper motors and hot ends are liquid cooled. This makes great sense, as they are normally within the very hot build chamber where the heat might wear them down more quickly if not cooled.

The standard features one might expect on a machine of this caliber are present, including WiFi networking, automated calibration, and even remote management through a web interface that’s usable on any device.

AON 3D does not produce their own dedicated slicing software for the AON-M2, but instead bundles the powerful Simplify3D slicing tool with the system. I’m not sure if AON 3D provides high-temperature materials slicing profiles for common materials with the software, but it would be a good idea if they did.

3D Printing in Lexan

![A large 3D print made of Lexan by AON 3D [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb094a0afb85.jpg)

When we checked out this machine we noticed they had 3D printed some unusual materials, most notably Lexan. This polymer is unusual in that it has an enormous impact strength and resists breaking even if severely deformed. This makes it suitable for many challenging 3D printing prototype projects.

As far as I know, this is the first instance of Lexan 3D printing I’ve witnessed. But it does demonstrate that the AON-M2 is indeed an open materials machine capable of handling very exotic materials indeed.

Via AON 3D

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.