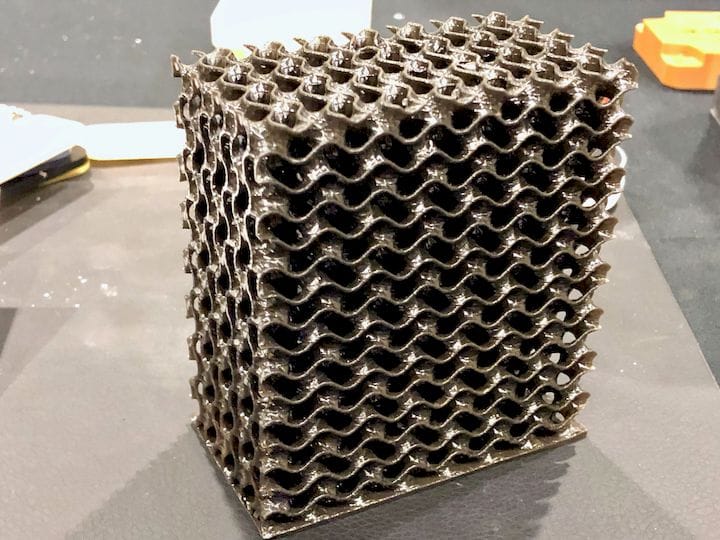

![An extremely strong fiber-reinforced complex 3D print made by Fortify [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/fortify-mesh-print-1_img_5eb096baa7b9c.jpg)

A startup is using magnetic fields to 3D print extremely strong objects.

You likely have not heard of Fortify, but you certainly will be hearing a lot more from them in the future. The Boston-based startup, founded by Joshua Martin in 2016 based on his academic thesis, has developed a highly unusual technique to 3D print strongly reinforced objects using magnetic fields in an ingenious manner.

The company has patented their process, and after already receiving venture capital to get going, they are working on a Series A fundraising round that could be announced soon.

![Fortify Founder and CEO Joshua Martin [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb096bb10383.jpg)

It’s all about the inclusion of reinforcing fibers within the print material. Of course, chopped fibers are a mainstay of strong materials these days, as it’s now relatively common to use them. But although they do indeed strengthen prints, they do not leverage the full strengthening capabilities of the glass or carbon fibers.

Why not? It’s because the fibers are randomly oriented in typical composite materials. These chopped fibers are oriented arbitrarily throughout the material.

But what if the fibers could be oriented in a particular direction? If so, the part could be greatly strengthened, at least in the fiber direction.

Fortify has figured out a practical way to actually do this. They can orient fibers within a 3D print. Here’s how it works:

-

Fibers are treated with a ferridic coating

-

Fibers are chopped fine

-

Fibers are mixed with a liquid photopolymer

-

Composite photopolymer is ready for 3D printing

-

Magnetic field is generated by the Fortify 3D printer

-

Fibers, being ferridic-coated, orient themselves according to the magnetic field

-

Light source is selectively applied to the photopolymer resin (DLP in this case)

-

Photopolymer solidifies, with the fibers oriented as per the magnetic field direction

-

Process repeats, layer by layer, to complete the print

I know what you are thinking: what’s the point of having all fibers oriented a particular way on each layer? There are few engineering scenarios where that would be required.

It turns out that Fortify’s solution is far more sophisticated.

They can solidify only a portion of the layer, and then re-orient the magnetic field to a particular direction and perform another solidification event on another portion of a layer. Thus, they can control the orientation of fibers to literally each pixel of each layer, in theory. However, in practice that would slow down the print to an extraordinary degree.

But this hardware capability leads into the software question: how do you determine the best orientation for a given 3D model? Fortify has two methods of doing so using their software (which must be used as it is required to handle the magnetic field changes).

One way is to have their software automatically recognize basic 3D shapes. For example, if it sees a cylinder, it will automatically set up the print job to have fibers oriented to wrap the cylinder. Long segments would have fibers aligned appropriately, etc.

The other method is more sophisticated. Fortify connects with CAD tools to absorb finite element analyses. These are mathematical simulations of stress, typically mechanical. The Fortify software then transforms this information into an optimal orientation for the fibers, as assigned by the changing magnetic field. We saw a 3D printed turbine impeller, which had fibers aligned appropriately throughout its twisting blades. Imagine the possibilities!

While the Fortify magnetic process will inevitably slow print speeds down — because each layer will necessarily take longer if many orientations are required — it does produce extremely strong 3D prints. Fortify suggests they are an intermediate strength level somewhere between normal fiber-reinforced 3D prints and full metal 3D prints, and we don’t disagree, having handled some of their test prints.

![A reinforced injection mold 3D printed by Fortify [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb096bb6898b.jpg)

There will be a number of applications for such strong prints, and one of the most notable will surely be injection molds. Today the choice is between the very expensive and traditional metal CNC-cut molds and the faster-to-make 3D printed molds that don’t last for very many injection shots. The Fortify technology might change the state of injection molding in a significant way.

Today Fortify does not yet offer the machine, but their team of 14 is working hard towards that goal, with a target of 8-12 months away. Currently it seems some friendly clients are helping alpha test the process by submitting requests to Fortify for printing on their prototype machines. We’re told this testing is working very well.

Fortify’s process is perhaps one of the most interesting we’ve seen recently, and if they can produce a functional 3D printer, they may add a new class of device to the world of 3D printing.

Watch for them in the future.

Via Fortify

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.