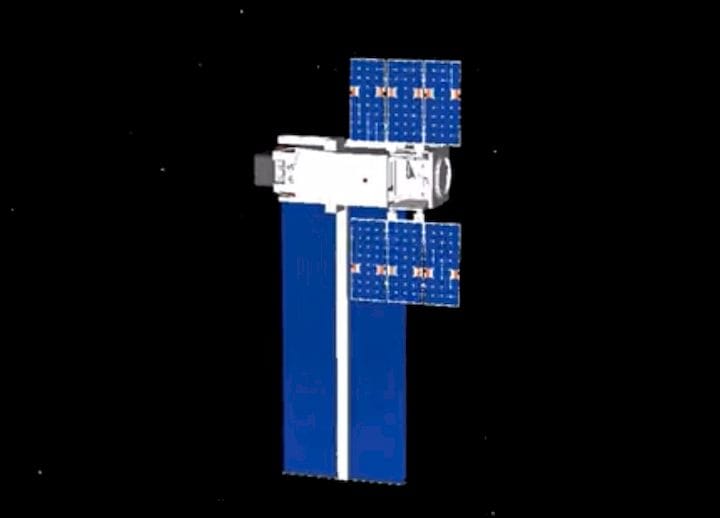

![The Archinaut space-based 3D printing demonstrator [Source: Made In Space]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb093f70e57d.jpg)

NASA has awarded US$73M to Made In Space to develop a space-based structural 3D printing system.

Made In Space has been working in this area for some time, having already demonstrated a “desktop” 3D printing capability on board the International Space Station with their micro-gravity-capable device.

This machine was more or less a conventional desktop FFF extrusion-style device, but with many tweaks and additions to enable it to be used safely and productively in the weightless environment of the space station. From what we understand, that device is now “packed away” after successfully performing a number of tests., while bioprinting experiments have gone to the ISS.

Since then Made In Space has been working on bigger and better things, most notably, the Archinaut concept. This is an entirely different concept from the previous on-ISS FFF 3D printer, as the Archinaut is a free-flying satellite that is intended to 3D print objects directly into the vacuum of space itself.

Made In Space has demonstrated Archinaut technology to NASA on the ground in vacuum chambers, where it was able to 3D print metal and other materials successfully. Now, we find that NASA has awarded the company (and their partners, Northrup Grumman and NASA JPL) US$73M to produce a real, orbital version of the Archinaut.

The mission is to print two giant ten-meter solar wings that can produce electrical power through solar cells. In this video you can see how it will work:

Electron Rocket To Launch Archinaut

Archinaut will launch on a Rocket Labs Electron rocket from their New Zealand launch pad sometime in the future. Of note is that Electron’s payload capacity is quite small, at only 150-225kg. That weight would have to hold the Made In Space 3D printer, power and control elements, as well as the materials for the printing. To put that in perspective, imagine a 20 x 1 meter metal structure that weighs 200kg.

This is a very important technology demonstration in NASA’s Technology Demonstration Mission project, as it could theoretically pioneer on-orbit construction methods. The problem today’s space vehicles and structures are faced with is that they all must fit within the fairing of a rocket.

Anything larger than the fairing must be collapsed somehow. A good example of this is the yet-to-be-launched James Webb Space Telescope, whose massive mirror had to be not only split into multiple segments, but also folded up like a flower in order to launch.

Archinaut 3D Prints Structures

A microgravity environment means structures can be large and spindly, much more so than Earth-based structures. But that’s not easy with the rocket problem.

If the Archinaut technology works, then these challenges could be largely eliminated, and we could see larger versions of Archinaut in the future being used to build enormous science fiction-level structures in orbit or beyond.

Made In Space is also working on a number of related technologies. For example, they also are developing a system for assembling parts together. This, combined with a printing capability, means they could be able to build very large structures.

The possibilities are limitless.

Via NASA and Made In Space

Years of experimentation are leading to affirmation: 3D printing in space, for in-space use, is looking viable.